A paring knife offers precise control and a sharp edge ideal for intricate candying tasks like peeling and shaping small ingredients. Ceramic coated utility knives provide durability and resistance to corrosion, making them suitable for handling sticky or sugary substances without dulling quickly. Choosing between the two depends on the level of detail required and the frequency of exposure to abrasive candying elements.

Table of Comparison

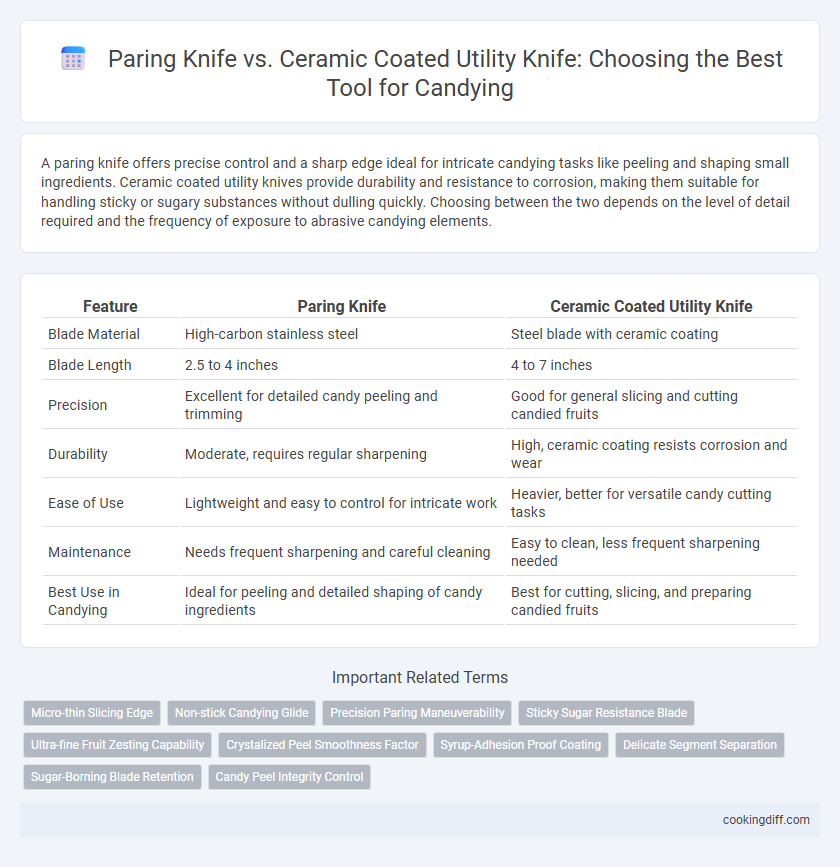

| Feature | Paring Knife | Ceramic Coated Utility Knife |

|---|---|---|

| Blade Material | High-carbon stainless steel | Steel blade with ceramic coating |

| Blade Length | 2.5 to 4 inches | 4 to 7 inches |

| Precision | Excellent for detailed candy peeling and trimming | Good for general slicing and cutting candied fruits |

| Durability | Moderate, requires regular sharpening | High, ceramic coating resists corrosion and wear |

| Ease of Use | Lightweight and easy to control for intricate work | Heavier, better for versatile candy cutting tasks |

| Maintenance | Needs frequent sharpening and careful cleaning | Easy to clean, less frequent sharpening needed |

| Best Use in Candying | Ideal for peeling and detailed shaping of candy ingredients | Best for cutting, slicing, and preparing candied fruits |

Introduction to Candying: Essential Tools

Paring knives and ceramic-coated utility knives are essential tools in the candying process for precise peeling and slicing. Paring knives offer sharp, maneuverable blades ideal for detailed work on fruits and zest, while ceramic-coated utility knives provide durability and resistance to staining from sugary ingredients. Choosing the right knife enhances efficiency and ensures clean cuts, critical for achieving perfect candy texture and presentation.

Paring Knife: Classic Choice for Candying

| Paring Knife: Classic Choice for Candying |

| The paring knife, with its sharp, pointed blade typically 2.5 to 4 inches long, offers precision and control essential for candying tasks like peeling citrus zest or segmenting fruit. Its carbon steel or stainless steel construction ensures durability and maintains sharpness through repeated candying processes. The ergonomic handle design reduces hand fatigue during intricate candy preparation, making it a reliable tool compared to ceramic coated utility knives, which tend to chip under heavy use. |

Ceramic Coated Utility Knife: Modern Innovation

The ceramic coated utility knife offers superior precision and durability for candying tasks, resisting corrosion and maintaining sharpness longer than traditional paring knives. Its non-stick ceramic surface prevents sugary residue buildup, making slicing through candied fruits and nuts cleaner and more efficient.

Modern innovation in ceramic coatings enhances blade strength and reduces friction, allowing smoother cuts crucial for delicate candy preparations. Compared to paring knives, the ceramic coated utility knife combines advanced materials with ergonomic design, optimizing control and reducing hand fatigue during extended use.

Comparing Blade Materials: Steel vs Ceramic Coating

Paring knives typically feature high-carbon stainless steel blades known for their sharpness, durability, and ease of re-sharpening, which is essential for the precision required in candying tasks. In contrast, ceramic coated utility knives offer a non-reactive, corrosion-resistant surface that maintains sharpness longer but may chip more easily during tough cutting jobs.

Steel blades provide better flexibility and toughness when peeling or slicing sugary fruits, while ceramic coatings excel in preventing sticky residue buildup and ensuring a cleaner cut. Choosing between the two depends on the balance between blade resilience and maintenance simplicity for efficient candying preparation.

Precision Cutting: Which Knife Excels in Candying?

