A confectionery cooling grid allows air to circulate underneath the candy, ensuring even cooling and preventing sticky bottoms, unlike a regular baking sheet that traps moisture and can cause candy to become soggy. Using a cooling grid also helps maintain the candy's shape and texture by promoting faster, more uniform setting. For precise candy setting, a cooling grid is essential to achieve professional-quality results.

Table of Comparison

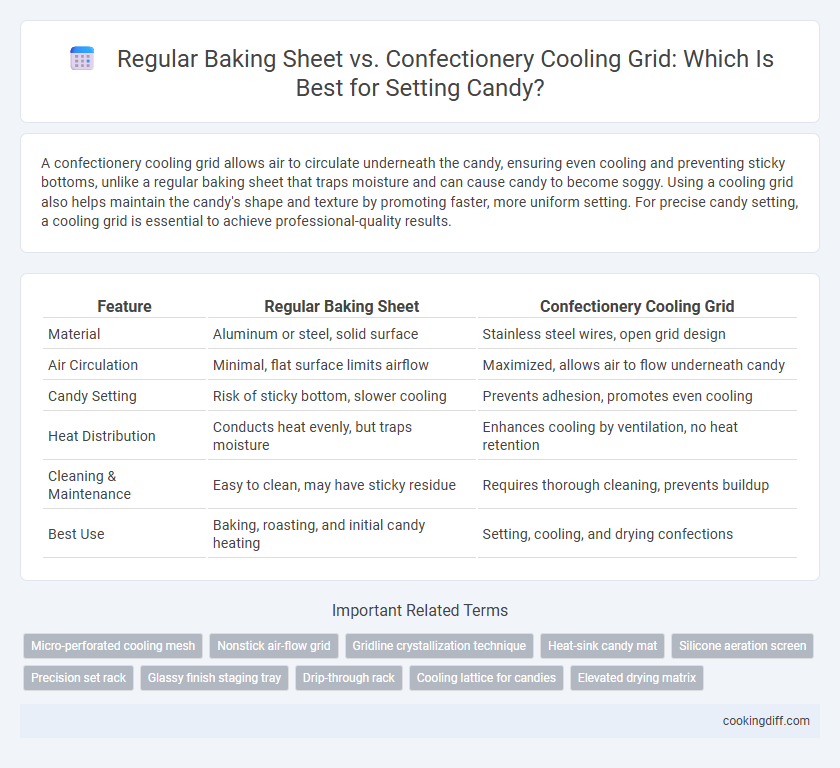

| Feature | Regular Baking Sheet | Confectionery Cooling Grid |

|---|---|---|

| Material | Aluminum or steel, solid surface | Stainless steel wires, open grid design |

| Air Circulation | Minimal, flat surface limits airflow | Maximized, allows air to flow underneath candy |

| Candy Setting | Risk of sticky bottom, slower cooling | Prevents adhesion, promotes even cooling |

| Heat Distribution | Conducts heat evenly, but traps moisture | Enhances cooling by ventilation, no heat retention |

| Cleaning & Maintenance | Easy to clean, may have sticky residue | Requires thorough cleaning, prevents buildup |

| Best Use | Baking, roasting, and initial candy heating | Setting, cooling, and drying confections |

Understanding the Basics: Baking Sheets vs Cooling Grids

Choosing between a regular baking sheet and a confectionery cooling grid significantly impacts the texture and finish when setting candy. Baking sheets provide a solid surface ideal for even heat distribution, while cooling grids allow air circulation to prevent moisture buildup and promote quicker cooling.

- Regular Baking Sheet - Offers a flat, heat-conductive surface suitable for spreading candy mixtures evenly during the setting process.

- Confectionery Cooling Grid - Elevates candies to allow airflow underneath, reducing sticky residue and speeding up hardening.

- Material and Design Differences - Baking sheets are often made of metal with a smooth surface, whereas cooling grids feature mesh or wire racks designed specifically for airflow essential in candy setting.

Material Matters: Surface Types for Setting Candy

Regular baking sheets typically feature a smooth aluminum or stainless steel surface that can cause candies to stick, making removal challenging. Confectionery cooling grids, often made of stainless steel with raised wire surfaces, allow air circulation and reduce direct contact, promoting even cooling without sticking. Choosing a material with a non-stick or coated surface significantly improves candy setting by preventing adhesion and maintaining candy shape.

Airflow and Cooling Efficiency Compared

| Aspect | Regular Baking Sheet | Confectionery Cooling Grid |

|---|---|---|

| Airflow | Limited airflow due to solid surface, causing slower heat dissipation and potential moisture retention. | Enhanced airflow with open wire design, promoting faster evaporation and preventing condensation on candy surfaces. |

| Cooling Efficiency | Moderate cooling speed, can lead to uneven candy setting and longer wait times. | Optimized cooling speed ensures consistent candy setting and reduces overall cooling duration. |

Candy Texture: Impact of Baking Sheet vs Cooling Grid

Using a regular baking sheet for setting candy often results in uneven cooling, affecting texture by creating firmer edges and a softer center. In contrast, a confectionery cooling grid promotes uniform air circulation, leading to consistent hardness and a smoother finish.

- Heat Distribution - Baking sheets retain heat longer, causing uneven candy cooling and potential texture variations.

- Air Circulation - Cooling grids allow air to flow beneath the candy, ensuring even setting and crunchiness.

- Moisture Control - Grids reduce moisture buildup under the candy, preventing stickiness and enhancing crisp texture.

