When candying, choosing between a metal tray and a non-stick sheet tray impacts the cooking process and final texture. Metal trays conduct heat evenly, promoting consistent caramelization, while non-stick sheet trays prevent sticking and make cleanup easier but may heat less uniformly. For optimal candying results, metal trays are preferred for precise temperature control, whereas non-stick trays offer convenience and reduce the risk of burning.

Table of Comparison

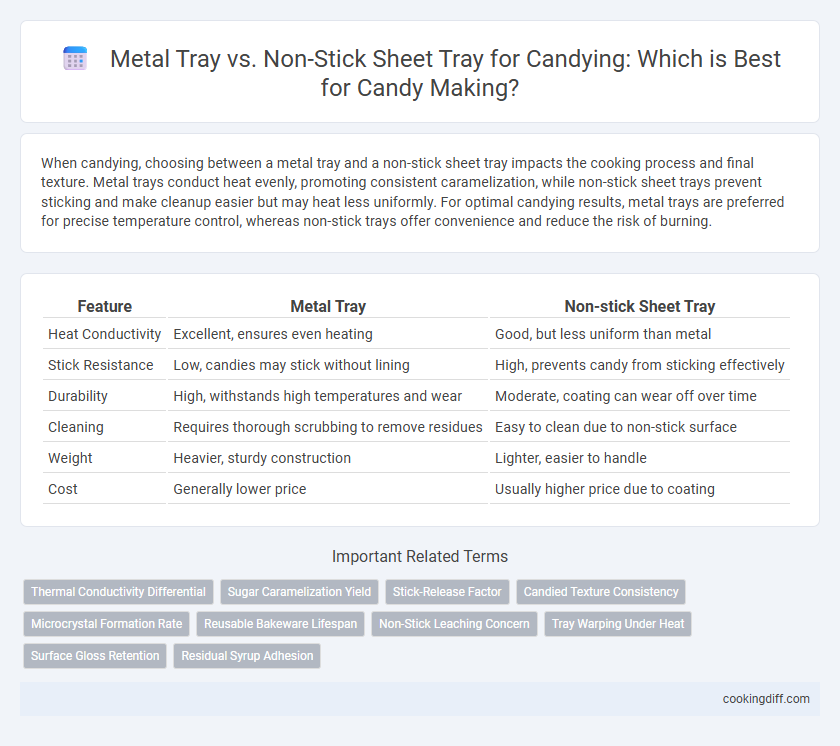

| Feature | Metal Tray | Non-stick Sheet Tray |

|---|---|---|

| Heat Conductivity | Excellent, ensures even heating | Good, but less uniform than metal |

| Stick Resistance | Low, candies may stick without lining | High, prevents candy from sticking effectively |

| Durability | High, withstands high temperatures and wear | Moderate, coating can wear off over time |

| Cleaning | Requires thorough scrubbing to remove residues | Easy to clean due to non-stick surface |

| Weight | Heavier, sturdy construction | Lighter, easier to handle |

| Cost | Generally lower price | Usually higher price due to coating |

Introduction to Candying: Importance of Tray Selection

Choosing the right tray is crucial in candying, as it directly impacts heat distribution and candy texture. Metal trays conduct heat evenly, while non-stick sheet trays prevent sticking and ease cleanup.

- Metal trays ensure uniform heating - This helps achieve consistent candy results by preventing hot spots.

- Non-stick trays simplify candy removal - Their surface reduces the risk of candy adhering and breaking.

- Tray material affects candy appearance - Metal trays may produce crisper edges compared to non-stick options.

Selecting between metal and non-stick sheet trays enhances efficiency and candy quality in the candying process.

Overview: Metal Trays and Non-Stick Sheet Trays

| Metal trays provide excellent heat conduction, ensuring even cooking and precise temperature control for candying processes. |

| Non-stick sheet trays reduce the risk of candy sticking to surfaces, allowing for easier cleanup and preserving the candy's appearance. |

| Choosing between metal and non-stick trays depends on the candy type, cooking method, and desired ease of maintenance during candy preparation. |

Heat Distribution and Candy Consistency

Metal trays offer superior heat distribution due to their high thermal conductivity, which ensures even cooking and prevents hot spots during the candying process. This consistent heat flow helps achieve uniform candy texture and reduces the risk of burning or undercooking.

Non-stick sheet trays provide ease of release but often have less efficient heat transfer, leading to uneven cooking temperatures across the candy surface. This variability can result in inconsistent candy hardness and texture, affecting overall candy quality.

Sticking Issues: Comparing Tray Surfaces

Metal trays often cause sticking issues during candying due to their porous surface, which can trap sugary residues and make removal difficult. Non-stick sheet trays provide a smoother surface, significantly reducing the risk of candies adhering and breaking apart.

Heat conductivity also differs, with metal trays heating candies more evenly but increasing sticking if not properly greased. Non-stick trays offer easier cleanup and better candy release, making them a preferred choice for delicate confectionery processes.

Cleaning and Maintenance: Which Tray Wins?

