Candying preserves fruits by replacing water with sugar, significantly reducing water activity and inhibiting microbial growth, which extends shelf life. Water activity control involves regulating moisture levels to prevent spoilage and maintain texture without necessarily using high sugar concentrations. Compared to water activity control alone, candying provides a more stable environment for shelf-stable sweets by creating a sugar-saturated barrier that limits both microbial and enzymatic deterioration.

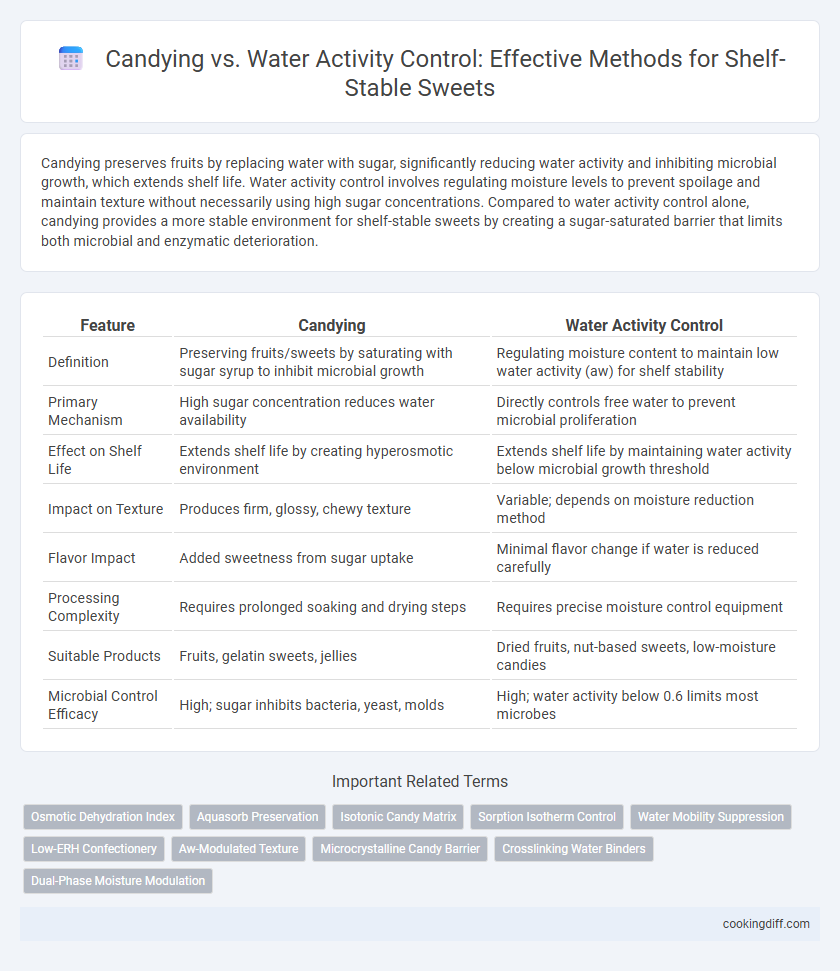

Table of Comparison

| Feature | Candying | Water Activity Control |

|---|---|---|

| Definition | Preserving fruits/sweets by saturating with sugar syrup to inhibit microbial growth | Regulating moisture content to maintain low water activity (aw) for shelf stability |

| Primary Mechanism | High sugar concentration reduces water availability | Directly controls free water to prevent microbial proliferation |

| Effect on Shelf Life | Extends shelf life by creating hyperosmotic environment | Extends shelf life by maintaining water activity below microbial growth threshold |

| Impact on Texture | Produces firm, glossy, chewy texture | Variable; depends on moisture reduction method |

| Flavor Impact | Added sweetness from sugar uptake | Minimal flavor change if water is reduced carefully |

| Processing Complexity | Requires prolonged soaking and drying steps | Requires precise moisture control equipment |

| Suitable Products | Fruits, gelatin sweets, jellies | Dried fruits, nut-based sweets, low-moisture candies |

| Microbial Control Efficacy | High; sugar inhibits bacteria, yeast, molds | High; water activity below 0.6 limits most microbes |

Understanding Candying: Preservation Through Sugar

How does candying influence the shelf stability of sweets compared to water activity control? Candying preserves sweets by infusing them with high concentrations of sugar, which binds free water and creates an inhospitable environment for microbial growth. Unlike water activity control that reduces moisture content directly, candying leverages osmotic pressure to extend shelf life while enhancing flavor and texture.