Paring knives offer superior precision cutting for candying tasks due to their sharp, narrow blades that easily maneuver around intricate shapes and small fruit pieces. Ceramic coated utility knives provide excellent edge retention and smooth slicing but may lack the delicate control needed for detailed cuts in candy preparation. For achieving fine detail and clean edges in candying, the paring knife excels in precision cutting.

Durability and Maintenance Considerations

Which knife offers better durability and easier maintenance for candying, a paring knife or a ceramic coated utility knife? Paring knives, typically made from stainless steel, provide reliable durability and can withstand frequent sharpening without damage. Ceramic coated utility knives require careful handling to avoid chipping and may need gentler cleaning methods to maintain their coating and sharpness over time.

Safety and Comfort During Prolonged Candying Tasks

Paring knives offer precise control and a comfortable grip, reducing hand fatigue during extended candying sessions. Ceramic coated utility knives provide a smooth cutting experience with less resistance, enhancing safety by minimizing slips.

- Ergonomic Handle - Paring knives often feature ergonomically shaped handles designed for prolonged use, promoting comfort and reducing strain.

- Non-Slip Surface - Ceramic coatings on utility knives create a slick surface that helps prevent sticking to sticky candy mixtures, improving safety.

- Blade Flexibility - Paring knives typically have more flexible blades that allow for finer, controlled cuts essential in candying.

Choosing a knife that balances a secure grip with sharp, smooth cutting surfaces ensures safety and comfort throughout candy preparation.

Impact on Ingredient Texture and Presentation

The choice between a paring knife and a ceramic coated utility knife greatly affects the texture and presentation of candied ingredients. Paring knives offer precise control for delicate cuts, preserving ingredient integrity, while ceramic coated utility knives provide smoother slicing, minimizing moisture loss and discoloration.

- Paring Knife Precision - Enables intricate cuts that maintain the firmness and shape of candied fruits or vegetables.

- Ceramic Coating Smoothness - Reduces friction, resulting in cleaner slices that enhance visual appeal and texture consistency.

- Ingredient Preservation - Both knives impact ingredient quality differently, with paring knives preserving natural texture and ceramic coatings improving surface finish.

Price and Value Analysis for Home Candy Makers

Paring knives generally offer a lower price point, making them an accessible choice for home candy makers seeking basic precision cutting without a large investment. Ceramic coated utility knives come at a higher cost but provide enhanced durability and superior resistance to sticky candy residues, offering better long-term value.

For home candy makers prioritizing budget, paring knives deliver sufficient performance for tasks like peeling and slicing candied fruits. Ceramic coated utility knives, though pricier, reduce maintenance effort and retain sharpness longer, which can justify their premium cost in frequent candying projects. Evaluating how often and precisely the knife will be used is key to determining the most cost-effective option for candy preparation.

Related Important Terms

Micro-thin Slicing Edge

A paring knife offers a precise micro-thin slicing edge ideal for delicate candying tasks, enabling clean cuts without crushing fragile sugar coatings. Ceramic coated utility knives provide sharpness and durability, but their slightly thicker edges may compromise the finesse needed for perfect candy slicing.

Non-stick Candying Glide

A ceramic coated utility knife offers superior non-stick properties compared to a paring knife, ensuring smooth candying glide and precise cuts without residue buildup. Its durable ceramic surface resists caramel and sugar adhesion, making it ideal for delicate candy preparation.

Precision Paring Maneuverability

Paring knives offer superior precision and maneuverability for candying tasks that require intricate cuts and detailed work, ensuring delicate candy pieces are shaped accurately. Ceramic coated utility knives provide a sharper edge and enhanced durability but may sacrifice the fine control needed for the delicate slicing and peeling involved in candying.

Sticky Sugar Resistance Blade

Paring knives with high-carbon stainless steel blades offer excellent stick resistance when handling sticky sugar during candying, providing precise control for intricate tasks. Ceramic coated utility knives enhance non-stick properties, reducing sugar adhesion and making cleanup easier, while maintaining sharpness for efficient slicing.

Ultra-fine Fruit Zesting Capability

Paring knives offer exceptional control and precision for ultra-fine fruit zesting during candying, allowing for delicate and uniform zest extraction that enhances flavor infusion. Ceramic coated utility knives maintain sharpness longer and resist acid corrosion, but their broader blade may lack the finesse needed for intricate zest work.

Crystalized Peel Smoothness Factor

A paring knife with its sharp, steel blade allows precise control and clean cuts essential for achieving the optimal smoothness in crystallized peel during candying. Ceramic coated utility knives offer excellent edge retention but may lack the fine tip precision, potentially affecting the delicate texture and smooth finish of the peel.

Syrup-Adhesion Proof Coating

A ceramic coated utility knife with syrup-adhesion proof coating prevents sticky residue buildup during candying, ensuring smoother and more efficient slicing of sticky confections. Paring knives lack this specialized coating, leading to frequent syrup clinging and reduced cutting precision in candy preparation.

Delicate Segment Separation

A paring knife offers precise control and a sharp, thin blade ideal for delicate segment separation in candying, minimizing damage to citrus or fruit pieces. Ceramic-coated utility knives provide durability and resistance to staining but may lack the fine edge needed for intricate candy segmenting tasks.

Sugar-Borning Blade Retention

Paring knives with high-carbon steel blades offer superior sugar-borning blade retention, maintaining sharpness despite frequent contact with sticky, crystallizing sugar surfaces. Ceramic coated utility knives resist sugar buildup and corrosion while preserving edge integrity longer, making them ideal for precise candying tasks requiring sustained sharpness.

Paring Knife vs Ceramic Coated Utility Knife for candying. Infographic

cookingdiff.com

cookingdiff.com