A sugar thermometer is essential for candying as it accurately measures the liquid's temperature, ensuring precise caramelization and preventing burning. Infrared thermometers, while useful for surface temperature readings, lack the ability to gauge the internal temperature of hot sugar mixtures, making them less reliable for candying. For perfect candy texture and safety, a reliable sugar thermometer remains the best choice.

Table of Comparison

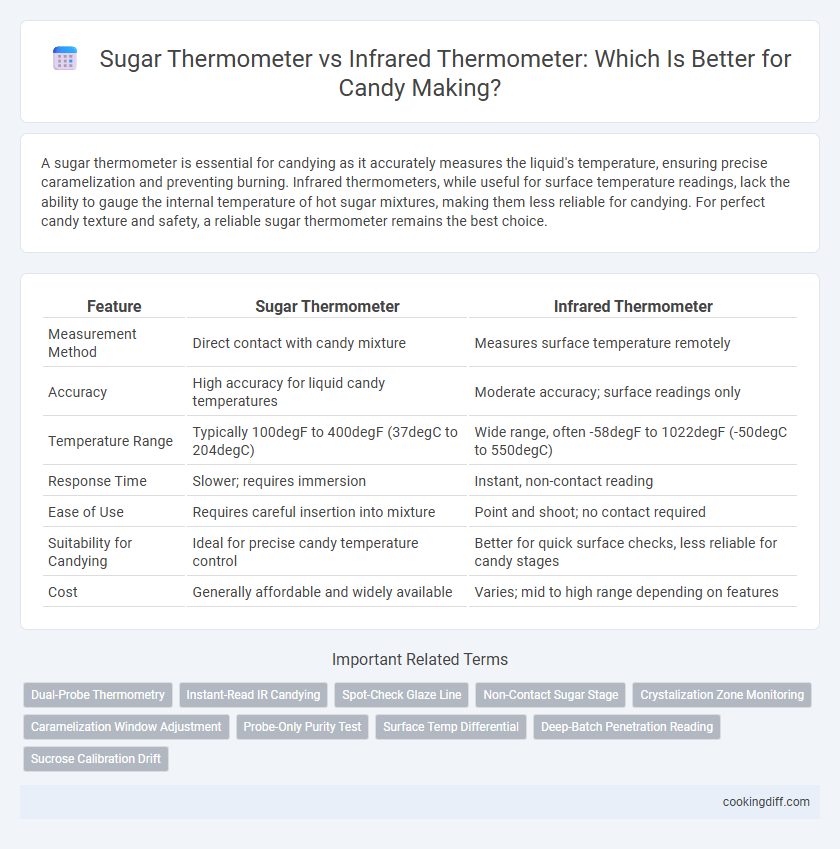

| Feature | Sugar Thermometer | Infrared Thermometer |

|---|---|---|

| Measurement Method | Direct contact with candy mixture | Measures surface temperature remotely |

| Accuracy | High accuracy for liquid candy temperatures | Moderate accuracy; surface readings only |

| Temperature Range | Typically 100degF to 400degF (37degC to 204degC) | Wide range, often -58degF to 1022degF (-50degC to 550degC) |

| Response Time | Slower; requires immersion | Instant, non-contact reading |

| Ease of Use | Requires careful insertion into mixture | Point and shoot; no contact required |

| Suitability for Candying | Ideal for precise candy temperature control | Better for quick surface checks, less reliable for candy stages |

| Cost | Generally affordable and widely available | Varies; mid to high range depending on features |

Introduction to Candying: Precision Matters

Accurate temperature measurement is crucial in candying to achieve the perfect texture and consistency. Choosing between a sugar thermometer and an infrared thermometer impacts the precision and outcome of the candying process.

- Sugar Thermometer - Measures internal temperature of the sugar mixture for precise control during cooking.

- Infrared Thermometer - Reads surface temperature instantly without contact, useful for quick checks but less accurate for candying.

- Precision Matters - Consistent temperature monitoring ensures proper crystallization and prevents burning or undercooking.

Sugar Thermometer: Traditional Tool for Candy Making

The sugar thermometer is a traditional tool for candy making, offering precise temperature readings necessary for achieving perfect candy textures. It measures the actual temperature of the sugar syrup by direct contact, ensuring accuracy in monitoring critical stages like soft ball and hard crack.

This thermometer typically features a long metal probe and a clear dial, allowing candy makers to easily observe temperature changes during cooking. Unlike infrared thermometers, it provides consistent readings despite steam or sugar crystals on the pan surface. Its reliability and simplicity make it an essential instrument for recipes requiring meticulous temperature control.

Infrared Thermometer: Modern Technology in the Kitchen

Infrared thermometers offer rapid, non-contact temperature readings, making them ideal for monitoring candy's surface heat without contamination. Their precision in measuring hot sugar mixtures enhances safety and efficiency during the candying process.

Unlike traditional sugar thermometers, infrared models reduce the risk of crystal formation by avoiding direct immersion in the syrup. This modern technology streamlines candy preparation, ensuring consistent texture and flavor every time.

Accuracy Comparison: Sugar vs Infrared Thermometers

Sugar thermometers provide precise, consistent temperature readings essential for candying, typically within +-1degF accuracy. Infrared thermometers, while faster and non-contact, often struggle with reflective surfaces and uneven heat distribution, leading to less reliable readings.

The direct contact method of sugar thermometers measures the actual temperature of the boiling sugar mixture, ensuring optimal caramelization and texture. Infrared devices are better suited for surface temperature checks but cannot replace the accuracy required for intricate candying processes.

