Manual sugar sifters offer precise control and are ideal for small-scale candy coating, allowing artisans to evenly dust each piece by hand. Automated sugar dusting machines increase efficiency and consistency, making them perfect for large production runs where uniform coverage is essential. Choosing between these methods depends on production volume, desired precision, and budget constraints in candy coating processes.

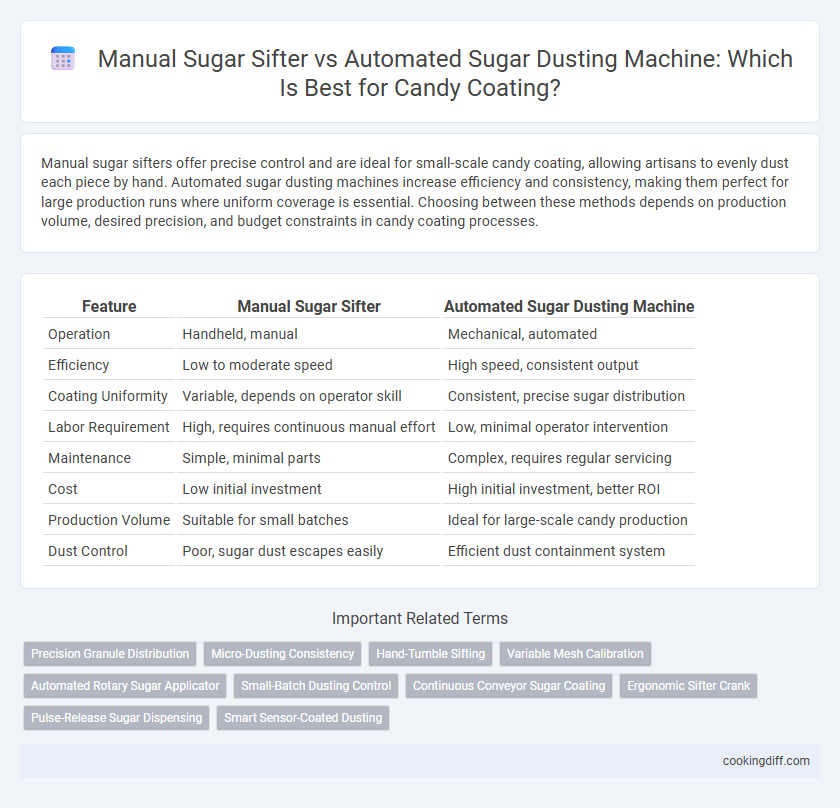

Table of Comparison

| Feature | Manual Sugar Sifter | Automated Sugar Dusting Machine |

|---|---|---|

| Operation | Handheld, manual | Mechanical, automated |

| Efficiency | Low to moderate speed | High speed, consistent output |

| Coating Uniformity | Variable, depends on operator skill | Consistent, precise sugar distribution |

| Labor Requirement | High, requires continuous manual effort | Low, minimal operator intervention |

| Maintenance | Simple, minimal parts | Complex, requires regular servicing |

| Cost | Low initial investment | High initial investment, better ROI |

| Production Volume | Suitable for small batches | Ideal for large-scale candy production |

| Dust Control | Poor, sugar dust escapes easily | Efficient dust containment system |

Introduction to Candy Coating Techniques

| Manual Sugar Sifter | Offers precise control over sugar distribution, ideal for small batches and artisanal candy coating. |

| Automated Sugar Dusting Machine | Enhances efficiency and uniformity in large-scale production, ensuring consistent candy coating with minimal labor. |

| Candy Coating Techniques | Involve applying fine sugar layers either manually or with machines, impacting texture, appearance, and taste of candies. |

What is a Manual Sugar Sifter?

A manual sugar sifter is a hand-operated tool used for evenly coating candies with powdered sugar. It allows precise control over the amount and distribution of sugar dust during the candying process.

- Handheld Operation - Requires physical effort to shake or turn a crank, distributing sugar manually.

- Simple Design - Features a fine mesh screen to break up clumps and create a consistent sugar dust.

- Cost-Effective - Low initial investment and maintenance compared to automated machines.

Understanding Automated Sugar Dusting Machines

Automated sugar dusting machines use precise airflow and vibration technology to evenly coat candies with powdered sugar, ensuring consistent quality and reducing waste. These machines can handle high volumes and complex shapes, increasing production efficiency compared to manual sugar sifters. Integration with conveyor systems allows seamless operation in large-scale candy manufacturing processes.

Key Differences Between Manual and Automated Sugar Coating

What are the key differences between manual sugar sifters and automated sugar dusting machines for coating candies? Manual sugar sifters require hands-on operation, providing precise control but limiting efficiency and speed. Automated sugar dusting machines enhance productivity by evenly coating large batches quickly, though they may lack the nuanced control of manual methods.

Efficiency and Speed: Manual vs Automated Dusting

Automated sugar dusting machines significantly increase coating speed and uniformity compared to manual sifters, enhancing production efficiency. Manual sifters require more labor and time, leading to inconsistent sugar distribution on candies.

- Faster Processing Speed - Automated machines coat large batches of candies quickly, reducing production time.

- Consistent Sugar Application - Automated dusting ensures an even layer of sugar, improving product quality.

- Labor Efficiency - Manual sifters demand continuous operator attention, whereas machines decrease labor costs and fatigue.

