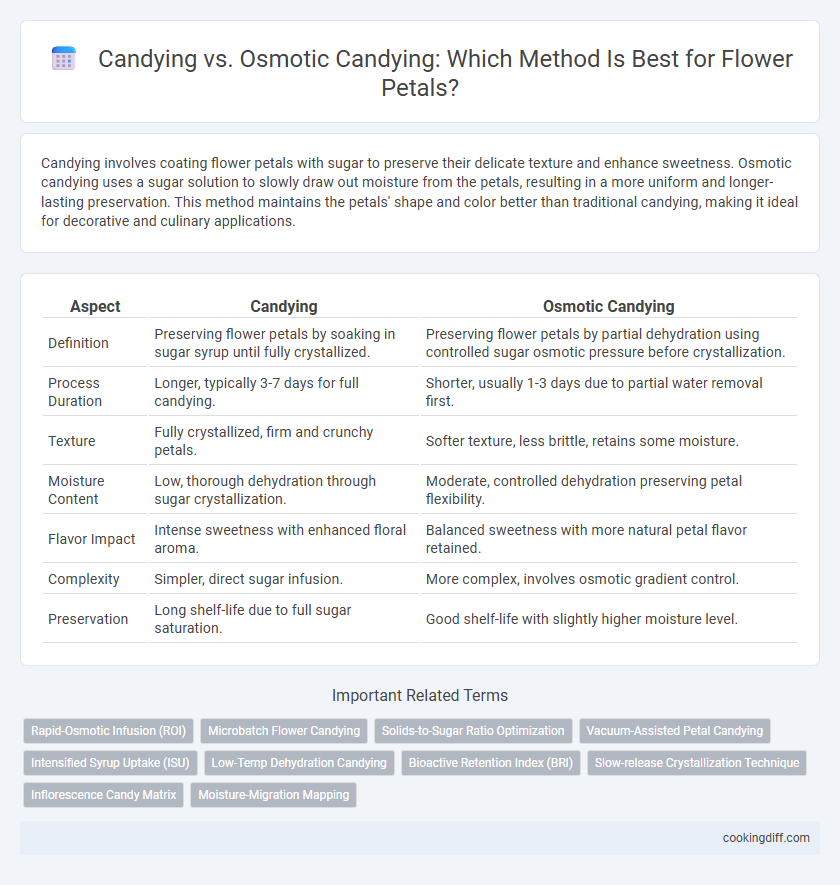

Candying involves coating flower petals with sugar to preserve their delicate texture and enhance sweetness. Osmotic candying uses a sugar solution to slowly draw out moisture from the petals, resulting in a more uniform and longer-lasting preservation. This method maintains the petals' shape and color better than traditional candying, making it ideal for decorative and culinary applications.

Table of Comparison

| Aspect | Candying | Osmotic Candying |

|---|---|---|

| Definition | Preserving flower petals by soaking in sugar syrup until fully crystallized. | Preserving flower petals by partial dehydration using controlled sugar osmotic pressure before crystallization. |

| Process Duration | Longer, typically 3-7 days for full candying. | Shorter, usually 1-3 days due to partial water removal first. |

| Texture | Fully crystallized, firm and crunchy petals. | Softer texture, less brittle, retains some moisture. |

| Moisture Content | Low, thorough dehydration through sugar crystallization. | Moderate, controlled dehydration preserving petal flexibility. |

| Flavor Impact | Intense sweetness with enhanced floral aroma. | Balanced sweetness with more natural petal flavor retained. |

| Complexity | Simpler, direct sugar infusion. | More complex, involves osmotic gradient control. |

| Preservation | Long shelf-life due to full sugar saturation. | Good shelf-life with slightly higher moisture level. |

Introduction to Candying Flower Petals

Candying flower petals preserves their delicate texture and vibrant colors by coating them in sugar, creating a sweet, translucent finish. Unlike osmotic candying, which relies on a sugar solution to draw out moisture gradually, traditional candying involves brushing or dipping petals directly in syrup or sugar crystals for immediate crystallization. This method enhances the visual appeal and flavor of edible flowers, making them ideal for decorative culinary uses.

