Choosing between a stainless ladle and a porcelain dipper for candying depends on heat conductivity and safety. Stainless steel ladles offer excellent heat resistance and durability, ensuring even candy coating without risk of cracking under high temperatures. Porcelain dippers provide a non-reactive surface ideal for delicate batches but require careful handling to avoid breakage.

Table of Comparison

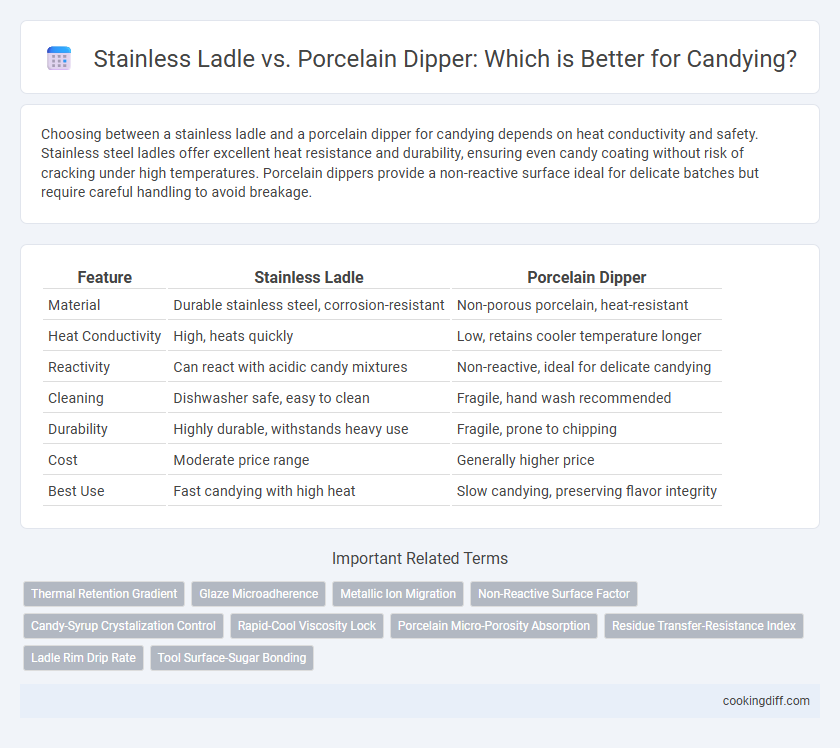

| Feature | Stainless Ladle | Porcelain Dipper |

|---|---|---|

| Material | Durable stainless steel, corrosion-resistant | Non-porous porcelain, heat-resistant |

| Heat Conductivity | High, heats quickly | Low, retains cooler temperature longer |

| Reactivity | Can react with acidic candy mixtures | Non-reactive, ideal for delicate candying |

| Cleaning | Dishwasher safe, easy to clean | Fragile, hand wash recommended |

| Durability | Highly durable, withstands heavy use | Fragile, prone to chipping |

| Cost | Moderate price range | Generally higher price |

| Best Use | Fast candying with high heat | Slow candying, preserving flavor integrity |

Introduction: The Importance of Proper Tools in Candying

Using the right tools in candying ensures consistent texture and flavor by maintaining precise temperature control and preventing contamination. Stainless ladles offer durability and heat resistance, while porcelain dippers provide non-reactive surfaces ideal for delicate sugar syrups.

Selecting between a stainless ladle and a porcelain dipper depends on the candy type and the desired outcome, as material properties affect heat distribution and cleanup ease. Proper tools enhance efficiency and preserve the quality of homemade candies, making the candying process more reliable.

Material Overview: Stainless Ladle vs Porcelain Dipper

Stainless ladles are made from durable, corrosion-resistant metal, providing excellent heat conductivity and long-lasting use in candying processes. Their non-porous surface prevents flavor absorption, ensuring a pure taste when handling various sugar syrups.

Porcelain dippers, crafted from ceramic material, offer excellent heat retention and a smooth, inert surface that resists staining and chemical reactions with acidic candy ingredients. However, they are more fragile and can chip or crack under high temperatures compared to stainless ladles.

Heat Conductivity: Which Performs Better for Candying?

Stainless steel ladles offer superior heat conductivity, allowing for even and rapid heating essential in candying processes. Porcelain dippers, while aesthetically pleasing and resistant to staining, have lower thermal conductivity, which can result in uneven temperature distribution. For precise temperature control and efficient candying, stainless steel ladles perform better than porcelain dippers.

Durability and Longevity: Stainless vs Porcelain

Which material offers better durability and longevity for candying, stainless steel or porcelain? Stainless steel ladles resist chipping, cracking, and high temperatures, ensuring extended usability in hot sugar mixtures. Porcelain dippers, while heat resistant, are more prone to breakage and wear over time, making stainless steel the preferred choice for long-lasting candying tools.

Ease of Cleaning and Maintenance

Stainless ladles offer superior ease of cleaning due to their non-porous surface, resisting sugar residue buildup and allowing for quick rinsing and scrubbing. Porcelain dippers, while aesthetically pleasing, can retain sticky residues in microscopic cracks, making thorough cleaning more labor-intensive and increasing maintenance time. Stainless steel's durability also minimizes the risk of chipping, unlike porcelain, which requires careful handling to prevent damage during cleaning.

