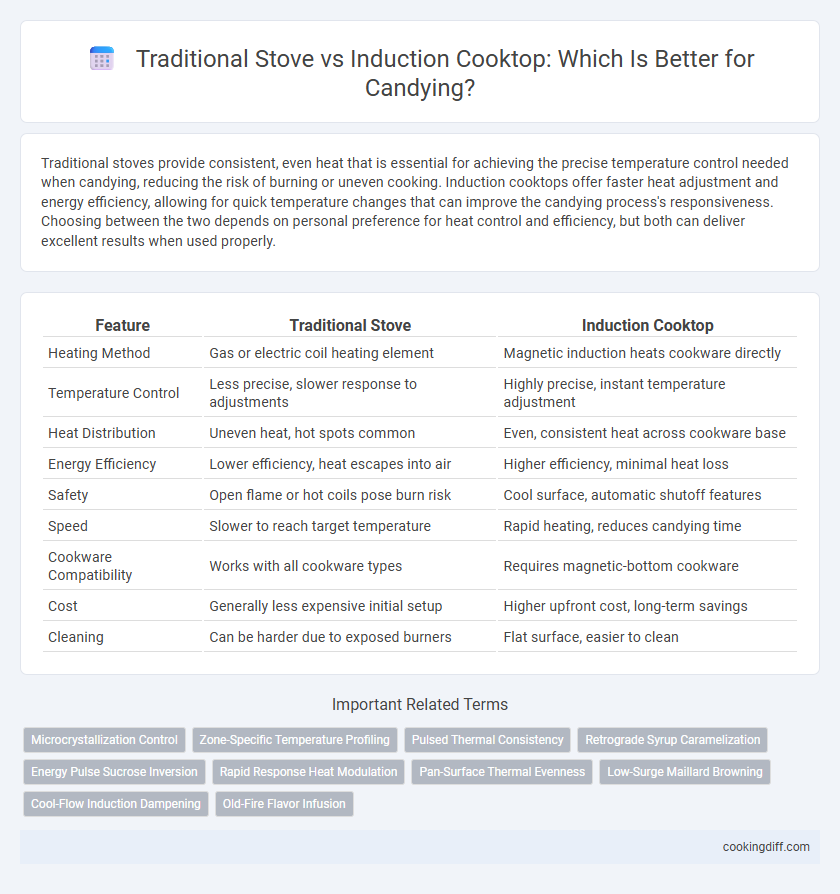

Traditional stoves provide consistent, even heat that is essential for achieving the precise temperature control needed when candying, reducing the risk of burning or uneven cooking. Induction cooktops offer faster heat adjustment and energy efficiency, allowing for quick temperature changes that can improve the candying process's responsiveness. Choosing between the two depends on personal preference for heat control and efficiency, but both can deliver excellent results when used properly.

Table of Comparison

| Feature | Traditional Stove | Induction Cooktop |

|---|---|---|

| Heating Method | Gas or electric coil heating element | Magnetic induction heats cookware directly |

| Temperature Control | Less precise, slower response to adjustments | Highly precise, instant temperature adjustment |

| Heat Distribution | Uneven heat, hot spots common | Even, consistent heat across cookware base |

| Energy Efficiency | Lower efficiency, heat escapes into air | Higher efficiency, minimal heat loss |

| Safety | Open flame or hot coils pose burn risk | Cool surface, automatic shutoff features |

| Speed | Slower to reach target temperature | Rapid heating, reduces candying time |

| Cookware Compatibility | Works with all cookware types | Requires magnetic-bottom cookware |

| Cost | Generally less expensive initial setup | Higher upfront cost, long-term savings |

| Cleaning | Can be harder due to exposed burners | Flat surface, easier to clean |

Introduction to Candying: Traditional Stove vs Induction Cooktop

Candying involves cooking sugar syrups to precise temperatures for perfect texture and flavor. Traditional stoves use direct heat, which requires careful monitoring to avoid burning or uneven cooking.

