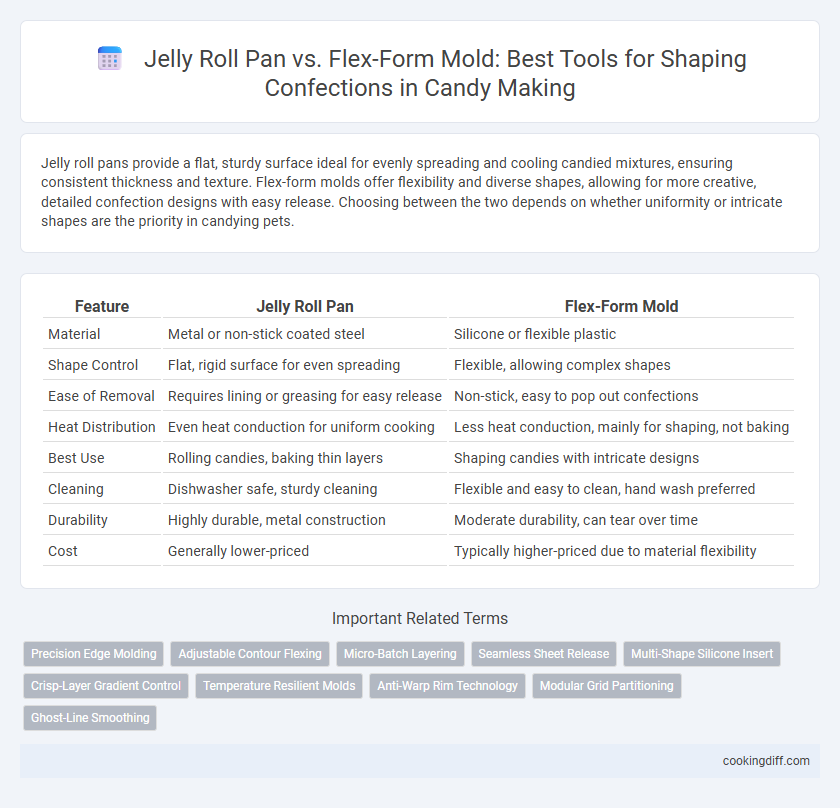

Jelly roll pans provide a flat, sturdy surface ideal for evenly spreading and cooling candied mixtures, ensuring consistent thickness and texture. Flex-form molds offer flexibility and diverse shapes, allowing for more creative, detailed confection designs with easy release. Choosing between the two depends on whether uniformity or intricate shapes are the priority in candying pets.

Table of Comparison

| Feature | Jelly Roll Pan | Flex-Form Mold |

|---|---|---|

| Material | Metal or non-stick coated steel | Silicone or flexible plastic |

| Shape Control | Flat, rigid surface for even spreading | Flexible, allowing complex shapes |

| Ease of Removal | Requires lining or greasing for easy release | Non-stick, easy to pop out confections |

| Heat Distribution | Even heat conduction for uniform cooking | Less heat conduction, mainly for shaping, not baking |

| Best Use | Rolling candies, baking thin layers | Shaping candies with intricate designs |

| Cleaning | Dishwasher safe, sturdy cleaning | Flexible and easy to clean, hand wash preferred |

| Durability | Highly durable, metal construction | Moderate durability, can tear over time |

| Cost | Generally lower-priced | Typically higher-priced due to material flexibility |

Overview: Candying Techniques with Jelly Roll Pan vs Flex-Form Mold

The jelly roll pan offers a flat, sturdy surface ideal for pouring and spreading candy mixtures evenly, enhancing quick cooling and easy cutting. Flex-form molds, made from silicone, provide flexibility and intricate shapes for detailed confection designs, improving aesthetic appeal.

When candying, the jelly roll pan is preferred for recipes requiring uniform thickness, such as brittle or toffee, due to its consistent heat distribution and rigid structure. Flex-form molds excel in creating shaped gummies or chocolates with precise edges and decorative details, thanks to their non-stick and flexible material. Choosing between these tools depends on the desired texture, presentation, and ease of candy removal during the confectioning process.

Material Differences: Metal vs Silicone in Confection Shaping

Jelly roll pans are typically made of metal, offering superior heat conduction for even cooking and browning of confections. Flex-form molds, made from silicone, provide flexibility that makes demolding delicate candies easier without damage.

- Metal Conductivity - Jelly roll pans distribute heat efficiently, ensuring consistent texture and caramelization in candy-making.

- Silicone Flexibility - Flex-form molds allow for easy removal of sticky or intricate-shaped candies without breaking.

- Durability and Maintenance - Metal pans are prone to rust but withstand higher temperatures, while silicone molds resist corrosion and are dishwasher safe.

Versatility: Types of Confections Each Tool Handles Best

The jelly roll pan excels in versatility for candying, handling a variety of confections such as nougats, toffees, and brittle due to its flat, rimmed surface that promotes even cooking and easy cooling. Its rim allows for shaping sheet candies that can be easily cut into uniform pieces once set.

The Flex-Form mold specializes in shaping intricate or themed confections like molded chocolates and caramels, providing precise detail and consistent shapes through its flexible silicone material. This tool is ideal for candies requiring detailed presentation and delicate removal without damage.