Reactivity with Sugar and Ingredients

Stainless ladles are non-reactive, making them ideal for handling hot sugar mixtures without altering the flavor or color of the candy. Porcelain dippers, while also non-reactive, are prone to chipping and heat retention issues that can affect candy consistency.

Stainless steel resists acidic ingredients commonly used in candying, preventing metallic taste and contamination. Porcelain, although inert, may absorb flavors over time if not properly glazed, risking cross-contamination between batches. Choosing stainless ladles ensures durability and purity in handling crystalline sugar solutions and syrups.

Comfort and Safety: Handle Design and Grip

| Stainless Ladle | Ergonomically designed handles provide a firm, secure grip reducing hand strain during extended use, with heat-resistant properties ensuring safe handling when candying hot sugar. |

| Porcelain Dipper | Handles often lack ergonomic shaping, making prolonged use less comfortable and increasing slip risk; however, porcelain's non-conductive nature offers excellent heat insulation for safer grip despite the lack of texture. |

Aesthetics and Presentation in the Kitchen

Stainless ladles offer a sleek, modern look ideal for contemporary kitchen aesthetics, while porcelain dippers provide a classic, elegant touch suited for traditional candying setups. Both tools enhance presentation but cater to different stylistic preferences in candy making.

- Stainless ladle's reflective surface - adds a professional shine and highlights the glossy texture of candies.

- Porcelain dipper's smooth matte finish - complements colorful, delicate confections with understated sophistication.

- Material contrast - influences the visual appeal and perceived quality of the candying process.

Choosing the right tool enhances the visual impact and aligns with the kitchen's overall design theme.

Cost Comparison: Value for Your Investment

Stainless ladles generally offer better durability and longevity compared to porcelain dippers, making them a cost-effective option for frequent candying. Porcelain dippers, while cheaper upfront, may require more frequent replacements due to chipping or cracking during use.

- Initial Cost - Porcelain dippers are more affordable initially but lack long-term resilience.

- Durability - Stainless ladles resist wear and corrosion, providing lasting value in candy production.

- Maintenance - Stainless ladles are easier to clean and maintain, reducing overall operational expenses.

Related Important Terms

Thermal Retention Gradient

Stainless ladles offer superior thermal retention due to their high thermal conductivity and durable metal structure, ensuring consistent temperature control vital for candying syrup precision. Porcelain dippers exhibit slower heat transfer with a lower thermal retention gradient, which can lead to uneven temperature distribution and less effective candying results.

Glaze Microadherence

Stainless ladles provide superior glaze microadherence due to their smooth, non-porous surface that prevents sugar crystals from sticking and promotes even coating during candying. Porcelain dippers, while resistant to high temperatures, tend to have microscopic surface irregularities that increase glaze retention but risk uneven application and potential cracking under thermal stress.

Metallic Ion Migration

Stainless steel ladles are preferred for candying due to their resistance to metallic ion migration, which prevents unwanted flavors or contamination in sugary syrups. Porcelain dippers, while inert and non-reactive, risk chipping and introducing ceramic particles, making stainless steel the safer choice for maintaining purity during candying.

Non-Reactive Surface Factor

Stainless ladles offer a non-reactive surface that prevents flavor alteration and chemical reactions during candying, maintaining ingredient purity and consistent taste. Porcelain dippers also provide a non-reactive surface but are more fragile and prone to chipping, which can introduce contaminants and limit durability in high-temperature candying processes.

Candy-Syrup Crystalization Control

Stainless ladles offer superior heat conductivity and durability, allowing precise control over candy-syrup crystallization by maintaining consistent temperatures during the candying process. Porcelain dippers, while non-reactive and easy to clean, lack the thermal responsiveness of stainless, increasing the risk of uneven cooling and unwanted crystal formation in syrup.

Rapid-Cool Viscosity Lock

Stainless ladles offer superior thermal conductivity that enhances rapid-cool viscosity lock essential in candying, preventing crystallization by quickly stabilizing sugar syrup temperature. Porcelain dippers, while aesthetically pleasing and non-reactive, lack efficient heat transfer, making them less effective for maintaining the precise viscosity required during rapid cooling and candy formation.

Porcelain Micro-Porosity Absorption

Porcelain dippers offer superior micro-porosity absorption compared to stainless ladles, allowing them to retain and distribute heat more evenly during the candying process, which prevents sugar crystallization and ensures a smooth coating. This micro-porosity also reduces the likelihood of caramel sticking, making porcelain an ideal material for precise temperature control and texture in candy production.

Residue Transfer-Resistance Index

Stainless ladles exhibit a higher Residue Transfer-Resistance Index due to their smooth, non-porous surface that prevents sugar and syrup adherence during candying, ensuring cleaner transfers and less cross-contamination. In contrast, porcelain dippers, while heat-resistant, have a porous texture that retains sticky residues, increasing the risk of flavor contamination and requiring more rigorous cleaning to maintain purity in candy production.

Ladle Rim Drip Rate

Stainless ladles exhibit a lower rim drip rate compared to porcelain dippers due to their smooth, non-porous surface, which minimizes candy syrup adhering to the rim and reduces wastage. The durable stainless steel material also provides better heat transfer control, ensuring consistent candy portions without excessive dripping.

Stainless Ladle vs Porcelain Dipper for Candying. Infographic

cookingdiff.com

cookingdiff.com