Ease of Use: Handling and Practicality

Sugar thermometers provide precise temperature readings essential for candying but require immersion in the hot syrup, making them less convenient to handle. Infrared thermometers offer quick, contactless temperature checks from a distance, enhancing safety and speed during candy-making processes.

- Immersion Requirement - Sugar thermometers need to be submerged for accurate readings, increasing handling complexity and risk of burns.

- Contactless Measurement - Infrared thermometers measure temperature without touching the candy, improving ease of use and hygiene.

- Temperature Accuracy - Sugar thermometers deliver consistent, direct temperature data critical for precise candy consistency.

Choosing between the two depends on balancing ease of handling with required accuracy during candying.

Response Time: Real-Time Temperature Readings

The sugar thermometer provides continuous, real-time temperature readings essential for precise candying stages. Infrared thermometers offer rapid surface temperature checks but may lack consistent real-time data accuracy during the cooking process.

- Sugar Thermometer Response Time - Offers immediate, continuous feedback critical for monitoring boiling sugar temperatures between 230degF and 320degF.

- Infrared Thermometer Speed - Delivers instant surface temperature readings without contact, useful for quick checks but less reliable for dynamic temperature changes.

- Real-Time Accuracy - Sugar thermometers capture ongoing temperature fluctuations essential for candy consistency, unlike infrared models that can miss internal temperature variations.

Cleaning and Maintenance: Hygiene Factors

| Device | Cleaning Ease | Hygiene Maintenance |

| Sugar Thermometer | Requires direct contact with hot sugar, necessitating thorough cleaning to remove sticky residues that can harbor bacteria. | Regular sanitization with warm soapy water prevents contamination; careful drying is essential to avoid corrosion and maintain accuracy. |

| Infrared Thermometer | Non-contact measurement simplifies cleaning as no syrup residue accumulates on the device. | Minimal maintenance reduces cross-contamination risk; wiping the lens with a soft cloth ensures hygienic use and sustained sensor accuracy. |

Safety Considerations in Candy Making

Using a sugar thermometer in candying ensures precise temperature readings directly from the boiling sugar mixture, minimizing risks of burns and undercooked candy. Infrared thermometers offer a non-contact method but can be less accurate due to surface temperature variations, potentially leading to unsafe cooking results. Prioritizing a reliable sugar thermometer enhances safety by reducing the chance of hot sugar splashes and ensures proper candy texture development.

Costs and Accessibility: Which is More Affordable?

Which thermometer is more affordable for candying: sugar thermometer or infrared thermometer? Sugar thermometers are generally less expensive, typically ranging from $10 to $30, making them accessible for most home candy makers. Infrared thermometers, while pricier at $30 to $100, offer quick temperature readings but may not justify the higher cost for occasional candying use.

Related Important Terms

Dual-Probe Thermometry

Dual-probe thermometry combines a traditional sugar thermometer with an infrared thermometer to provide precise temperature readings essential for candying. This method ensures accurate monitoring of both the sugar solution's temperature and surface heat, improving consistency and preventing crystallization.

Instant-Read IR Candying

An infrared thermometer provides instant-read temperature measurements, enabling precise monitoring of sugar stages during candying without direct contact, which reduces contamination risk and saves time compared to traditional sugar thermometers that require immersion and stabilization. This instant-read IR candying method enhances accuracy and efficiency, crucial for achieving perfect candy texture and preventing crystallization.

Spot-Check Glaze Line

A sugar thermometer provides precise, continuous temperature readings essential for accurately reaching the critical glaze line in candying, ensuring perfect sugar crystallization. Infrared thermometers offer quick spot-check measurements but may miss subtle temperature fluctuations vital for consistent glazing results.

Non-Contact Sugar Stage

Infrared thermometers provide accurate non-contact temperature readings essential for monitoring the precise sugar stages in candying without contaminating the mixture. Unlike traditional sugar thermometers that require immersion, infrared devices measure surface temperature swiftly, improving safety and efficiency in candy-making processes.

Crystalization Zone Monitoring

A sugar thermometer measures the temperature directly within the sugar syrup, providing precise data critical for monitoring the crystallization zone between 230degF and 320degF. Infrared thermometers, while quick and non-contact, often give surface temperatures that may not accurately reflect the internal temperature needed to control sugar crystallization in candying.

Caramelization Window Adjustment

Sugar thermometers provide precise temperature readings directly in the syrup, enabling accurate control of the caramelization window essential for candying, whereas infrared thermometers measure surface temperature only, potentially missing critical internal caramelization stages. Adjusting the caramelization window effectively requires the reliable immersion data from a sugar thermometer to prevent overheating or undercooking, ensuring optimal texture and flavor development in candies.

Probe-Only Purity Test

Sugar thermometers with probes provide precise temperature readings directly within the candy mixture, ensuring accurate monitoring of sugar concentration during the candying process. Infrared thermometers, lacking direct contact, may yield less reliable results for probe-only purity tests, as they measure surface temperature rather than the internal sugar solution's consistency.

Surface Temp Differential

Sugar thermometers measure the temperature by direct contact with the syrup, providing precise readings essential for achieving the correct candying stage, while infrared thermometers detect surface temperature without contact, often showing lower readings due to surface cooling effects. The surface temperature differential between the syrup and the thermometer sensor impacts accuracy, making traditional sugar thermometers more reliable for consistent candying results.

Deep-Batch Penetration Reading

A sugar thermometer provides deep-batch penetration readings essential for accurately measuring the internal temperature of thick candy mixtures, ensuring precise sugar stage identification. Infrared thermometers measure surface temperatures only, making them less reliable for deep-batch candying where internal heat control is crucial.

Sugar Thermometer vs Infrared Thermometer for candying. Infographic

cookingdiff.com

cookingdiff.com