Choosing a confectionery cooling grid optimizes candy texture by promoting uniform hardness and a clean finish.

Stickiness and Release: Which Prevents Sticking?

Regular baking sheets often cause sticky candies to adhere due to their flat, non-perforated surfaces, leading to difficult release and potential damage. Confectionery cooling grids, with raised bars and open spaces, allow airflow and minimize contact points, significantly reducing stickiness and promoting easier candy release. The grid's structure effectively prevents sticking by facilitating even cooling and preventing moisture buildup underneath the candy.

Cleaning and Maintenance Differences

Regular baking sheets often require careful cleaning to remove sticky candy residues, which can be challenging and time-consuming. Confectionery cooling grids have an open wire design that allows for easier washing and quicker drying, minimizing residue buildup and maintaining hygiene.

- Non-stick coatings on baking sheets can degrade due to frequent scraping, demanding gentle cleaning methods.

- Confectionery cooling grids' open structure prevents pooling of sugary syrup, reducing sticky mess and simplifying cleaning.

- Cooling grids are dishwasher safe in most cases, while some baking sheets may warp or lose coating when washed in high heat environments.

Suitability for Different Candy Types

Regular baking sheets provide a flat, solid surface ideal for setting soft candies like fudge or caramel, preventing them from sticking or losing shape. They allow even cooling across the candy's surface, which is essential for maintaining texture and appearance.

Confectionery cooling grids offer elevated airflow, making them suitable for hard candies or brittle that require rapid and uniform cooling to prevent moisture buildup. The grid's open design facilitates air circulation around the candy, enhancing the setting process for crisp, dry finishes.

Space and Storage Considerations

Regular baking sheets offer a compact storage solution, fitting easily into most kitchen cabinets due to their flat design. Confectionery cooling grids, while bulkier, require more vertical space to store because of their elevated legs and grid structure.

The open design of cooling grids allows for better air circulation around candies, which is essential for even setting and preventing moisture buildup. However, their larger footprint can make storage challenging in small kitchens where space is limited. Prioritizing one over the other depends on balancing the need for efficient candy cooling with available kitchen storage capacity.

Cost and Accessibility Analysis

Is a regular baking sheet or a confectionery cooling grid more cost-effective for setting candy? Regular baking sheets are typically more affordable and widely available in most kitchens, making them an accessible choice for casual candy makers. Confectionery cooling grids, while more expensive, offer specialized airflow that can improve candy texture and prevent sogginess, justifying the investment for professional or frequent candy production.

Related Important Terms

Micro-perforated cooling mesh

Micro-perforated cooling grids offer superior airflow compared to regular baking sheets, enabling even cooling and reducing moisture buildup essential for candy setting. The fine mesh design prevents sticking and allows delicate candies to harden uniformly without residual heat pockets that can occur on solid surfaces.

Nonstick air-flow grid

A confectionery cooling grid with a nonstick air-flow design enhances candy setting by allowing optimal air circulation, preventing moisture buildup and ensuring even cooling, unlike a regular baking sheet that can trap heat and cause sticky residues. The elevated grid structure reduces contact points, minimizing candy sticking and preserving texture integrity during the curing process.

Gridline crystallization technique

Using a confectionery cooling grid enhances the Gridline crystallization technique by allowing air to circulate evenly around the candy, promoting uniform cooling and preventing moisture buildup that can cause sticky surfaces. In contrast, a regular baking sheet often traps heat and condensation beneath the candy, leading to uneven crystallization and less consistent texture.

Heat-sink candy mat

Heat-sink candy mats offer superior temperature regulation compared to regular baking sheets, preventing hot spots and ensuring even cooling for candy setting. Unlike confectionery cooling grids, these mats provide a stable, non-stick surface that minimizes heat transfer inconsistencies, resulting in smoother, more consistent candy textures.

Silicone aeration screen

A silicone aeration screen on a confectionery cooling grid ensures even air circulation beneath the candy, preventing moisture buildup and promoting a smooth, glossy finish during setting. In contrast, a regular baking sheet lacks this airflow, often causing sticky bottoms and uneven texture in delicate candies.

Precision set rack

A confectionery cooling grid offers precision set racks that ensure even air circulation around candy, preventing uneven cooling and sticky textures common on regular baking sheets. This specialized design enhances candy setting by maintaining consistent temperature and airflow, crucial for achieving optimal texture and finish.

Glassy finish staging tray

A confectionery cooling grid enhances candy setting by allowing air circulation, preventing moisture buildup, and promoting a smooth, glassy finish. In contrast, a regular baking sheet often traps heat and moisture, leading to uneven setting and duller candy surfaces.

Drip-through rack

A confectionery cooling grid features a drip-through rack design that allows excess syrup or coating to fall away, preventing pooled candy and ensuring even hardening, unlike regular baking sheets that trap drips and can cause sticky bottoms. The elevated grid promotes superior air circulation around the candy, resulting in a consistent finish and faster setting times essential for professional candy-making.

Cooling lattice for candies

A confectionery cooling grid offers superior airflow and prevents condensation, ensuring candies set evenly and retain a crisp texture. Unlike regular baking sheets, the elevated wire lattice minimizes contact with surfaces, reducing sticking and promoting faster cooling essential for delicate candy finishes.

Regular Baking Sheet vs Confectionery Cooling Grid for setting candy. Infographic

cookingdiff.com

cookingdiff.com