Metal dipping forks offer sturdy construction and heat resistance, making them ideal for handling hot sugar without bending or melting. Precision dipping tools provide finer control for delicate candying tasks, allowing for more even coating and intricate designs. Choosing between the two depends on the complexity of your candying project and the level of detail required.

Table of Comparison

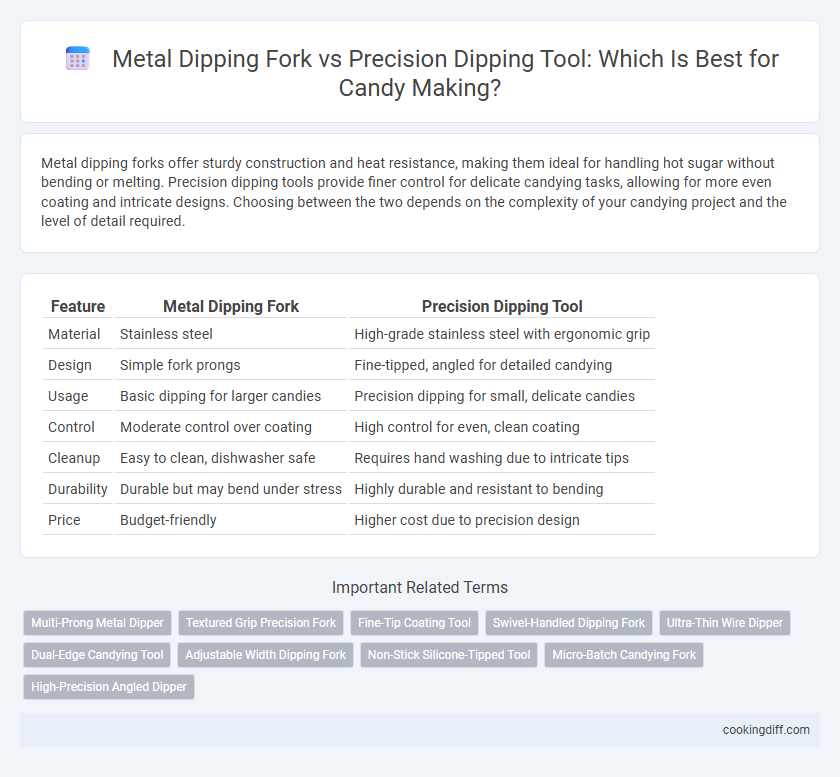

| Feature | Metal Dipping Fork | Precision Dipping Tool |

|---|---|---|

| Material | Stainless steel | High-grade stainless steel with ergonomic grip |

| Design | Simple fork prongs | Fine-tipped, angled for detailed candying |

| Usage | Basic dipping for larger candies | Precision dipping for small, delicate candies |

| Control | Moderate control over coating | High control for even, clean coating |

| Cleanup | Easy to clean, dishwasher safe | Requires hand washing due to intricate tips |

| Durability | Durable but may bend under stress | Highly durable and resistant to bending |

| Price | Budget-friendly | Higher cost due to precision design |

Introduction to Candying: Tools Matter

Metal dipping forks are essential in candying for efficiently lifting and coating large batches of confections, offering durability and heat resistance. They provide a sturdy grip that helps maintain consistency during the candying process.

Precision dipping tools are designed for intricate work, allowing candy makers to handle delicate decorations with accuracy and control. These tools minimize excess coating and enhance the aesthetic quality of finished candies.

Metal Dipping Fork: Traditional Choice

Why is the metal dipping fork considered the traditional choice for candying? The metal dipping fork offers sturdy construction and heat resistance, making it ideal for handling hot candy with ease. Its simple design provides a reliable grip for dipping and cooling confections, ensuring consistent results in classic candy-making processes.

Precision Dipping Tool: Modern Alternative

The Precision Dipping Tool offers superior control and accuracy compared to the traditional Metal Dipping Fork, making it ideal for intricate candying tasks. Designed with ergonomic features and fine-tipped edges, it enhances the candy coating process by reducing mess and improving coating consistency. As a modern alternative, it supports professional and home candy makers in achieving perfect, uniform candy finishes every time.

Design Differences: Fork vs Precision Tool

The metal dipping fork features a simple, open-prong design ideal for quickly submerging candies in syrup or chocolate, while the precision dipping tool incorporates a narrower, more controlled tip for detailed candy coating. The design differences impact usability; the fork suits larger batches, whereas the precision tool is optimized for intricate or delicate candy work.

- Prong vs Tip Design - Metal dipping forks have wide, spaced prongs, whereas precision tools have a narrow, pointed tip.

- Batch Handling - Forks facilitate dipping multiple candies simultaneously, while precision tools enable single-piece, detailed coating.

- Control and Accuracy - Precision dipping tools offer enhanced control for delicate finishes unlike the broader approach of metal forks.

Handling and Control: Which Tool Wins?

Metal dipping forks offer sturdy handling and are ideal for larger candy batches, providing firm control during immersion. Precision dipping tools, crafted with ergonomic designs and finer tips, excel in managing delicate candy items with superior accuracy. For tasks demanding intricate detail and gentle manipulation, precision dipping tools clearly win in handling and control.