Ease of Use: User Experience with Jelly Roll Pan and Flex-Form Mold

| Jelly Roll Pan | Provides a flat, non-stick surface that simplifies spreading and cooling candy mixtures evenly, reducing the risk of sticking or burning during the candying process. |

| Flex-Form Mold | Features flexible silicone material that allows easy removal of shaped confections without damage, enhancing user convenience especially for intricate candy designs. |

| User Experience | Jelly Roll pans suit beginners requiring simple handling and easy cleanup, while Flex-Form molds cater to advanced users focused on precision and variety in candy shapes. |

Precision & Consistency: Achieving Uniformity in Candy Shapes

Jelly roll pans offer a flat, rigid surface that ensures even thickness and uniform heat distribution for consistent candy shapes during candying. Flex-form molds provide precise cavities that maintain exact shape and size, ideal for detailed and repeatable confection designs. Both tools enhance precision and consistency, but molds excel in replicating intricate shapes while pans suit larger, flat candies.

Release & Cleanup: Nonstick Performance Compared

Jelly roll pans offer a flat surface with a moderately effective nonstick coating that aids in removing candies without significant residue. Flex-form molds feature superior nonstick silicone that ensures easy release and minimal stickiness, enhancing cleanup efficiency.

- Jelly Roll Pan Nonstick Performance - Coated steel surfaces can sometimes require light greasing to prevent sticking.

- Flex-Form Mold Silicone Quality - High-grade silicone provides flexible edges that allow candies to pop out cleanly.

- Cleanup Efficiency - Jelly roll pans may need more scrubbing, while flex-form molds generally rinse clean with minimal effort.

Choosing flex-form molds significantly reduces time spent on release and cleanup when candying confections.

Temperature Tolerance: Baking and Setting Considerations

The Jelly Roll Pan offers high temperature tolerance, making it ideal for candying processes that require baking or setting at elevated temperatures up to 450degF. In contrast, the Flex-Form Mold, typically made from silicone, withstands temperatures ranging from -40degF to 500degF, allowing versatile use for both freezing and baking confections. Choosing the right mold depends on the specific temperature demands of your candy recipe to ensure proper setting and optimal texture.

Storage & Space Efficiency for Candy Makers

Which option offers better storage and space efficiency for candy makers, a jelly roll pan or a Flex-Form mold? Jelly roll pans are stackable and can fit easily in standard kitchen cabinets, making them ideal for limited storage spaces. Flex-Form molds, while flexible for removing confections, often require more specific storage conditions to maintain their shape and can take up more room due to their irregular form.

Cost Analysis: Investment Value for Home Confectioners

Jelly roll pans typically cost between $10 to $20, offering an affordable option for home confectioners with their durable aluminum construction and versatile use for candying. Flex-form molds range from $15 to $40, reflecting their specialized silicone material designed for intricate shapes and easy candy release, which can enhance the presentation of confections.

Considering long-term investment, jelly roll pans provide multi-purpose functionality beyond candying, making them economically efficient for beginners. Flex-form molds, while pricier upfront, reduce post-candying cleanup time and minimize product waste, ultimately adding value for serious home confectioners focused on precise shaping and quality results.

Related Important Terms

Precision Edge Molding

Jelly Roll Pans provide a flat, even surface ideal for spreading candy mixtures uniformly, but lack the precision edge molding required for intricate shapes. Flex-Form Molds offer superior precision edge molding capabilities, allowing confections to hold detailed, defined contours essential for professional candying results.

Adjustable Contour Flexing

The Flex-Form Mold offers superior adjustable contour flexing, allowing confectioners to shape candy with precise curves and intricate details unattainable by the rigid, flat surface of a Jelly Roll Pan. This flexibility enhances the crafting of uniquely contoured candies, improving both aesthetic appeal and uniformity in candy production.

Micro-Batch Layering

Jelly roll pans provide a flat, wide surface ideal for even spreading and cooling of candy layers in micro-batch layering, ensuring consistent thickness and texture in confections. Flex-form molds offer precise shaping and easy removal, perfect for more intricate designs requiring detailed micro-batch layering in candying processes.

Seamless Sheet Release

Jelly roll pans offer a flat, sturdy surface that ensures even cooking and easy removal of candied confections without sticking or tearing. Flex-form molds provide seamless sheet release with flexible silicone material, allowing delicate candies to maintain their shape and texture while effortlessly popping out.

Multi-Shape Silicone Insert

The Multi-Shape Silicone Insert enhances flexibility in candying by fitting perfectly into both Jelly Roll Pans and Flex-Form Molds, allowing candy makers to create intricate shapes with ease and precision. Its heat-resistant, non-stick surface ensures even cooking and smooth release, optimizing the confectionery process for complex and uniform candies.

Crisp-Layer Gradient Control

A Jelly Roll Pan offers precise control over crisp-layer gradients due to its shallow depth and even heat distribution, ideal for thin, uniform candy layers. Flex-Form Molds provide versatility in shape but may result in less consistent crispness, as their flexible material can cause uneven caramelization.

Temperature Resilient Molds

Jelly roll pans provide excellent heat conduction for candying processes but may lack the flexibility needed for delicate shapes, whereas Flex-Form molds offer superior temperature resilience and non-stick properties that ensure precise candy shaping without deformation or melting. Temperature resilient molds resist warping and withstand the high heat of candying, preserving the integrity and texture of confections during cooling and setting phases.

Anti-Warp Rim Technology

Jelly roll pans with Anti-Warp Rim Technology provide superior stability during candying by preventing distortion at high temperatures, ensuring even cooking and consistent shape retention. In contrast, flex-form molds, while flexible for intricate designs, lack this anti-warp feature, making them more prone to deformation and uneven heat distribution.

Modular Grid Partitioning

Jelly roll pans offer a rigid, uniform surface ideal for modular grid partitioning, enabling precise segmenting of confections into consistent portions during candying. Flex-form molds provide flexible compartments that support customized grid partitioning, allowing for varied shapes and sizes while maintaining structural integrity in the candying process.

Jelly Roll Pan vs Flex-Form Mold for shaping confections. Infographic

cookingdiff.com

cookingdiff.com