Candying preserves fruit by slowly simmering it in sugar syrup, which replaces water content and inhibits microbial growth. Vacuum candying enhances this process by using reduced pressure to allow syrup infusion at lower temperatures, preserving fruit texture and color more effectively. This method results in higher quality preserved fruit with improved flavor retention and longer shelf life.

Table of Comparison

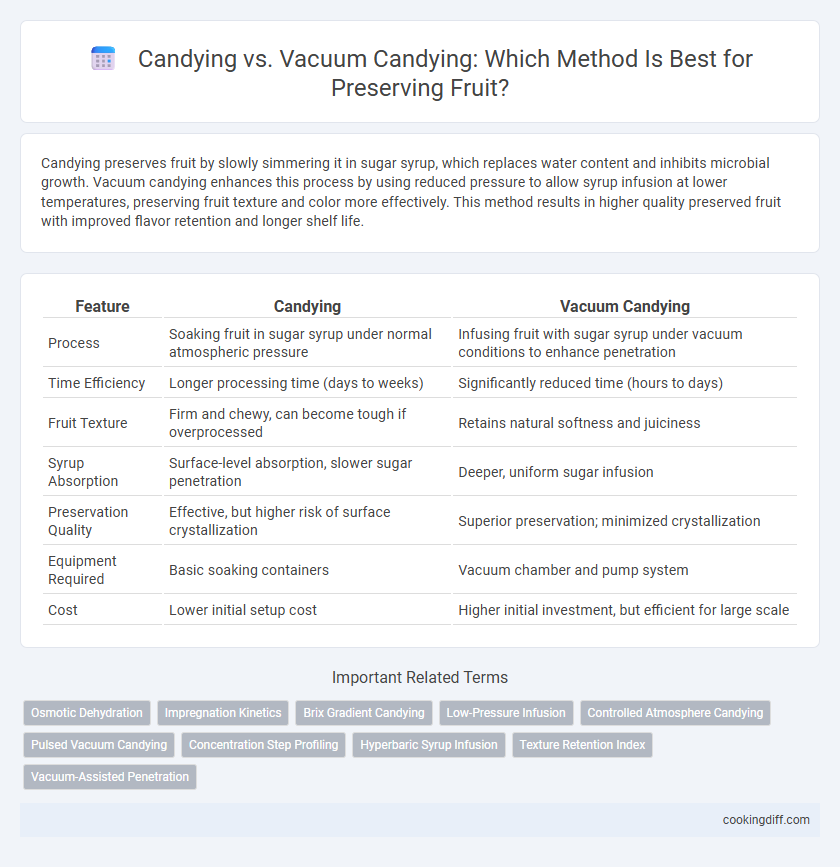

| Feature | Candying | Vacuum Candying |

|---|---|---|

| Process | Soaking fruit in sugar syrup under normal atmospheric pressure | Infusing fruit with sugar syrup under vacuum conditions to enhance penetration |

| Time Efficiency | Longer processing time (days to weeks) | Significantly reduced time (hours to days) |

| Fruit Texture | Firm and chewy, can become tough if overprocessed | Retains natural softness and juiciness |

| Syrup Absorption | Surface-level absorption, slower sugar penetration | Deeper, uniform sugar infusion |

| Preservation Quality | Effective, but higher risk of surface crystallization | Superior preservation; minimized crystallization |

| Equipment Required | Basic soaking containers | Vacuum chamber and pump system |

| Cost | Lower initial setup cost | Higher initial investment, but efficient for large scale |

Introduction to Candying and Vacuum Candying

Candying is a preservation technique that involves soaking fruit in sugar syrup to replace water content, enhancing shelf life and sweetness. Vacuum candying accelerates this process by applying low pressure to infuse the syrup more efficiently, reducing processing time and improving fruit texture.

- Candying - Uses prolonged immersion in sugar syrup to preserve fruit by replacing moisture with sugar.

- Vacuum Candying - Applies a vacuum environment to speed syrup absorption and maintain fruit integrity.

- Benefits - Vacuum candying offers a quicker process with better retention of color and flavor compared to traditional candying.

Historical Background of Fruit Preservation

Candying, a traditional method dating back to ancient civilizations, preserves fruit by slowly replacing its water content with sugar, creating a sweet, shelf-stable product. Vacuum candying, a modern innovation, accelerates this process by using reduced pressure to infuse sugar syrup more rapidly, retaining fruit texture and flavor better than conventional methods. Both techniques reflect humanity's evolving approach to fruit preservation, balancing shelf life with taste and nutritional retention.

The Science Behind Candying Fruits

Candying fruits involves saturating them with sugar to inhibit microbial growth through osmotic pressure, while vacuum candying enhances this process by removing air and allowing deeper sugar penetration. The vacuum method accelerates preservation and retains fruit texture more effectively by lowering the boiling point of the sugar solution.

- Osmotic Dehydration - Sugar draws out moisture from fruit cells, reducing water activity that bacteria and molds need to thrive.

- Vacuum Pressure - Evacuating air from fruit tissue opens cellular pathways for sugar molecules to infuse more thoroughly.

- Boiling Point Reduction - Vacuum environment lowers the temperature required to cook sugar syrup, preserving more natural fruit flavor and color.

How Traditional Candying Works

| Traditional candying preserves fruit by slowly infusing it with sugar through repeated boiling and soaking in sugar syrup, which gradually replaces the fruit's natural water content. This method relies on osmosis to draw out moisture, creating a dense, sweet exterior that inhibits microbial growth. The process can take several days to weeks, ensuring thorough sugar penetration for long-term preservation. |

Understanding Vacuum Candying Technology

Vacuum candying technology enhances fruit preservation by removing air and reducing pressure, which accelerates sugar infusion and prevents oxidation. This method retains the fruit's natural color, texture, and nutritional value more effectively than traditional candying.