The Science Behind Water Activity in Sweets

Water activity (aw) is a critical parameter in candying that measures the free moisture available for microbial growth and chemical reactions, impacting shelf stability. Controlling water activity below 0.6 in shelf-stable sweets inhibits spoilage and extends product longevity by preventing microbial proliferation.

Candying reduces water activity by replacing free water with concentrated sugar, creating an environment unsuitable for microbial activity. This sugar-induced water activity control differs from simple dehydration methods, as it stabilizes texture and flavor while preserving sweetness and moisture content in the final product.

Candying vs Water Activity Control: Key Differences

Candying involves infusing sugars into fruits or other products to preserve them and enhance sweetness, creating a high-sugar environment that inhibits microbial growth. Water activity control focuses on reducing available moisture in sweets through drying or ingredient adjustment to prevent spoilage without necessarily increasing sugar content. Both methods aim to extend shelf life, but candying relies on sugar saturation, while water activity control targets moisture reduction for stability.

How Water Activity Influences Shelf Life

Candying reduces water activity by infusing fruits or sweets with concentrated sugar solutions, creating an inhospitable environment for microbial growth and extending shelf life. Water activity (a_w) directly influences the stability of shelf-stable sweets; lower a_w values inhibit enzymatic reactions and microbial spoilage, preserving texture and flavor. Monitoring and controlling water activity is essential for predicting product shelf life and ensuring food safety in candying processes.

Traditional Candying Techniques and Their Limitations

Traditional candying techniques rely on high sugar concentrations to inhibit microbial growth by reducing water activity, which helps preserve shelf-stable sweets. However, these methods often lead to texture and flavor limitations as excessive sugar can crystallize and cause product quality degradation.

- Sugar saturation limits preservation - Excessive sugar levels create a supersaturated environment that can crystallize over time, affecting texture.

- Water activity control is imprecise - Traditional candying does not uniformly regulate water activity, resulting in inconsistency across batches.

- Flavor complexity is restricted - High sugar content masks delicate flavor profiles, limiting product variety.

Modern shelf-life extension increasingly favors precise water activity control over solely relying on sugar concentration.

Modern Water Activity Control Methods in Confectionery

Modern water activity control methods in confectionery utilize advanced sensors and hygroscopic ingredients to precisely regulate moisture levels, enhancing the shelf stability of sweets. These techniques ensure optimal texture and prevent microbial growth without compromising flavor.

Compared to traditional candying, which relies on sugar saturation to reduce water activity, contemporary methods focus on real-time monitoring and adjustment of water content. Innovations such as moisture meters and controlled-atmosphere packaging significantly extend shelf life while maintaining product quality. Integrating water activity control with ingredient formulation customizes preservation strategies for diverse confectionery products.

Texture and Flavor: Effects of Candying and Water Activity

| Texture: Candying enhances shelf-stable sweets by creating a firm, crystalline structure through sugar infusion, reducing water activity and extending shelf life. Water activity control alone maintains texture by inhibiting microbial growth but may result in softer or chewier products compared to candying. The crystallization in candying provides a distinct, crisp mouthfeel absent in solely water activity-controlled confections. |

| Flavor: Candying intensifies flavor profiles by concentrating natural sugars and preserving aromatic compounds within the candy matrix, whereas water activity control helps retain freshness without significantly altering taste. Reduced water activity limits enzymatic and microbial degradation, maintaining flavor stability over time but without the pronounced sweetness and aroma enhancement candying imparts. Combining candying with water activity management achieves optimal flavor preservation for shelf-stable sweets. |

Safety and Microbial Stability in Shelf-Stable Sweets

Candying preserves shelf-stable sweets by creating a high sugar concentration that inhibits microbial growth, effectively reducing water activity and enhancing safety. This method ensures long-term stability without relying solely on water activity control, which measures free water available for microbial proliferation.