Metal trays often require scrubbing to remove sticky residue but can withstand abrasive cleaning tools without damage. Non-stick sheet trays allow for easier cleaning with gentle wiping, preserving their coating and preventing rust.

- Durability - Metal trays tolerate harsh scrubbing, making them suitable for deep cleaning without surface damage.

- Cleaning Ease - Non-stick sheet trays require minimal effort to clean due to their smooth, non-porous coating.

- Maintenance - Metal trays need thorough drying to prevent rust, while non-stick trays demand careful handling to avoid coating scratches.

Durability and Longevity in the Candying Process

Metal trays offer superior durability and can withstand high temperatures repeatedly without warping, making them ideal for the candying process. Non-stick sheet trays provide ease of release but tend to degrade faster over time due to coating wear and exposure to acidic ingredients.

- Metal trays maintain structural integrity - They resist bending and corrosion during repeated heating cycles in candying.

- Non-stick coatings deteriorate - Frequent use and contact with sugary substances reduce their lifespan.

- Metal trays deliver long-term value - Their robust construction supports many candying sessions without replacement.

Health and Safety Considerations

Which tray type is safer for candying, metal trays or non-stick sheet trays? Metal trays, made from stainless steel or aluminum, are generally considered safer as they withstand high temperatures without releasing harmful chemicals. Non-stick sheet trays can degrade under extreme heat, potentially leaching toxic substances, posing health risks during candying processes.

Cost Effectiveness: Metal vs Non-Stick Trays

Metal trays offer superior heat conductivity and durability, making them a cost-effective option for candying in the long term despite a higher initial investment. Non-stick sheet trays require less maintenance and reduce sticking issues, but may degrade faster and necessitate frequent replacement costs.

When calculating overall cost efficiency, metal trays provide better value due to their longevity and even heat distribution crucial for consistent candy quality. Non-stick trays might save time cleaning and prevent candy damage, but their shorter lifespan increases replacement frequency and cumulative expenses. Choosing the right tray depends on production volume and maintenance priorities in candying operations.

User Experience: Handling and Practical Tips

Metal trays provide sturdy support and even heat distribution, which helps prevent candy from burning or sticking, making them ideal for consistent candying results. Non-stick sheet trays are easier to clean and allow for effortless candy release, reducing frustration during handling and post-cooking cleanup. Users should lightly grease metal trays for easier candy removal, while non-stick trays typically require minimal preparation, enhancing convenience in the candying process.

Related Important Terms

Thermal Conductivity Differential

Metal trays exhibit higher thermal conductivity than non-stick sheet trays, enabling faster and more even heat distribution during the candying process. This difference in thermal properties significantly impacts caramelization and crystallization, producing more consistent texture and flavor in candies.

Sugar Caramelization Yield

Metal trays provide superior heat conductivity, resulting in a more uniform sugar caramelization yield during candying, while non-stick sheet trays may lead to uneven heat distribution and inconsistent caramelization. The enhanced thermal transfer of metal trays promotes optimal sugar melting and browning, crucial for achieving high-quality caramelized candy textures.

Stick-Release Factor

Metal trays provide excellent heat conductivity for even candying but often require thorough greasing to prevent sticking, as their surface tends to bond with sugary mixtures. Non-stick sheet trays, coated with silicone or similar materials, significantly enhance the stick-release factor, allowing candies to lift easily without residue or damage.

Candied Texture Consistency

Metal trays provide superior heat conduction, ensuring even caramelization and consistent texture in candying, while non-stick sheet trays can cause uneven cooking and softer, less uniform candy surfaces due to their lower thermal conductivity. Choosing metal trays enhances crispness and prevents sticky, overly moist spots, resulting in a more reliable and professional candy texture.

Microcrystal Formation Rate

Metal trays promote faster microcrystal formation during candying due to superior heat conduction, resulting in a crispier texture. Non-stick sheet trays slow cooling rates, reducing microcrystal growth and yielding a softer, chewier candy consistency.

Reusable Bakeware Lifespan

Metal trays offer superior durability and maintain structural integrity under high temperatures, ensuring a longer lifespan for continuous candying processes. Non-stick sheet trays provide ease of release but often degrade faster due to coating wear, reducing their effective reuse cycles in candying applications.

Non-Stick Leaching Concern

Non-stick sheet trays pose a risk of chemical leaching at high temperatures during candying, potentially contaminating the candy with harmful substances like perfluorooctanoic acid (PFOA). Metal trays, typically made from stainless steel or aluminum, offer a safer alternative by resisting leaching and maintaining structural integrity under intense heat.

Tray Warping Under Heat

Metal trays tend to warp under high heat during the candying process due to uneven expansion, compromising candy shape and consistency. Non-stick sheet trays are designed with heat-resistant materials that maintain flatness and durability, ensuring even cooking and superior candy quality.

Surface Gloss Retention

Metal trays provide superior surface gloss retention for candying due to their even heat distribution and minimal reactive properties, which prevent surface discoloration. Non-stick sheet trays may cause uneven gloss and potential surface dulling as their coatings can interfere with the candy's caramelization process.

Metal Tray vs Non-stick Sheet Tray for candying. Infographic

cookingdiff.com

cookingdiff.com