Candying involves soaking fruits in sugar syrup to achieve a sweet, chewy texture by replacing water with sugar, enhancing shelf life and flavor. Vacuum impregnation modifies texture by applying vacuum pressure to infuse liquids into porous fruits or vegetables, allowing precise control over moisture content and firmness without altering taste significantly. Compared to candying, vacuum impregnation offers more versatility in texture modification while maintaining the product's original nutritional and sensory properties.

Table of Comparison

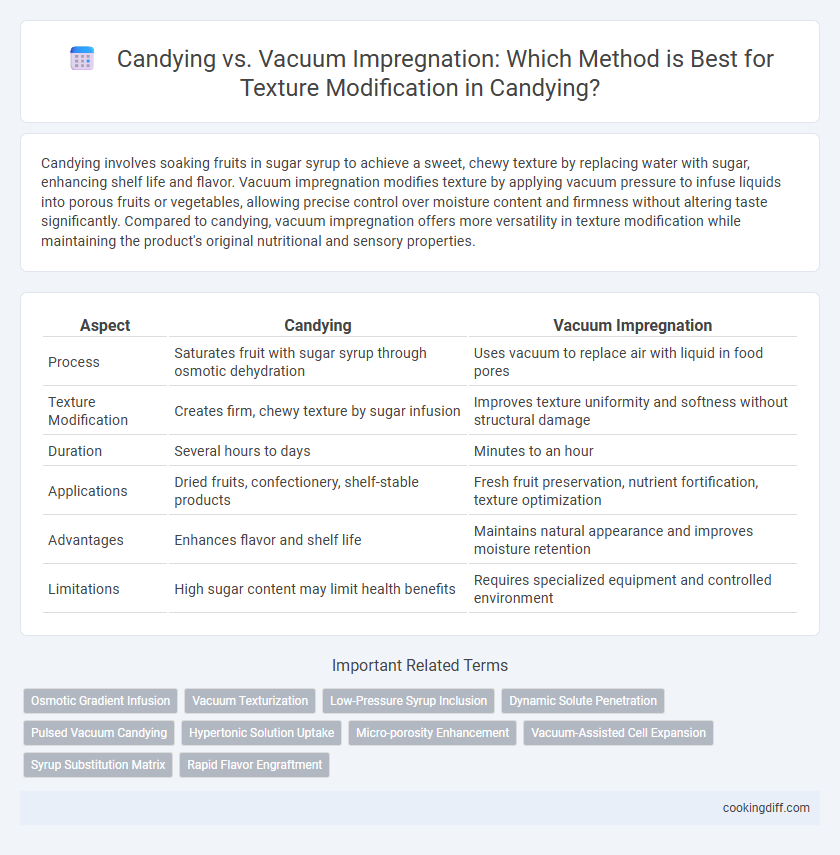

| Aspect | Candying | Vacuum Impregnation |

|---|---|---|

| Process | Saturates fruit with sugar syrup through osmotic dehydration | Uses vacuum to replace air with liquid in food pores |

| Texture Modification | Creates firm, chewy texture by sugar infusion | Improves texture uniformity and softness without structural damage |

| Duration | Several hours to days | Minutes to an hour |

| Applications | Dried fruits, confectionery, shelf-stable products | Fresh fruit preservation, nutrient fortification, texture optimization |

| Advantages | Enhances flavor and shelf life | Maintains natural appearance and improves moisture retention |

| Limitations | High sugar content may limit health benefits | Requires specialized equipment and controlled environment |

Introduction to Texture Modification in Foods

Texture modification in foods enhances sensory appeal and extends shelf life by altering physical properties like hardness, chewiness, and moisture retention. Candying and vacuum impregnation are two distinct techniques used to achieve desired textural changes, especially in fruits and confections.

Candying involves soaking food in sugar solutions to replace water with syrup, resulting in a firm and sweet product with prolonged preservation. Vacuum impregnation uses pressure differentials to infuse liquid agents into the food matrix, enabling precise control over texture and flavor distribution. Both methods manipulate texture but differ significantly in mechanism, application, and impact on product quality.