Candy Surface Finish: Smoothness and Quality

| Metal Dipping Fork | Provides a sturdy grip for dipping but can leave minor surface imperfections on candy due to uneven metal prongs. This tool may result in slightly textured finishes, affecting the overall smoothness and glossiness of the candy coating. |

| Precision Dipping Tool | Designed for fine control and minimal contact area, it ensures an ultra-smooth, high-quality candy surface by reducing air bubbles and streaks. The polished finish of these tools enhances candy appearance with consistent, glossy coatings. |

Versatility for Different Candies

The metal dipping fork offers excellent versatility for various candies, allowing easy coating and shaping of chocolate, caramel, and sugar confections. Its sturdy prongs accommodate larger or irregularly shaped treats, making it suitable for dipping diverse candy types.

The precision dipping tool excels in handling delicate candies like truffles or bonbons, providing controlled coverage and fine detailing. Its slim design enables intricate decoration and minimal mess, ideal for gourmet or artisanal candy making. Both tools enhance candying processes, but choice depends on the type and size of the candy being dipped.

Cleaning and Maintenance Requirements

Metal dipping forks require thorough cleaning to remove sticky sugar residues that can harden and affect future batches, often needing soaking and scrubbing. Precision dipping tools, designed with smooth surfaces and minimal crevices, simplify maintenance by reducing residue buildup and allowing quick dishwasher-safe cleaning.

- Metal Dipping Forks accumulate sugar residue - This residue can harden and demand intensive scrubbing and soaking for effective cleaning.

- Precision Dipping Tools feature smooth surfaces - Their design minimizes residue buildup, making cleaning faster and more efficient.

- Dishwasher safety varies - Precision tools are often dishwasher-safe, while metal forks typically require hand washing to prevent rust and damage.

Price Comparison: Investment vs Value

Metal dipping forks offer an affordable entry point for candying enthusiasts, while precision dipping tools demand a higher initial investment but provide enhanced control and durability. The value derived from precision tools often outweighs their price due to increased efficiency and professional results.

- Cost Efficiency - Metal dipping forks are budget-friendly, suitable for casual or occasional candying tasks.

- Durability - Precision dipping tools typically feature robust construction, ensuring long-term use and reliability.

- Performance - Precision tools deliver greater accuracy and cleaner candy coatings, justifying their higher price.

Investing in a precision dipping tool provides superior value for serious candy makers seeking consistent quality.

Related Important Terms

Multi-Prong Metal Dipper

The Multi-Prong Metal Dipper offers superior efficiency and control in candying by allowing multiple candies to be dipped simultaneously, enhancing productivity compared to a single-point Precision Dipping Tool. Its sturdy stainless steel construction ensures durability and consistent coating, making it ideal for repetitive candy dipping tasks where uniform coverage is essential.

Textured Grip Precision Fork

The Textured Grip Precision Dipping Fork offers superior control and accuracy when candying delicate confections, reducing slippage and ensuring even coating compared to standard metal dipping forks. Its ergonomic design enhances dexterity for detailed work, making it an essential tool for professional candy makers aiming for flawless results.

Fine-Tip Coating Tool

Fine-tip coating tools offer superior precision for candying by allowing exact control over dipping thickness and uniform coverage on delicate confections. Compared to metal dipping forks, these tools reduce excess coating buildup and minimize mess, making them ideal for intricate candy decoration and consistent finishing.

Swivel-Handled Dipping Fork

The swivel-handled dipping fork offers enhanced maneuverability and control during candying, making it ideal for evenly coating delicate confections with molten sugar or chocolate. Its rotating handle reduces hand fatigue and allows for precise dips compared to traditional metal dipping forks, resulting in smoother finishes and consistent candy textures.

Ultra-Thin Wire Dipper

The Ultra-Thin Wire Dipper, a precision dipping tool, offers unparalleled accuracy and finesse for candying delicate confections, outperforming traditional metal dipping forks in achieving smooth, even coatings. Its fine wire design minimizes excess coating and enhances control during the dipping process, essential for professional candy makers aiming for flawless, glossy finishes.

Dual-Edge Candying Tool

The Dual-Edge Candying Tool combines the stability of a Metal Dipping Fork with the accuracy of a Precision Dipping Tool, offering enhanced control for evenly coating candies in sugar or chocolate. Its unique design ensures efficient handling, reducing mess and improving the finish quality of dipped confections.

Adjustable Width Dipping Fork

The adjustable width dipping fork offers superior versatility in candying by allowing precise control over the fork's prong spacing, accommodating various candy sizes and shapes for consistent coating. Unlike fixed-size precision dipping tools, the adjustable width fork enhances efficiency and reduces waste by ensuring a perfect dip every time.

Non-Stick Silicone-Tipped Tool

Non-stick silicone-tipped precision dipping tools provide superior control and prevent candy from sticking, ensuring smooth, even coating compared to standard metal dipping forks. These tools enhance candying efficiency by offering heat resistance and flexibility, ideal for delicate confections requiring flawless finishes.

Micro-Batch Candying Fork

The Micro-Batch Candying Fork offers precise control and reduced product loss compared to traditional metal dipping forks, making it ideal for small-scale candying operations. Its fine tines ensure uniform coating and easy handling of delicate confections during the candying process.

Metal Dipping Fork vs Precision Dipping Tool for Candying. Infographic

cookingdiff.com

cookingdiff.com