A stainless steel rack offers durability and stability for candying, allowing even air circulation and easy cleaning, which helps prevent sticking or uneven cooling of sweets. Stackable cooling grids maximize space efficiency by enabling multiple layers of candy to cool simultaneously, making them ideal for larger batches without compromising airflow. Choosing between the two depends on whether priority lies in long-term durability and simplicity or in maximizing cooling capacity with limited workspace.

Table of Comparison

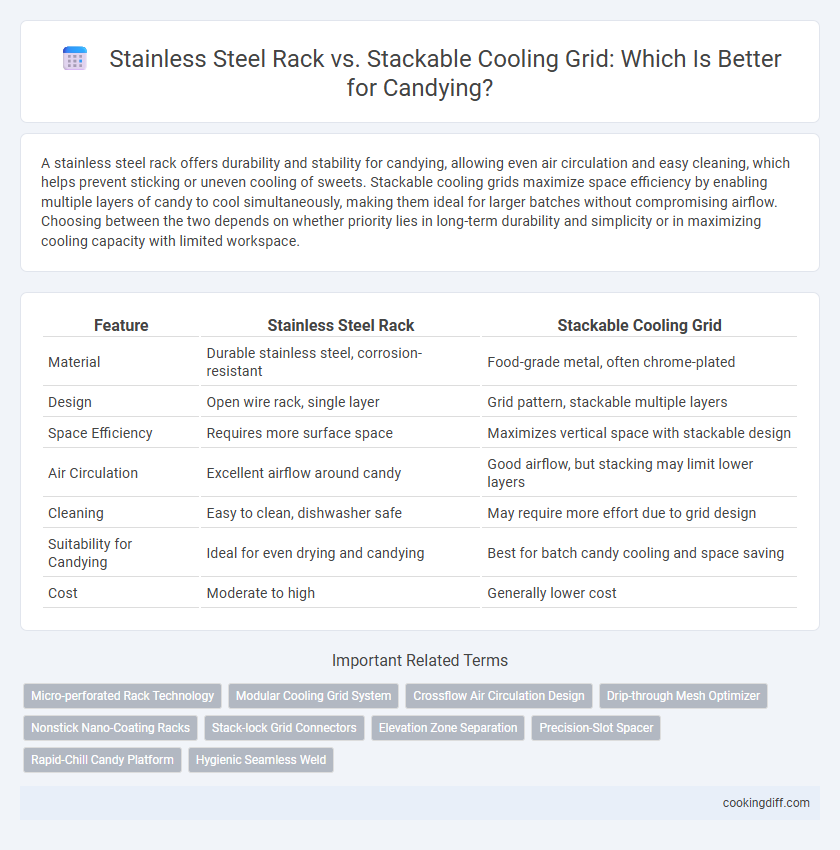

| Feature | Stainless Steel Rack | Stackable Cooling Grid |

|---|---|---|

| Material | Durable stainless steel, corrosion-resistant | Food-grade metal, often chrome-plated |

| Design | Open wire rack, single layer | Grid pattern, stackable multiple layers |

| Space Efficiency | Requires more surface space | Maximizes vertical space with stackable design |

| Air Circulation | Excellent airflow around candy | Good airflow, but stacking may limit lower layers |

| Cleaning | Easy to clean, dishwasher safe | May require more effort due to grid design |

| Suitability for Candying | Ideal for even drying and candying | Best for batch candy cooling and space saving |

| Cost | Moderate to high | Generally lower cost |

Introduction: Choosing the Right Tool for Candying

Choosing the right tool for candying significantly impacts the quality and efficiency of the final product. Stainless steel racks and stackable cooling grids each offer unique advantages tailored to different candying needs.

Stainless steel racks provide durability and easy cleaning, making them ideal for heavy-duty candying tasks. Stackable cooling grids maximize space and enhance airflow, promoting even cooling and preventing candy deformation. Selecting between these tools depends on the volume of candy and specific cooling requirements.

Overview of Stainless Steel Racks

Stainless steel racks offer durable and corrosion-resistant solutions essential for candying processes that require hygiene and longevity. Their sturdy construction supports heavy loads, making them ideal for large batches of confectionery cooling and drying.

- Durability - Stainless steel racks withstand frequent use and exposure to moisture without rusting.

- Easy Cleaning - The smooth surface facilitates quick sanitation, reducing contamination risks.

- Heat Resistance - Stainless steel tolerates high temperatures during candying without warping.

Overview of Stackable Cooling Grids

Stackable cooling grids offer a versatile solution for candying by maximizing drying space through vertical layering while maintaining proper air circulation. Made from durable stainless steel with non-stick coatings, these grids resist corrosion and simplify cleanup after sticky candy batches. Their modular design allows easy expansion, making them ideal for both small-scale candy makers and commercial operations seeking efficient cooling and drying workflows.

Material Durability and Longevity Comparison

Stainless steel racks offer superior material durability, resisting rust and corrosion even when exposed to sugary syrups and high humidity during candying. Their robust construction ensures long-term use without bending or warping.

Stackable cooling grids, often made from coated metal or plastic, may degrade faster with repeated exposure to sticky candy residues and heat variations. While stackable grids provide convenient space-saving benefits, their material longevity is generally less reliable compared to stainless steel racks in candying applications.