Vacuum candying allows for faster processing times and deeper penetration of the syrup, resulting in improved flavor absorption and shelf life. By controlling the vacuum level, manufacturers can optimize the candying process for various fruit types, ensuring consistent quality and reducing waste.

Key Differences: Candying vs Vacuum Candying

Candying preserves fruit by soaking it in sugar syrup, allowing gradual absorption of sugar to prevent spoilage. Vacuum candying accelerates this process by removing air under reduced pressure, enhancing sugar penetration and retaining fruit texture more effectively.

- Sugar Absorption Rate - Candying relies on slow diffusion, whereas vacuum candying speeds up sugar uptake by reducing pressure.

- Texture Retention - Vacuum candying better maintains fruit firmness compared to traditional candying.

- Processing Time - Vacuum candying significantly reduces the time needed to candy fruit versus conventional methods.

Vacuum candying offers a more efficient and texturally superior method for fruit preservation compared to standard candying techniques.

Flavor and Texture Comparison

Candying preserves fruit by infusing sugar, resulting in a sweet flavor and a tender, slightly firm texture that retains some natural fruit characteristics. Vacuum candying enhances flavor absorption by creating a low-pressure environment, allowing sugar to penetrate more deeply and evenly.

The texture of vacuum-candied fruit tends to be more uniform and softer due to the faster and more efficient sugar infiltration. Flavor intensity is generally higher in vacuum-candied fruit, providing a richer and more concentrated taste compared to traditional candying methods.

Nutritional Effects of Each Method

How do candying and vacuum candying differ in their nutritional effects on preserved fruit? Candying often leads to higher sugar content retention but can degrade heat-sensitive vitamins such as vitamin C. Vacuum candying preserves more nutrients by reducing oxidation and minimizing heat exposure during the process.

Practical Applications and Suitability

Candying preserves fruit by saturating it with sugar, making it ideal for small-scale or traditional applications where texture and flavor are prioritized. Vacuum candying enhances this process by reducing pressure, allowing sugar to penetrate fruit more rapidly and uniformly, which suits large-scale industrial production. Practical use of vacuum candying optimizes efficiency and shelf life, while traditional candying remains favored for artisanal qualities and home preservation.

Related Important Terms

Osmotic Dehydration

Candying uses osmotic dehydration to preserve fruit by immersing it in concentrated sugar syrup, which draws out water and replaces it with sugar to inhibit microbial growth. Vacuum candying enhances this process by applying reduced pressure, accelerating osmotic dehydration and improving sugar penetration for more efficient preservation and better texture retention.

Impregnation Kinetics

Candying involves sugar impregnation through osmotic diffusion, which is generally slower and less uniform compared to vacuum candying; vacuum candying enhances impregnation kinetics by removing air from the fruit matrix under reduced pressure, allowing faster and deeper penetration of sugar syrup. This accelerated mass transfer in vacuum candying significantly improves texture retention and preservation efficacy by optimizing sugar concentration gradients and reducing processing times.

Brix Gradient Candying

Candying preserves fruit by gradually infusing sugar through a Brix gradient, replacing water within the fruit to inhibit microbial growth and enhance shelf life. Vacuum candying accelerates this process by reducing pressure, allowing deeper sugar penetration and more uniform candying, resulting in better preservation and texture retention.

Low-Pressure Infusion

Low-pressure infusion in vacuum candying accelerates syrup penetration by reducing pressure, enabling faster and more uniform sugar absorption compared to traditional candying methods. This technique preserves fruit texture and flavor while lowering processing time and energy consumption.

Controlled Atmosphere Candying

Controlled Atmosphere Candying enhances fruit preservation by regulating oxygen, carbon dioxide, and humidity levels, reducing oxidation and microbial growth compared to traditional candying methods. This technique maintains fruit texture and color more effectively than vacuum candying, which primarily focuses on pressure reduction without optimizing atmospheric composition.

Pulsed Vacuum Candying

Pulsed vacuum candying enhances fruit preservation by alternately applying vacuum pressure and atmospheric pressure, improving syrup infusion and reducing processing time compared to traditional candying methods. This technique increases moisture removal efficiency and achieves uniform sugar distribution, resulting in better texture retention and extended shelf life for candied fruits.

Concentration Step Profiling

Candying preserves fruit by infusing it with sugar through a concentration step where osmotic pressure drives water out and sugar in, creating a stable, sweet product. Vacuum candying enhances this process by reducing pressure to lower boiling points, accelerating sugar penetration and moisture removal, resulting in improved texture and flavor retention.

Hyperbaric Syrup Infusion

Hyperbaric syrup infusion enhances fruit preservation by using pressure to force syrup deep into fruit tissues, resulting in uniform sweetness and extended shelf life. Unlike traditional candying, vacuum candying relies on reduced pressure to remove air and improve syrup penetration, but hyperbaric methods achieve more consistent infusion and texture retention.

Texture Retention Index

Candying preserves fruit by immersing it in sugar syrup, resulting in a Texture Retention Index (TRI) that balances firmness and chewiness, while Vacuum Candying enhances TRI significantly by reducing sugar penetration time and minimizing cell wall damage, maintaining a more natural texture. Studies show Vacuum Candying can improve TRI by up to 30% compared to traditional candying methods, making it superior for texture-sensitive fruits.

Candying vs Vacuum Candying for preserving fruit. Infographic

cookingdiff.com

cookingdiff.com