What is Traditional Candying?

Traditional candying involves immersing flower petals in a hot sugar syrup to preserve and enhance their natural color and flavor. This process creates a glossy, crystallized coating that protects the delicate petals from moisture and decay. Unlike osmotic candying, traditional candying relies on direct heat and sugar saturation for preservation rather than gradual water removal through osmosis.

The Science Behind Osmotic Candying

Osmotic candying preserves flower petals by using a concentrated sugar solution that draws out moisture through osmosis, preventing microbial growth while maintaining delicate textures. This method differs from traditional candying by focusing on moisture equilibrium rather than simple sugar coating, enhancing flavor penetration and structural integrity.

- Osmosis - Sugar solution creates a hypertonic environment that extracts water from petals.

- Microbial Inhibition - Reduced water activity lowers the risk of spoilage and decay.

- Texture Retention - Controlled dehydration preserves petal softness and appearance.

Osmotic candying combines science and art to extend shelf life while enhancing the sensory qualities of flower petals.

Key Differences: Candying vs Osmotic Candying

| Aspect | Candying | Osmotic Candying |

|---|---|---|

| Process | Flower petals are coated and preserved by soaking in a sugar syrup followed by drying, creating a crystallized sugar layer on the surface. | Flower petals undergo partial dehydration through osmotic pressure by immersion in a high-concentration sugar solution, which draws out moisture internally before drying. |

| Texture Outcome | Results in a firm, crunchy exterior with a tender interior, maintaining petal shape and color vividly. | Produces a more pliable texture with moisture evenly reduced, enhancing shelf life while keeping petals supple. |

| Preservation Method | Relies primarily on surface sugar crystallization for preservation. | Utilizes osmotic dehydration to reduce water activity inside petals, delaying microbial growth. |

Sugar Solutions and Concentrations for Each Method

How do sugar solutions and concentrations differ between candying and osmotic candying for flower petals? Candying typically uses a saturated sugar syrup, around 70-80% concentration, to coat the petals and crystallize sugar on the surface. Osmotic candying employs a lower concentration sugar solution, approximately 40-60%, allowing gradual sugar infusion and dehydration for enhanced texture and preservation.

Texture and Flavor Outcomes Compared

Candying flower petals results in a crisp, slightly brittle texture with a concentrated floral sweetness, while osmotic candying produces a softer, more pliable petal with a balanced flavor infusion. Both methods enhance the natural aroma and taste, but osmotic candying tends to retain a more delicate and nuanced flavor profile.

- Candying Texture - Creates a firm, crunchy surface that preserves shape and enhances a sweet, crystallized feel.

- Osmotic Texture - Yields a tender, flexible petal that remains moist and less brittle for a natural mouthfeel.

- Flavor Outcomes - Candying amplifies a sugary flavor, while osmotic candying integrates subtle floral notes more evenly.

Color Retention in Petal Candying Techniques

Candying flower petals preserves their delicate colors, but osmotic candying offers superior color retention by slowly replacing water content with sugar. The osmotic process minimizes petal discoloration and enhances vibrancy compared to traditional candying methods.

- Traditional Candying - Uses direct sugar coating, which may cause some color fading due to rapid moisture loss.

- Osmotic Candying - Gradually infuses sugar through osmotic pressure, preserving petal pigments more effectively.

- Color Retention Efficiency - Osmotic candying maintains brighter, more vivid petal hues over extended periods.

Step-by-Step Guide: Traditional Candying Process

Traditional candying of flower petals involves coating the petals with a sugar syrup and allowing them to dry slowly, preserving their delicate texture and vibrant colors. This method requires careful brushing of the syrup onto each petal followed by air drying in a low-humidity environment to achieve a crisp finish.

The petals are typically dipped or brushed multiple times with the sugar solution, gradually building a thin, even layer that enhances both flavor and appearance. Drying times vary but generally take several hours to ensure the sugar crystallizes perfectly without causing the petals to become soggy or brittle.