Airflow and Drying Efficiency

Stainless steel racks offer superior airflow due to their open design, enhancing drying efficiency during the candying process. Stackable cooling grids, while space-saving, may restrict air circulation and slow down drying times.

- Stainless Steel Rack Airflow - Open structure allows maximum air movement around candy pieces.

- Stackable Cooling Grid Space Efficiency - Enables vertical stacking to save counter space at the expense of airflow.

- Drying Speed - Better airflow from stainless steel racks results in faster moisture evaporation.

Choosing between these options depends on balancing drying efficiency with available workspace constraints.

Ease of Cleaning and Maintenance

| Type | Ease of Cleaning | Maintenance |

|---|---|---|

| Stainless Steel Rack | Non-porous surface resists stains and odors, allowing quick and thorough cleaning with standard detergents. | Durable construction resists rust and corrosion, requiring minimal upkeep to maintain hygienic conditions over time. |

| Stackable Cooling Grid | Multiple layers complicate access to crevices, making deep cleaning more time-consuming and challenging. | Frequent disassembly and reassembly necessary; plastic components may degrade or harbor residues, increasing maintenance needs. |

Space-Saving and Storage Considerations

Which option offers better space-saving benefits for candying, a stainless steel rack or a stackable cooling grid? Stainless steel racks provide sturdy, multi-tiered support that maximizes vertical storage, ideal for small kitchens. Stackable cooling grids allow customized layering and compact nesting, making them highly versatile and easy to store when not in use.

Versatility for Various Candying Recipes

Stainless steel racks offer superior versatility for candying a wide range of treats due to their sturdy construction and multiple tier options, allowing for efficient air circulation and even cooling. They accommodate various candy sizes and shapes, making them ideal for both small batches of delicate bonbons and larger confections like caramel apples.

Stackable cooling grids provide compact storage and easy synchronization for multiple candy layers, enhancing workflow in busy kitchens. Their modular design supports consistent temperature control and quick adjustments, which is crucial for recipes requiring precise cooling conditions such as fudge and brittle.

Price and Value Analysis

Stainless steel racks typically come at a higher initial cost compared to stackable cooling grids, which are more budget-friendly. However, the durability and corrosion resistance of stainless steel racks offer greater long-term value for frequent candying tasks.

- Cost Efficiency - Stackable cooling grids are cheaper upfront, making them ideal for occasional candy makers.

- Durability - Stainless steel racks resist rust and wear, extending their lifespan and reducing replacement frequency.

- Value Proposition - Investing in stainless steel racks provides better performance and saves money over time despite a higher purchase price.

Related Important Terms

Micro-perforated Rack Technology

Micro-perforated stainless steel racks enhance airflow and moisture control during candying, preventing sogginess and ensuring even drying compared to stackable cooling grids. This advanced design promotes quicker dehydration and superior texture in candied products, optimizing quality and shelf life.

Modular Cooling Grid System

A modular cooling grid system offers a stackable design that maximizes airflow and space efficiency during candying, ensuring even cooling and preventing stickiness. In contrast, stainless steel racks provide durability but lack the flexibility and optimized ventilation of stackable grids, making modular grids superior for scalable candy production.

Crossflow Air Circulation Design

Stainless steel racks with crossflow air circulation design enhance candying by allowing even airflow around each piece, promoting uniform drying and preventing sogginess. Stackable cooling grids often restrict airflow between layers, which can lead to uneven texture and longer drying times during the candying process.

Drip-through Mesh Optimizer

Stainless steel racks with drip-through mesh optimize airflow and drainage during candying, preventing moisture buildup and ensuring even drying of candies. Stackable cooling grids may lack this mesh design, reducing air circulation efficiency and increasing the risk of sticky or unevenly cured sweets.

Nonstick Nano-Coating Racks

Nonstick nano-coating racks provide superior release and easy cleanup compared to traditional stainless steel racks, preventing candy from sticking during the candying process. Stackable cooling grids with this advanced coating maximize airflow while saving space, enhancing candy texture and cooling efficiency.

Stack-lock Grid Connectors

Stack-lock grid connectors on stackable cooling grids provide enhanced stability and efficient airflow, ensuring evenly candied treats without structural collapse. Stainless steel racks offer durability but lack the modular flexibility and precise alignment that stack-lock connectors deliver for optimized candying processes.

Elevation Zone Separation

Stainless steel racks provide robust elevation zone separation, allowing for optimal air circulation and even candy drying by spacing layers precisely. Stackable cooling grids offer flexible, compact layering but may limit airflow between zones, potentially affecting the uniformity of candy texture and finish.

Precision-Slot Spacer

The Stainless Steel Rack with Precision-Slot Spacers offers superior airflow control and uniform cooling for candying, ensuring consistent texture and preventing candy from sticking. Stackable Cooling Grids lack these precision slots, which can lead to uneven cooling and reduced efficiency in the candying process.

Rapid-Chill Candy Platform

The Rapid-Chill Candy Platform features a stainless steel rack that offers superior durability and corrosion resistance compared to stackable cooling grids, ensuring hygienic and long-lasting use during candying. Its design promotes optimal air circulation, accelerating the cooling process and enhancing candy texture and quality.

Stainless Steel Rack vs Stackable Cooling Grid for candying. Infographic

cookingdiff.com

cookingdiff.com