Candying involves coating fruit in sugar syrup to preserve moisture and create a chewy texture, while dehydrator candying removes water through controlled heat, resulting in a drier, more shelf-stable product. Moisture control in candying helps prevent spoilage and maintain the candy's desired consistency. The choice between candying and dehydrator processes depends on the preferred texture and storage requirements for the final product.

Table of Comparison

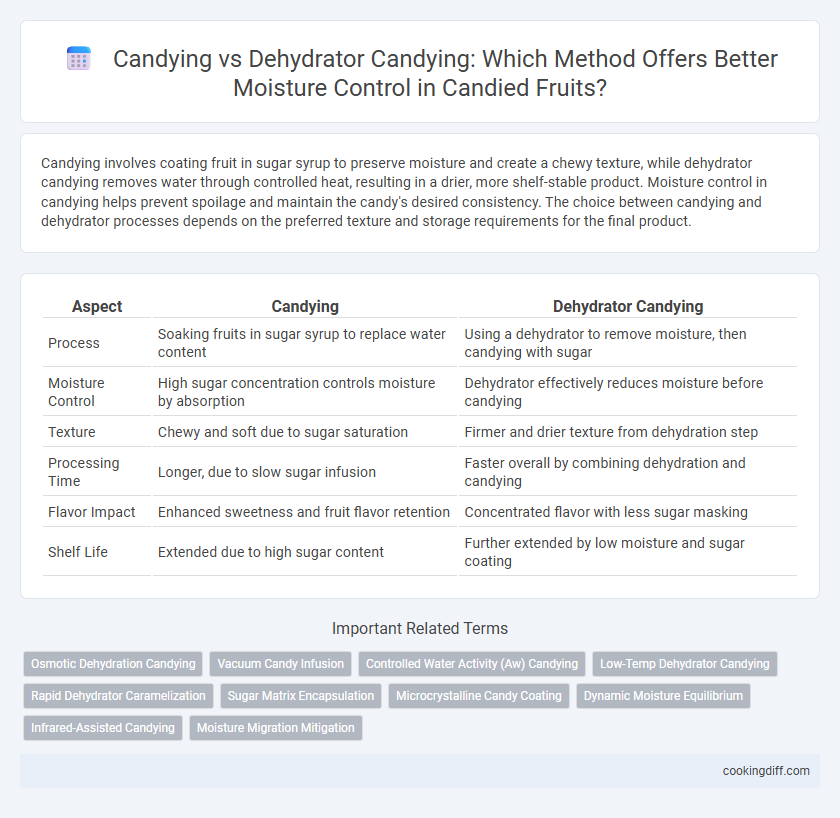

| Aspect | Candying | Dehydrator Candying |

|---|---|---|

| Process | Soaking fruits in sugar syrup to replace water content | Using a dehydrator to remove moisture, then candying with sugar |

| Moisture Control | High sugar concentration controls moisture by absorption | Dehydrator effectively reduces moisture before candying |

| Texture | Chewy and soft due to sugar saturation | Firmer and drier texture from dehydration step |

| Processing Time | Longer, due to slow sugar infusion | Faster overall by combining dehydration and candying |

| Flavor Impact | Enhanced sweetness and fruit flavor retention | Concentrated flavor with less sugar masking |

| Shelf Life | Extended due to high sugar content | Further extended by low moisture and sugar coating |

Understanding Candying: Traditional Techniques Explained

Candying involves preserving fruits by soaking them in sugar syrup, which helps retain moisture and texture. This traditional technique contrasts with dehydrator candying that uses controlled heat to remove moisture more efficiently without altering natural flavors.

- Traditional Candying - Fruits are slowly cooked in sugar syrup, allowing sugar to penetrate and preserve moisture within the fruit.

- Dehydrator Candying - Uses low heat to gradually remove moisture, maintaining a firmer texture while concentrating natural sweetness.

- Moisture Control - Traditional candying retains higher moisture levels, whereas dehydrator candying results in drier, more shelf-stable products.

Dehydrator Candying: Modern Methods for Moisture Removal

How does dehydrator candying compare to traditional candying methods in controlling moisture? Dehydrator candying uses advanced technology to precisely regulate temperature and airflow, ensuring consistent moisture removal and extended shelf life. This modern method prevents microbial growth while preserving the candy's texture and flavor better than conventional candying techniques.

Key Differences in Moisture Control

Candying involves soaking fruit in sugar syrup, which replaces water content and preserves moisture by creating a syrup-infused texture. Dehydrator candying removes moisture through controlled heat, resulting in a drier, chewier product with longer shelf life. The key difference lies in moisture retention--candying maintains softness while dehydrator candying produces a firmer, less moist treat.

Impact on Flavor: Candying vs Dehydrator Candying

Candying preserves the natural sugars in fruits, enhancing their flavor through the infusion of syrup, which intensifies sweetness and adds a rich, glossy texture. Dehydrator candying, on the other hand, reduces moisture by slow drying, concentrating the fruit's inherent flavors without adding extra sweetness.

The impact on flavor differs significantly between the two methods; candying imparts a sugary coating that alters the fruit's taste and mouthfeel, creating a contrast between the soft interior and the crystallized exterior. Dehydrator candying maintains a more authentic, concentrated fruit flavor by evaporating water content, resulting in a chewier texture. This method is preferred for those seeking a less sweet but intensely fruity snack, as it avoids the additional sugars used in traditional candying.