Induction cooktops offer rapid, consistent heating with precise temperature control ideal for candying. They reduce the risk of hot spots and provide energy-efficient, safer cooking environments compared to traditional stoves.

Heat Control Precision: Which Method Wins?

| Heat Control Precision | Traditional Stove | Induction Cooktop |

|---|---|---|

| Temperature Accuracy | Less precise, often fluctuates due to direct flame and uneven heating | Highly accurate, offers consistent and instant temperature adjustments |

| Response Time | Slower response to temperature changes, causing potential sugar crystallization | Rapid response, minimizing risk of burning or crystallizing candy mixtures |

| Cooking Consistency | Variable, depends on stove type and heat source stability | Consistent heat distribution, ideal for precise candying processes |

Temperature Consistency in Candying

Traditional stoves often exhibit fluctuating temperatures during candying, which can cause uneven caramelization and affect the final texture. Induction cooktops provide precise temperature control, maintaining consistent heat essential for delicate sugar work.

Maintaining stable temperature is critical in candying to avoid burning or crystallization. Induction cooktops use electromagnetic fields to deliver rapid, even heating, ensuring the sugar mixture stays within the desired temperature range. This consistency enhances the quality and appearance of homemade candies.

Safety Considerations: Induction vs Traditional Methods

Induction cooktops offer enhanced safety by using electromagnetic fields that heat only the cookware, reducing the risk of burns and accidental fires during candying. Traditional stoves rely on open flames or electric coils, increasing the chances of overheating and potential kitchen hazards. The automatic shutoff feature in many induction models further minimizes safety risks compared to conventional methods.

Energy Efficiency in Candying Techniques

Which cooking method offers better energy efficiency for candying, traditional stove or induction cooktop? Induction cooktops provide faster heat transfer directly to the cookware, reducing energy loss compared to traditional stoves that rely on flame or electric coil heating. This results in lower energy consumption and more precise temperature control during the candying process.

Time Efficiency: Cooking Speed Comparison

Induction cooktops heat cookware directly through electromagnetic fields, resulting in faster temperature rises and reduced cooking times compared to traditional stoves that rely on heat conduction from gas or electric coils. For candying, where precise temperature control and quick responses to adjustments are vital, induction cooktops offer superior time efficiency by minimizing heat lag and overshoot. Traditional stoves often require longer periods to reach and stabilize cooking temperatures, making the candying process slower and less consistent.

Equipment Compatibility for Candy Preparation

Traditional stoves offer broad compatibility with various types of cookware essential for candying, such as heavy-bottomed pots that ensure even heat distribution. Induction cooktops require magnetic cookware, typically stainless steel or cast iron, which can limit the choice of pots suitable for precise temperature control in candy preparation.

The steady, consistent heat from traditional stoves helps prevent scorching and enables gradual sugar caramelization, a critical aspect of candying. Induction cooktops provide rapid heating and precise temperature adjustments, but not all candying equipment is compatible, potentially affecting the overall cooking process.

Flavor and Texture Outcomes: Stove vs Induction

Traditional stoves provide uneven heat distribution which can lead to inconsistent candy texture and caramelization flavors. Induction cooktops offer precise and rapid temperature control, enhancing the development of smooth textures and rich, uniform flavors.

- Heat Distribution - Traditional stoves often produce hot spots causing variable cooking results, while induction cooktops heat evenly to ensure consistent candy quality.

- Temperature Precision - Induction technology allows for exact temperature maintenance critical for sugar crystallization, unlike the less responsive control of traditional stoves.

- Flavor Development - Even heating on induction cooktops promotes balanced caramelization, which improves the depth and complexity of candy flavors compared to the patchy heat of stoves.

