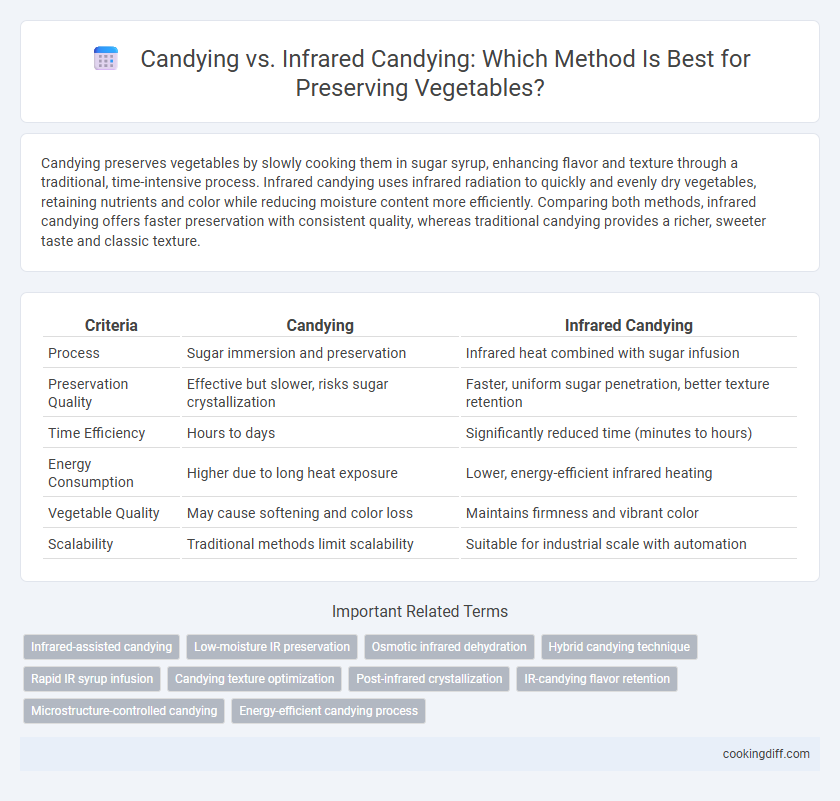

Candying preserves vegetables by slowly cooking them in sugar syrup, enhancing flavor and texture through a traditional, time-intensive process. Infrared candying uses infrared radiation to quickly and evenly dry vegetables, retaining nutrients and color while reducing moisture content more efficiently. Comparing both methods, infrared candying offers faster preservation with consistent quality, whereas traditional candying provides a richer, sweeter taste and classic texture.

Table of Comparison

| Criteria | Candying | Infrared Candying |

|---|---|---|

| Process | Sugar immersion and preservation | Infrared heat combined with sugar infusion |

| Preservation Quality | Effective but slower, risks sugar crystallization | Faster, uniform sugar penetration, better texture retention |

| Time Efficiency | Hours to days | Significantly reduced time (minutes to hours) |

| Energy Consumption | Higher due to long heat exposure | Lower, energy-efficient infrared heating |

| Vegetable Quality | May cause softening and color loss | Maintains firmness and vibrant color |

| Scalability | Traditional methods limit scalability | Suitable for industrial scale with automation |

Introduction to Vegetable Candying

Vegetable candying is a traditional preservation method that involves soaking vegetables in sugar syrup to enhance flavor and extend shelf life. Infrared candying uses infrared heat to accelerate the dehydration process, improving efficiency and texture retention.

- Vegetable Candying - Soaks vegetables in concentrated sugar solutions to prevent microbial growth and maintain sweetness.

- Infrared Candying - Utilizes infrared radiation to speed up drying while preserving nutrients and color better than conventional methods.

- Comparison - Infrared candying reduces processing time and energy consumption compared to traditional candying, offering a modern approach to vegetable preservation.

Traditional Candying: Process and Techniques

What distinguishes traditional candying methods from infrared candying in vegetable preservation? Traditional candying involves soaking vegetables in progressively concentrated sugar syrups to replace water content, enhancing shelf life and flavor. This process relies heavily on careful timing and temperature control to achieve the desired texture and sweetness.

What is Infrared Candying?

Infrared candying is an advanced technique for preserving vegetables by using infrared radiation to infuse sugar more efficiently. This method accelerates the candying process while maintaining better texture and color compared to traditional candying.

- Infrared radiation - penetrates vegetable tissues quickly, enabling uniform sugar absorption.

- Energy efficiency - reduces processing time and lowers energy consumption compared to conventional heat methods.

- Quality retention - preserves the natural appearance, moisture, and flavor of candied vegetables more effectively.

Key Differences Between Traditional and Infrared Candying

| Aspect | Traditional Candying | Infrared Candying |

|---|---|---|

| Process Duration | Longer, typically several hours to days | Shorter, often reduced by 30-50% |

| Energy Efficiency | Lower, relies on conventional heating methods | Higher, uses targeted infrared radiation reducing energy waste |

| Preservation Quality | Effective sugar penetration but potential nutrient loss | Better retention of nutrients and color due to rapid heating |

| Texture and Taste | May result in softer texture and caramelized flavor | Maintains firmer texture and natural vegetable flavor |

| Equipment Requirements | Simple, uses traditional heating or boiling setups | Requires specialized infrared ovens or lamps |

Flavor and Texture Comparison

Candying preserves vegetables by slowly infusing them with sugar, resulting in a rich, sweet flavor and a tender, yet slightly firm texture. Infrared candying uses radiant heat to enhance sugar penetration, producing a more intense flavor and a crisper texture compared to traditional methods. The infrared process also reduces moisture loss, maintaining the vegetable's natural freshness alongside its sweetness.