Texture Outcomes: Chewy vs Crisp

Candying preserves moisture within fruits, resulting in a chewy texture favored in confections like glazed cherries and citrus peels. This method enhances flavor absorption while maintaining softness.

Dehydrator candying removes more moisture, producing a crisp texture ideal for snacks such as dried apple slices or mango strips. The reduced water content extends shelf life and intensifies natural sweetness.

Sugar Concentration and Preservation

Candied fruits retain moisture through high sugar concentration, creating a hypertonic environment that inhibits microbial growth. Dehydrator candying reduces moisture by drying, which extends preservation but alters texture differently than traditional candying.

- Sugar concentration - Traditional candying relies on saturating fruit with concentrated sugar syrup to control moisture and prevent spoilage.

- Moisture reduction - Dehydrator candying removes water content mechanically, lowering moisture to preserve the fruit without relying solely on sugar.

- Preservation impact - Sugar-rich environments in candying prolong shelf life by osmotic pressure, whereas dehydrator methods rely on water activity reduction for microbial inhibition.

Time Efficiency: Which Method Wins?

| Method | Time Efficiency | Moisture Control |

|---|---|---|

| Candying | Typically requires several days to weeks due to gradual sugar infusion. | Creates a stable, moist texture by replacing water with sugar, preventing microbial growth. |

| Dehydrator Candying | Reduces process time to hours by combining heat and airflow for faster drying and sugar absorption. | Achieves moisture reduction more rapidly but may lead to slightly drier final products if not monitored carefully. |

Equipment and Ingredients Needed

Candying requires fresh fruits, sugar, water, and a heavy saucepan for simmering to infuse sugar into the fruit's moisture. Essential equipment includes a candy thermometer and mesh drying racks for even drying during the slow cooking process.

Dehydrator candying utilizes a food dehydrator to remove moisture from fruit slices with consistent low temperature airflow, using little to no added sugar. Key ingredients remain fresh fruit, but the equipment shifts focus to the dehydrator tray and controlled temperature settings for optimal moisture control.

Best Foods for Each Candying Method

Candied fruits like citrus peels and cherries retain vibrant flavor and moisture when using traditional candying methods, making them ideal for preserving sweetness and texture. Dehydrator candying excels with denser fruits such as apples, pears, and pineapples by efficiently removing moisture while maintaining structural integrity. Choosing the best foods depends on fruit density and moisture content, with softer fruits favoring conventional candying and firmer varieties suiting dehydrator techniques for optimal texture and shelf life.

Related Important Terms

Osmotic Dehydration Candying

Osmotic dehydration candying uses a high-concentration sugar solution to draw moisture out of fruit, preserving texture and enhancing sweetness while preventing excessive drying compared to traditional dehydrator candying. This method maintains optimal moisture levels, resulting in a tender, flavorful product with improved shelf life and reduced risk of crystallization.

Vacuum Candy Infusion

Vacuum candy infusion enhances candying by using low pressure to improve moisture control, enabling better absorption of sugar syrups compared to traditional dehydrator candying methods. This technique preserves texture and flavor more effectively, reducing drying time while maintaining optimal moisture levels within the candy.

Controlled Water Activity (Aw) Candying

Controlled water activity (Aw) candying precisely regulates moisture levels by maintaining specific Aw values, ensuring optimal texture, shelf life, and microbial stability in candied products. Unlike dehydration, which removes moisture indiscriminately, controlled Aw candying preserves moisture balance, enhancing flavor retention and preventing excessive brittleness in the final product.

Low-Temp Dehydrator Candying

Low-temp dehydrator candying preserves the natural texture and vibrant color of fruits by gently removing moisture at controlled temperatures between 120degF and 140degF, minimizing nutrient loss compared to traditional candying methods. This process enhances flavor concentration while maintaining firmness, resulting in superior moisture control and extended shelf life without the addition of excessive sugars or preservatives.

Rapid Dehydrator Caramelization

Rapid dehydrator caramelization enhances moisture control by quickly evaporating water content while promoting the Maillard reaction, resulting in a crispier texture compared to traditional candying methods. This process reduces sugar crystallization and improves shelf-life by creating a uniform, glassy surface that locks in flavor and extends freshness.

Sugar Matrix Encapsulation

Candying preserves moisture by forming a sugar matrix encapsulation around the fruit, which reduces water activity and inhibits microbial growth, maintaining texture and flavor. Dehydrator candying removes moisture through controlled drying but lacks the protective sugar matrix, often resulting in firmer, less juicy products with different shelf-life characteristics.

Microcrystalline Candy Coating

Microcrystalline candy coating offers superior moisture control compared to traditional candying and dehydrator candying by creating a dense, low-permeability barrier that prevents water migration and preserves texture. This advanced coating technology enhances shelf life and maintains product quality by effectively regulating internal moisture levels during storage.

Dynamic Moisture Equilibrium

Candying relies on sugar's ability to bind water and establish a dynamic moisture equilibrium, effectively preserving fruit texture by maintaining stable moisture levels. Dehydrator candying reduces moisture content through controlled drying, but may disrupt the dynamic moisture balance, potentially leading to harder textures and less moisture retention.

Infrared-Assisted Candying

Infrared-assisted candying enhances moisture control by using targeted infrared radiation to rapidly and evenly remove water content, preserving texture and flavor better than traditional dehydrator candying methods. This advanced technique reduces drying time and energy consumption while maintaining optimal product quality through precise thermal regulation.

Candying vs Dehydrator Candying for moisture control. Infographic

cookingdiff.com

cookingdiff.com