Consistency of Coating: Precision in Results

Manual sugar sifters often produce uneven coatings due to variable hand speed and pressure, impacting the candy's texture and appearance. Automated sugar dusting machines deliver precise, consistent sugar distribution, ensuring uniformity and enhanced visual appeal across large batches.

- Manual Sifter Variability - Operator-dependent pressure causes inconsistent sugar layering on candy surfaces.

- Automated Precision - Machines use calibrated nozzles to distribute sugar evenly, reducing waste and rework.

- Batch Uniformity - Automated dusting guarantees each candy piece receives identical coating thickness, vital for quality control.

Consistent coating achieved by automated sugar dusting significantly improves overall candy quality and consumer satisfaction.

Maintenance and Cleaning: Manual vs Machine

Manual sugar sifters require minimal maintenance and are easy to clean due to their simple design, making them ideal for small-scale candy coating. Automated sugar dusting machines demand regular maintenance to ensure optimal performance, including lubrication and filter replacement, which can increase downtime. Cleaning automated machines is more complex and time-consuming, often involving disassembly to prevent sugar buildup and maintain hygiene standards.

Cost Analysis: Investment and Operational Expenses

Manual sugar sifters require minimal initial investment, often costing under $100, making them ideal for small-scale candy production with low operational expenses limited to labor and occasional maintenance. Automated sugar dusting machines, however, demand a substantial upfront investment ranging from $5,000 to $20,000, reflecting advanced technology and increased production capacity.

Operational costs for automated machines include electricity, regular technical maintenance, and skilled operators, which can increase long-term expenses but improve efficiency and consistency in coating candies. Manual sifters rely heavily on manual labor, resulting in higher time costs and potential inconsistencies in sugar distribution. Businesses must weigh initial outlay and ongoing expenses against production volume and quality to select the best sugar coating method.

Suitability for Home and Commercial Candy Makers

Manual sugar sifters offer precise control and flexibility, making them ideal for home candy makers who produce small batches and prefer hands-on techniques. Their affordability and ease of use suit hobbyists seeking detailed sugar coating without investing in costly equipment.

Automated sugar dusting machines provide consistent and rapid coating, benefiting commercial candy producers aiming to optimize large-scale production and maintain uniform quality. These machines enhance efficiency and reduce labor costs, proving essential for high-volume candy manufacturing operations.

Related Important Terms

Precision Granule Distribution

Manual sugar sifters rely on operator skill for granule distribution, often resulting in inconsistent coating thickness and uneven candy appearance. Automated sugar dusting machines utilize precise calibration and controlled airflow to ensure uniform granule distribution, enhancing coating consistency and product quality in candy manufacturing.

Micro-Dusting Consistency

Manual sugar sifters offer limited micro-dusting consistency due to uneven hand movements and variable pressure, often resulting in patchy candy coatings. Automated sugar dusting machines ensure uniform micro-dusting with precise control over sugar flow and distribution, enhancing coating quality and reducing material waste in candy production.

Hand-Tumble Sifting

Hand-tumble sifting offers precise control over sugar distribution, enhancing the texture and appearance of candies by allowing artisans to manually adjust the coating thickness. This traditional method, while labor-intensive, ensures uniform sugar crystals and avoids over-dusting, which is often a challenge with automated sugar dusting machines.

Variable Mesh Calibration

Manual sugar sifters offer variable mesh calibration by allowing operators to adjust sieve sizes for precise sugar particle distribution, ideal for small-scale or artisanal candy coating. Automated sugar dusting machines feature programmable mesh calibration systems that enable consistent and rapid adjustment of sugar granule sizes, increasing efficiency and uniformity in large-scale candy production.

Automated Rotary Sugar Applicator

Automated rotary sugar applicators deliver precise, consistent coating thickness on candies, significantly increasing production efficiency compared to manual sugar sifters. These machines optimize sugar usage by evenly distributing fine sugar particles, reducing waste and ensuring uniform candy appearance.

Small-Batch Dusting Control

Manual sugar sifters offer precise control over dusting small batches of candies, enabling careful adjustment of sugar distribution for delicate coatings. Automated sugar dusting machines increase efficiency but may lack the nuanced control necessary for uniform coverage in artisanal or limited production runs.

Continuous Conveyor Sugar Coating

Continuous conveyor sugar coating enhances efficiency and consistency when applying sugar to candies, with automated sugar dusting machines offering precise control over sugar distribution and reducing labor compared to manual sugar sifters. Automated systems optimize sugar usage and increase production speed while ensuring uniform coating, essential for large-scale candy manufacturing.

Ergonomic Sifter Crank

The manual sugar sifter features an ergonomic sifter crank designed to reduce hand fatigue and improve grip during prolonged use, enhancing precision in coating candies with sugar. Automated sugar dusting machines eliminate manual effort entirely, but the ergonomic design of the sifter crank in manual sifters remains critical for small-scale or artisanal candy production where control and comfort are paramount.

Pulse-Release Sugar Dispensing

Manual sugar sifters rely on consistent hand pressure to release sugar, resulting in uneven distribution that can affect the uniformity of candy coatings. Automated sugar dusting machines with pulse-release sugar dispensing technology provide precise, controlled bursts of sugar, ensuring consistent coverage and enhanced product quality in candy coating processes.

Manual Sugar Sifter vs Automated Sugar Dusting Machine for coating candies. Infographic

cookingdiff.com

cookingdiff.com