Nutritional Impacts of Both Methods

Candying preserves vegetables by soaking them in sugar syrup, which can lead to nutrient loss, particularly in heat-sensitive vitamins like vitamin C. Infrared candying uses infrared radiation to penetrate the vegetable quicker, reducing exposure time and better retaining nutrients such as antioxidants and water-soluble vitamins. Studies show infrared candying maintains higher levels of essential nutrients compared to traditional candying methods, improving the nutritional quality of preserved vegetables.

Efficiency and Time Considerations

Candying preserves vegetables by infusing them with sugar, which can be time-consuming, often requiring several hours to achieve optimal texture and flavor. Infrared candying accelerates this process by using infrared radiation to evenly heat the vegetables, significantly reducing preservation time.

Infrared candying enhances efficiency through rapid heat penetration, minimizing sugar crystallization and moisture loss compared to traditional candying methods. This technology allows for faster production cycles while maintaining the vegetables' nutritional value and sensory qualities.

Equipment and Cost Analysis

Candying vegetables traditionally requires specialized candying kettles and vacuum chambers, which involve moderate initial investment and operating costs. Infrared candying utilizes advanced infrared heating systems, often integrated with conveyor belts, increasing equipment costs but improving energy efficiency.

Traditional candying equipment tends to have higher maintenance expenses due to prolonged heating cycles and manual controls. Infrared candying machinery demands a higher upfront capital but reduces energy consumption and shortens processing times, lowering long-term operational costs.

Shelf Life and Storage Benefits

Candying preserves vegetables by soaking them in sugar solutions, extending shelf life through moisture reduction and sugar's antimicrobial properties. Infrared candying enhances this process by using infrared radiation to accelerate sugar penetration and drying, resulting in improved preservation and longer shelf stability.

Vegetables treated with infrared candying typically exhibit a longer shelf life compared to traditional candying due to more uniform drying and reduced microbial growth. The infrared method allows for better retention of texture and color during storage, maintaining quality over extended periods. This technique also reduces storage space requirements by producing lighter, less moist products less prone to spoilage.

Related Important Terms

Infrared-assisted candying

Infrared-assisted candying enhances moisture removal and preserves the color and texture of vegetables more efficiently than traditional candying methods by using infrared radiation to penetrate the vegetable surface quickly. This technology accelerates drying time and improves flavor retention, resulting in higher-quality preserved vegetables with extended shelf life.

Low-moisture IR preservation

Low-moisture infrared candying enhances vegetable preservation by rapidly removing moisture while retaining natural flavors and nutrients, outperforming traditional candying methods that often lead to higher moisture content and reduced shelf life. Infrared candying's precise heat application minimizes microbial growth and enzymatic activity, ensuring longer-lasting, high-quality preserved vegetables.

Osmotic infrared dehydration

Osmotic infrared dehydration combines traditional candying with infrared technology to enhance moisture removal while retaining vegetable texture and nutritional value. This method accelerates water loss through controlled osmotic pressure and infrared heat, resulting in superior preservation compared to conventional candying techniques.

Hybrid candying technique

Hybrid candying technique combines traditional candying methods with infrared heat to enhance preservation efficiency, reducing drying time while maintaining vegetable texture and flavor. This approach optimizes moisture removal and nutrient retention, offering a superior alternative to conventional candying and solely infrared-based processes.

Rapid IR syrup infusion

Rapid IR syrup infusion in infrared candying significantly accelerates the preservation process by enabling deeper and faster penetration of sugar syrup into vegetables compared to traditional candying. This technology enhances flavor retention and texture quality while reducing processing time and energy consumption.

Candying texture optimization

Candying preserves vegetables by soaking them in sugar syrup, creating a firm yet tender texture that enhances bite consistency and moisture retention. Infrared candying uses targeted heat to optimize sugar crystallization, resulting in a crispier exterior and more uniform texture without compromising the vegetable's natural firmness.

Post-infrared crystallization

Post-infrared crystallization enhances the candying process by enabling faster sugar crystallization on vegetable surfaces, improving texture and shelf life compared to traditional candying methods. Infrared candying reduces moisture retention more efficiently, resulting in a firmer product with extended preservation qualities.

IR-candying flavor retention

Infrared candying preserves vegetables by using infrared radiation to penetrate and uniformly heat, resulting in better retention of natural flavors and nutrients compared to traditional candying methods that rely on prolonged boiling and sugar infusion. The precise control of temperature and reduced water exposure in IR-candying minimizes flavor loss and maintains the vegetable's original taste profile more effectively.

Microstructure-controlled candying

Microstructure-controlled candying enhances vegetable preservation by precisely regulating sugar diffusion and moisture content, resulting in superior texture retention compared to traditional candying. Infrared candying accelerates drying and sugar penetration through targeted thermal energy, maintaining cellular integrity and minimizing structural damage during preservation.

Candying vs Infrared Candying for preserving vegetables. Infographic

cookingdiff.com

cookingdiff.com