Candying preserves fruits or pet treats by soaking them in sugar syrup, creating a sweet, glossy coating that enhances flavor and texture. Dehydrator-assisted candying uses controlled low heat to remove moisture evenly, speeding up the drying process while maintaining the candying quality. This method offers a more consistent result and reduces preparation time compared to traditional candying techniques.

Table of Comparison

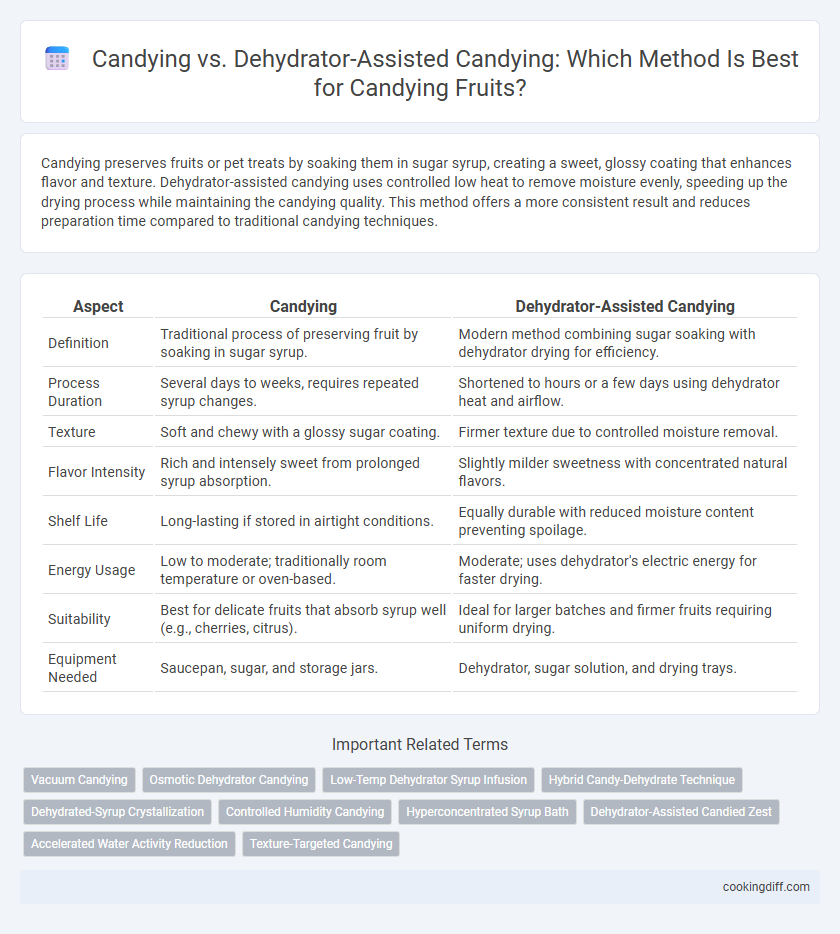

| Aspect | Candying | Dehydrator-Assisted Candying |

|---|---|---|

| Definition | Traditional process of preserving fruit by soaking in sugar syrup. | Modern method combining sugar soaking with dehydrator drying for efficiency. |

| Process Duration | Several days to weeks, requires repeated syrup changes. | Shortened to hours or a few days using dehydrator heat and airflow. |

| Texture | Soft and chewy with a glossy sugar coating. | Firmer texture due to controlled moisture removal. |

| Flavor Intensity | Rich and intensely sweet from prolonged syrup absorption. | Slightly milder sweetness with concentrated natural flavors. |

| Shelf Life | Long-lasting if stored in airtight conditions. | Equally durable with reduced moisture content preventing spoilage. |

| Energy Usage | Low to moderate; traditionally room temperature or oven-based. | Moderate; uses dehydrator's electric energy for faster drying. |

| Suitability | Best for delicate fruits that absorb syrup well (e.g., cherries, citrus). | Ideal for larger batches and firmer fruits requiring uniform drying. |

| Equipment Needed | Saucepan, sugar, and storage jars. | Dehydrator, sugar solution, and drying trays. |

Introduction to Candying and Dehydrator-Assisted Candying

What distinguishes traditional candying from dehydrator-assisted candying in cooking? Candying preserves fruits by soaking them in sugar syrup, enhancing sweetness and shelf life. Dehydrator-assisted candying uses controlled drying technology to achieve a similar effect with improved texture and reduced processing time.