Cleaning and Maintenance Differences

Traditional stoves often accumulate sticky residues and burnt sugar, making cleaning more labor-intensive, while induction cooktops feature smooth surfaces that resist candy spills and are easier to wipe down. Maintenance of traditional stoves requires routine checks on burners and gas lines, whereas induction cooktops primarily need careful handling of the glass surface to prevent scratches.

- Residue build-up - Traditional stoves are prone to stubborn caramelized sugar deposits that demand soaking and scrubbing.

- Surface cleaning - Induction cooktops have flat, non-porous surfaces facilitating quick and efficient cleaning.

- Maintenance tasks - Induction systems require less frequent maintenance compared to gas stove components susceptible to wear and clogging.

Induction cooktops offer a cleaner, lower-maintenance option ideal for consistent candy-making environments.

Related Important Terms

Microcrystallization Control

Traditional stoves offer uneven heat distribution that can lead to inconsistent microcrystallization during candying, affecting texture and clarity. Induction cooktops provide precise temperature control and rapid heat adjustments, enabling superior microcrystallization control for smoother, more uniform candy results.

Zone-Specific Temperature Profiling

Traditional stoves provide uneven heat distribution, leading to inconsistent temperature zones that complicate precise candying processes, whereas induction cooktops offer rapid, uniform heating with advanced zone-specific temperature control, ensuring accurate and stable temperature profiling essential for caramelization and sugar crystallization. This precise thermal management on induction cooktops reduces the risk of burning or undercooking, optimizing texture and flavor development in candy making.

Pulsed Thermal Consistency

Traditional stoves often deliver uneven heat distribution, causing fluctuations in temperature that can negatively affect the precise sugar crystallization needed for candying. Induction cooktops provide pulsed thermal consistency by rapidly adjusting heat output with electromagnetic energy, ensuring stable temperatures and more controlled cooking results crucial for high-quality candy production.

Retrograde Syrup Caramelization

Traditional stoves often cause uneven heat distribution leading to retrograde syrup caramelization, which can result in crystalline sugar formation and compromised texture in candying. Induction cooktops provide precise temperature control and rapid heat adjustments, minimizing retrograde crystallization and ensuring smooth, consistent syrup caramelization.

Energy Pulse Sucrose Inversion

Traditional stoves provide uneven heat distribution that can cause inconsistent energy pulses, potentially disrupting the sucrose inversion process critical for perfect candying. Induction cooktops deliver precise and rapid energy pulses, ensuring controlled sucrose inversion by maintaining stable temperatures essential for optimal candy texture and flavor.

Rapid Response Heat Modulation

Induction cooktops offer rapid response heat modulation, enabling precise temperature control crucial for candying sugar without burning or crystallization. Traditional stoves have slower heat adjustments, which can lead to uneven heating and affect the texture and consistency of the final candy product.

Pan-Surface Thermal Evenness

Traditional stoves often deliver uneven pan-surface thermal distribution, causing inconsistent heating and potential hotspots during candying, which can lead to scorching or crystallization issues. Induction cooktops provide precise and uniform heat distribution directly to the pan surface, ensuring consistent temperature control crucial for achieving smooth, high-quality candy textures.

Low-Surge Maillard Browning

Traditional stoves provide uneven heat distribution that can cause inconsistent Maillard browning during candying, leading to potential sugar crystallization and burnt spots. Induction cooktops offer precise temperature control and low-surge heat application, ensuring uniform Maillard reactions crucial for achieving smooth texture and optimal caramelization.

Cool-Flow Induction Dampening

Cool-Flow Induction Dampening in induction cooktops offers precise temperature control and rapid heat adjustments, essential for delicate candying processes that require exact thermal management, unlike traditional stoves which often cause uneven heat distribution and hot spots. This advanced dampening technology ensures consistent candy texture and prevents scorching, optimizing sugar crystallization and caramelization for superior confectionery results.

Traditional Stove vs Induction Cooktop for candying. Infographic

cookingdiff.com

cookingdiff.com