Step-by-Step Guide: Osmotic Candying Process

The osmotic candying process for flower petals involves submerging the petals in a sugar syrup solution, allowing the sugar to gradually penetrate and preserve the petals' shape and color. This method differs from traditional candying by using osmosis to draw out moisture while infusing sweetness.

Start by preparing a concentrated sugar syrup, usually with a 2:1 sugar-to-water ratio, heated until the sugar dissolves completely. Slowly immerse the flower petals in the syrup for several days, changing the syrup periodically to maintain concentration and achieve optimal candying results.

Related Important Terms

Rapid-Osmotic Infusion (ROI)

Rapid-Osmotic Infusion (ROI) enhances traditional candying by accelerating the osmotic candying process for flower petals, ensuring quicker and more uniform sugar penetration compared to conventional methods. This technique optimizes moisture removal and syrup absorption rates, resulting in petals with superior texture and longer shelf life.

Microbatch Flower Candying

Microbatch flower candying offers precise control over the infusion of sugar into delicate petals, preserving their natural texture and vibrant color more effectively than traditional osmotic candying methods. This technique enhances flavor concentration and shelf life by optimizing sugar absorption at the microstructural level, ensuring superior quality and aesthetic appeal in candied flower petals.

Solids-to-Sugar Ratio Optimization

Optimizing the solids-to-sugar ratio in candying flower petals enhances texture and flavor, where candying typically uses a higher sugar concentration for preservation, while osmotic candying allows controlled infusion with a balanced sugar solution to maintain petal integrity. Adjusting this ratio precisely ensures maximum sugar absorption without compromising the delicate structure and natural color of the petals.

Vacuum-Assisted Petal Candying

Vacuum-assisted petal candying accelerates the infusion of sugar syrup into flower petals by reducing pressure, enhancing flavor retention and texture without over-saturation. Compared to traditional osmotic candying, this method shortens processing time while preserving the delicate structure and vibrant colors of the petals.

Intensified Syrup Uptake (ISU)

Candying flower petals involves soaking them in a sugar solution to preserve and enhance their texture and flavor, whereas osmotic candying specifically utilizes a controlled concentration gradient to promote Intensified Syrup Uptake (ISU), resulting in more efficient sugar infusion and longer-lasting preservation. ISU in osmotic candying accelerates moisture removal while increasing sugar penetration, achieving a balanced sweetness and improved petal firmness compared to traditional candying methods.

Low-Temp Dehydration Candying

Low-temp dehydration candying preserves flower petals by gently removing moisture through controlled low-temperature drying, maintaining their delicate texture and vibrant color. Unlike osmotic candying, which relies on sugar solution immersion, this method minimizes sugar absorption, resulting in a naturally crisp and visually appealing petal ideal for edible decorations.

Bioactive Retention Index (BRI)

Candying preserves flower petals by coating them with sugar, resulting in moderate Bioactive Retention Index (BRI) values due to partial nutrient leaching. Osmotic candying enhances BRI significantly by using osmotic pressure to maintain higher levels of antioxidants and phenolics in the petals during processing.

Slow-release Crystallization Technique

Slow-release crystallization technique in candying flower petals ensures gradual sugar infusion, preserving delicate textures and enhancing flavor depth compared to osmotic candying, which relies on faster dehydration through concentrated sugar solutions. This method minimizes petal brittleness and maintains vibrant colors by controlling sugar uptake over extended periods.

Inflorescence Candy Matrix

The Inflorescence Candy Matrix enhances candying by preserving the delicate structure and color vibrancy of flower petals through precise sugar crystallization, unlike osmotic candying which relies on sugar infusion that may cause petal swelling and texture loss. This matrix optimizes moisture control and sugar distribution, ensuring a balanced sweetness that maintains petal integrity and visual appeal.

Candying vs Osmotic Candying for flower petals. Infographic

cookingdiff.com

cookingdiff.com