Overview of the Candying Process

How does the candying process alter the texture of fruits and vegetables? Candying involves soaking produce in a sugar syrup that penetrates the cellular structure, resulting in a firm yet tender texture. This method enhances sweetness while preserving the shape and color of the food, distinguishing it from vacuum impregnation techniques.

Principles of Vacuum Impregnation

Vacuum impregnation involves the removal of air from a porous food matrix under reduced pressure, allowing for the infusion of a liquid solution that modifies texture, flavor, or nutritional properties. The vacuum phase creates voids within the product that are subsequently filled during the atmospheric restoration phase, enhancing penetration depth and uniformity.

This method contrasts with traditional candying by enabling precise control over the liquid uptake without extended exposure to high sugar concentrations, preserving structural integrity. Vacuum impregnation is particularly effective for fruits and vegetables where texture retention and reduced processing times are critical.

Comparing Mechanisms: Candying vs. Vacuum Impregnation

Candying preserves fruit texture by gradually replacing water with concentrated sugar syrup through osmotic diffusion, resulting in a firm yet tender consistency. Vacuum impregnation modifies texture by applying reduced pressure to create micro-pores, allowing enhanced infusion of solutes directly into the fruit's cellular structure. Both methods target texture enhancement but differ fundamentally in their mechanisms: candying relies on osmotic dehydration, while vacuum impregnation uses pressure-driven solute penetration.

Impact on Food Texture and Mouthfeel

Candying enhances food texture by infusing sugar crystals, creating a firmer and chewier mouthfeel that prolongs sensory enjoyment. Vacuum impregnation modifies texture by introducing liquids under reduced pressure, resulting in a more uniform and softer product with improved juiciness.

- Candying increases structural rigidity - sugar crystallization reinforces cellular structure, producing a crisp and chewy texture.

- Vacuum impregnation promotes internal hydration - fluids penetrate deeper, softening the tissue without compromising integrity.

- Candying extends shelf life through sugar content - the hypertonic environment reduces moisture activity, maintaining texture over time.

Texture modification techniques directly influence sensory perception and consumer acceptability through distinct mechanical and hydration mechanisms.

Flavor Enhancement: Differences Between Methods

Candying enhances flavor primarily through sugar infusion, creating a sweet, preserved exterior that intensifies taste over time. Vacuum impregnation modifies texture and flavor by removing air and introducing liquid flavor solutions directly into the product, achieving a more uniform and immediate flavor enhancement.

- Candying flavor infusion - Utilizes prolonged soaking in sugar syrup to saturate the surface and slightly penetrate the interior.

- Vacuum impregnation precision - Employs vacuum pressure to replace air with flavor agents, enabling deeper and faster flavor permeation.

- Texture impact differences - Candying results in a firmer, glossy texture, whereas vacuum impregnation maintains original texture while enhancing juiciness and flavor.

Nutritional Effects of Each Technique

| Technique | Nutritional Effects |

|---|---|

| Candying | Increases sugar content and caloric value, potentially reducing vitamin retention due to heat exposure; antioxidants may degrade during the prolonged cooking process. |

| Vacuum Impregnation | Enhances nutrient fortification by allowing efficient infusion of vitamins and minerals without significant thermal damage; preserves natural antioxidants and bioactive compounds better than candying. |

Applications in Culinary and Food Industry

Candying enhances texture by infusing sugar syrup into fruits, creating a sweet, firm bite widely favored in confectionery. Vacuum impregnation modifies texture by removing air and injecting flavorful solutions, improving moisture retention in dried or processed foods.

- Culinary Applications of Candying - Used primarily for preservation and flavor intensification in fruits like cherries, citrus peels, and ginger.

- Vacuum Impregnation in Food Industry - Applied to optimize moisture content and texture in products such as dried vegetables, meat analogues, and bakery goods.