Overview of Traditional Candying Methods

| Traditional candying methods involve soaking fruit in sugar syrup for extended periods, allowing the sugar to gradually replace the fruit's moisture while preserving its texture and flavor. This process typically spans several days to weeks, achieving a balance of sweetness and moisture retention without the need for temperature control devices. These methods rely on natural diffusion and osmosis to infuse sugar, making them labor-intensive but producing rich, classic candied fruits. |

What is Dehydrator-Assisted Candying?

Dehydrator-assisted candying is a method that uses a food dehydrator to slowly remove moisture from fruits while infusing them with sugar, resulting in a chewier texture than traditional candying. This technique provides consistent low heat and controlled airflow, promoting even drying and enhancing flavor retention. Compared to conventional candying, it reduces the risk of crystallization and allows for better preservation of natural fruit colors and nutrients.

Ingredient Preparation: Traditional vs Dehydrator-Assisted

Traditional candying involves soaking fruits in sugar syrup to gradually replace water content, preserving texture and flavor naturally. Dehydrator-assisted candying uses controlled heat to remove moisture before or during sugar infusion, speeding up the process and enhancing shelf life. Ingredient preparation with dehydrators allows for uniform drying, reducing spoilage and improving consistent sugar absorption compared to traditional methods.

Time and Efficiency Comparison

Candying typically requires longer preparation and cooking times compared to dehydrator-assisted candying, which significantly reduces the time needed for moisture removal. The efficiency of a dehydrator allows for more consistent results with less manual intervention, making it a preferred method for preserving fruits and enhancing flavors.

- Candying Time - Traditional candying can take several hours to days depending on the fruit, due to repeated boiling and soaking steps.

- Dehydrator-Assisted Time - Dehydrator-assisted candying expedites drying, cutting down the process to a few hours by using controlled temperature and airflow.

- Efficiency - Dehydrators provide uniform moisture reduction, improving texture and shelf life while reducing energy use and labor.

Flavor and Texture Differences

Candying preserves the natural moisture of fruits, resulting in a richer, sweeter flavor and a soft, chewy texture. Dehydrator-assisted candying intensifies sweetness but often yields a firmer, less pliable texture due to moisture loss.

- Candying enhances flavor retention - The slow absorption of sugar syrup maintains the fruit's natural taste nuances.

- Dehydrator-assisted candying increases shelf life - Reduced moisture content minimizes spoilage but alters texture.

- Texture contrast is significant - Traditional candying produces tender chewiness while dehydrator methods create a denser bite.

Nutrient Retention in Both Methods

Candying preserves the natural sugars and some vitamins by slowly infusing fruit with sugar syrup, but heat exposure can degrade heat-sensitive nutrients like vitamin C. Dehydrator-assisted candying uses controlled low heat, reducing nutrient loss while concentrating flavors through dehydration.

Studies show dehydrator-assisted candying retains more antioxidants and minerals compared to traditional candying, as lower drying temperatures minimize nutrient breakdown. Both methods extend shelf life, yet dehydrator-assisted candying offers enhanced nutrient retention and texture preservation.

Equipment and Cost Considerations

Candying requires basic kitchen tools like a saucepan and thermometer, making it accessible and cost-effective for home cooks. Dehydrator-assisted candying involves investing in a specialized food dehydrator, which can be more expensive upfront but offers precise temperature control.

Traditional candying uses less equipment overall, reducing initial costs and waste. The dehydrator's energy consumption adds to ongoing expenses, but it can improve consistency and reduce manual labor during the candying process.