While water activity control is crucial for preventing spoilage, candying combines sugar infusion and dehydration, offering dual protection against pathogens. The synergistic effect of reduced water activity and high osmotic pressure from candying maintains microbial stability and extends shelf life in confectionery products.

Choosing the Right Method for Your Sweet Product

Candying enhances shelf stability by infusing sugar into fruit, reducing water activity naturally, while water activity control uses precise moisture management to inhibit microbial growth. Selecting between these methods depends on product texture, flavor preservation, and production scalability.

- Candying - Involves soaking or cooking fruit in concentrated sugar syrup to replace water content, creating a sweet, shelf-stable product with longer preservation.

- Water Activity Control - Focuses on regulating moisture levels through drying or adding humectants to maintain low microbial risk without significantly altering texture.

- Method Selection - Consider the desired sweetness, texture, and processing equipment availability to choose the optimal preservation technique for your sweet product.

Related Important Terms

Osmotic Dehydration Index

Candying relies on osmotic dehydration, where the Osmotic Dehydration Index (ODI) measures the effectiveness of sugar infusion in reducing water content, enhancing shelf stability. Unlike water activity control that adjusts moisture levels to inhibit microbial growth, a higher ODI in candying indicates superior sugar penetration and moisture removal, crucial for preserving texture and prolonging sweetness in shelf-stable confections.

Aquasorb Preservation

Aquasorb Preservation enhances candying by effectively reducing water activity levels, extending the shelf life of shelf-stable sweets without compromising texture or flavor. Compared to traditional water activity control methods, Aquasorb offers superior moisture regulation, preventing microbial growth and maintaining product quality over time.

Isotonic Candy Matrix

Isotonic candy matrices leverage precise sugar concentration to balance water activity (a_w) around 0.85, optimizing microbial stability without excessive moisture loss typical in traditional candying. This equilibrium enhances shelf-life by maintaining moisture content while preventing crystallization and microbial growth in shelf-stable sweets.

Sorption Isotherm Control

Candying enhances shelf-stability by reducing water activity through syrup infusion, creating a moisture equilibrium that prevents microbial growth. Sorption isotherm control precisely monitors the candy's moisture content, ensuring optimal water activity levels to maintain texture and prolong shelf life.

Water Mobility Suppression

Candying preserves fruit by infusing sugar to reduce water mobility, effectively suppressing microbial growth and enzymatic reactions for extended shelf stability. Water activity control relies on lowering free water content but candying achieves superior water mobility suppression through osmotic pressure, enhancing the texture and safety of shelf-stable sweets.

Low-ERH Confectionery

Low-ERH confectionery relies on candying techniques that reduce water activity by embedding sugars in a crystalline matrix, creating a shelf-stable product with enhanced texture and sweetness. Water activity control methods focus on moisture reduction through drying or humectants but may lack the flavorful complexity and structural benefits provided by traditional candying processes.

Aw-Modulated Texture

Candying enhances shelf stability by reducing water activity (Aw) through sugar infusion, creating an Aw-modulated texture that balances chewiness and firmness in sweets. This controlled water activity prevents microbial growth while maintaining the desired sensory qualities, unlike water activity control methods that may compromise texture integrity.

Microcrystalline Candy Barrier

Microcrystalline candy barrier creates a dense, stable matrix that limits water mobility, enhancing shelf stability more effectively than traditional water activity control methods. This structural integrity reduces microbial growth and moisture-induced texture degradation, ensuring prolonged freshness in shelf-stable sweets.

Crosslinking Water Binders

Candying enhances shelf stability by using sugar to create a dense matrix that effectively crosslinks water binders, limiting free water activity and preventing microbial growth. This crosslinking mechanism surpasses traditional water activity control methods by physically immobilizing water molecules, ensuring longer-lasting texture and flavor retention in shelf-stable sweets.

Candying vs Water activity control for shelf-stable sweets. Infographic

cookingdiff.com

cookingdiff.com