- Texture Modification Benefits - Candying produces a denser, sweeter product, while vacuum impregnation maintains natural texture and enhances rehydration capacity.

Advantages and Limitations of Candying and Vacuum Impregnation

Candying enhances texture by infusing fruits with sugar syrup, creating a firm, chewy consistency ideal for confectionery applications. Its advantage lies in simplicity and long shelf life, but it often results in high sugar content and potential nutrient loss.

Vacuum impregnation modifies texture by removing air and replacing it with a liquid solution, allowing precise control over moisture and nutrient retention. This method offers improved texture uniformity and reduced processing time but requires expensive equipment and technical expertise.

Related Important Terms

Osmotic Gradient Infusion

Candying relies on osmotic gradient infusion to draw sugar into fruits, enhancing sweetness and preserving texture through gradual dehydration and concentration of solutes. Vacuum impregnation accelerates this process by applying reduced pressure to remove air and facilitate deeper and more uniform penetration of osmotic solutions, resulting in improved texture modification and shorter processing times.

Vacuum Texturization

Vacuum impregnation offers precise texture modification by removing air from porous food structures and replacing it with a sugar solution, resulting in enhanced firmness and uniform sweetness compared to traditional candying methods. This technique ensures consistent product quality and improved shelf life by enabling better control over moisture content and solute distribution within the food matrix.

Low-Pressure Syrup Inclusion

Low-pressure syrup inclusion in candying allows gradual infusion of sugar syrup into fruit tissues, enhancing texture by maintaining cell integrity and firmness. Vacuum impregnation accelerates syrup penetration but can alter texture by expanding pores and softening the fruit structure, making low-pressure candying preferable for controlled texture modification.

Dynamic Solute Penetration

Dynamic solute penetration in candying uses osmotic gradients to infuse sugar into fruit tissues, resulting in a firmer and sweeter texture through slow diffusion. Vacuum impregnation enhances this process by applying reduced pressure to force solutes rapidly into cellular voids, achieving more uniform texture modification and improved solute retention.

Pulsed Vacuum Candying

Pulsed Vacuum Candying enhances texture modification by cyclically applying vacuum pressure, allowing deeper and more uniform infusion of sugar solutions compared to traditional candying methods, which often result in uneven penetration. This technique outperforms standard Vacuum Impregnation by optimizing mass transfer rates and preserving the structural integrity of fruits, leading to a superior texture in candied products.

Hypertonic Solution Uptake

Candying involves immersing fruit in hypertonic sugar solutions, promoting solute penetration that alters texture by water withdrawal and solute uptake. Vacuum impregnation enhances hypertonic solution uptake by creating vacuum-induced pressure differentials, improving the infusion of solutes into fruit tissues and resulting in more homogeneous and controlled texture modification.

Micro-porosity Enhancement

Candying enhances micro-porosity in fruits by osmotic dehydration that concentrates sugar molecules within cellular structures, creating a firm yet tender texture. Vacuum impregnation further improves micro-porosity by using reduced pressure to infuse liquids into porous matrices, resulting in more uniform texture modification and better retention of flavor and nutrients.

Vacuum-Assisted Cell Expansion

Vacuum-assisted cell expansion in vacuum impregnation enhances texture modification by promoting deeper and more uniform infusion of solutes into plant tissues, resulting in improved crispness and juiciness compared to traditional candying methods. This technique minimizes structural collapse and maintains cell integrity, offering superior control over texture and flavor penetration in fruit processing.

Syrup Substitution Matrix

Candying uses a syrup substitution matrix that gradually replaces water in fruit cells with concentrated sugar solutions, enhancing texture and sweetness through osmotic dehydration. Vacuum impregnation modifies texture more rapidly and uniformly by creating a pressure differential that forces syrup into fruit pores, allowing precise control over syrup concentration and distribution.

Candying vs Vacuum Impregnation for texture modification. Infographic

cookingdiff.com

cookingdiff.com