Versatility and Recipe Applications

Candying offers traditional flavor infusion and texture control, making it ideal for delicate fruits and simple recipes. Dehydrator-assisted candying enhances versatility by allowing precise moisture control, which expands its use to a wider variety of ingredients and complex culinary techniques.

- Candying maintains natural fruit integrity - preserves original shape and imparts a glossy, sweet exterior suitable for garnishes.

- Dehydrator-assisted candying improves drying efficiency - ensures consistent moisture removal to prevent spoilage in thicker or denser items.

- Candying suits classic recipes - ideal for traditional confections like candied citrus peels and cherries.

Both methods adapt well to recipes requiring texture and sweetness customization, but dehydrator-assisted candying provides greater experimentation opportunities in modern cuisine.

Related Important Terms

Vacuum Candying

Vacuum candying enhances traditional candying by using reduced pressure to accelerate syrup penetration into fruits, preserving texture and intensifying flavor more efficiently than conventional dehydration methods. This technique minimizes nutrient loss and shortens processing time compared to dehydrator-assisted candying, making it a superior choice for high-quality confectionery production.

Osmotic Dehydrator Candying

Osmotic dehydrator candying uses a controlled osmosis process to remove moisture from fruits, enhancing flavor concentration and texture without relying on high heat, unlike traditional candying methods. This technique preserves color and nutrients more effectively while achieving a balanced sweetness, making it an innovative alternative in confectionery production.

Low-Temp Dehydrator Syrup Infusion

Low-temp dehydrator syrup infusion enhances candying by gradually infusing sugar syrup into fruit at controlled temperatures, preserving texture and flavor while achieving superior sweetness penetration compared to traditional candying methods. This technique reduces the risk of crystallization and maintains moisture balance, resulting in a tender, evenly sweetened confection.

Hybrid Candy-Dehydrate Technique

The hybrid candy-dehydrate technique combines traditional candying with controlled dehydration, enhancing flavor infusion while reducing moisture content for longer shelf life and improved texture. This method optimizes sugar crystallization and moisture removal, resulting in a balanced, chewy consistency superior to conventional candying or dehydrator-only processes.

Dehydrated-Syrup Crystallization

Dehydrator-assisted candying enhances syrup penetration while controlling moisture content, reducing the risk of unwanted crystallization compared to traditional candying methods. Precise temperature and humidity regulation in dehydrators prevent sugar crystallization, resulting in a smoother, clearer candied product with improved texture and extended shelf life.

Controlled Humidity Candying

Controlled humidity candying preserves fruit texture and flavor by maintaining optimal moisture levels during the candying process, enhancing sugar absorption and preventing crystallization. Compared to dehydrator-assisted candying, controlled humidity methods offer more precise environment regulation, resulting in consistently tender, well-infused candied fruits.

Hyperconcentrated Syrup Bath

Candying using a hyperconcentrated syrup bath intensifies flavor absorption and preserves fruit texture by minimizing water content during the process. Dehydrator-assisted candying complements this method by evenly removing moisture after syrup immersion, enhancing shelf life and preventing crystallization.

Dehydrator-Assisted Candied Zest

Dehydrator-assisted candied zest enhances traditional candying by using low heat airflow to efficiently remove moisture while preserving intense citrus flavor and vibrant color. This method reduces drying time compared to conventional stovetop candying, resulting in a superior texture with a perfect balance of chewiness and crispness.

Accelerated Water Activity Reduction

Candying accelerates water activity reduction through osmotic dehydration by immersing fruit in concentrated sugar syrup, which draws out moisture more rapidly than traditional drying. Dehydrator-assisted candying combines heat and airflow to further expedite moisture loss, enhancing shelf life and texture by uniformly reducing water content at a controlled rate.

Candying vs Dehydrator-Assisted Candying for cooking. Infographic

cookingdiff.com

cookingdiff.com