Candying involves immersing fruits in increasingly concentrated sugar syrups to replace water content with sugar, resulting in a chewy, sweet product. Osmo-dehydration, by contrast, uses osmotic pressure differences to draw out water and infuse sugar simultaneously, preserving more of the fruit's original texture and flavor. Both methods sweeten fruits effectively, but candying produces a denser, more syrup-saturated result, while osmo-dehydration offers a lighter, less processed alternative.

Table of Comparison

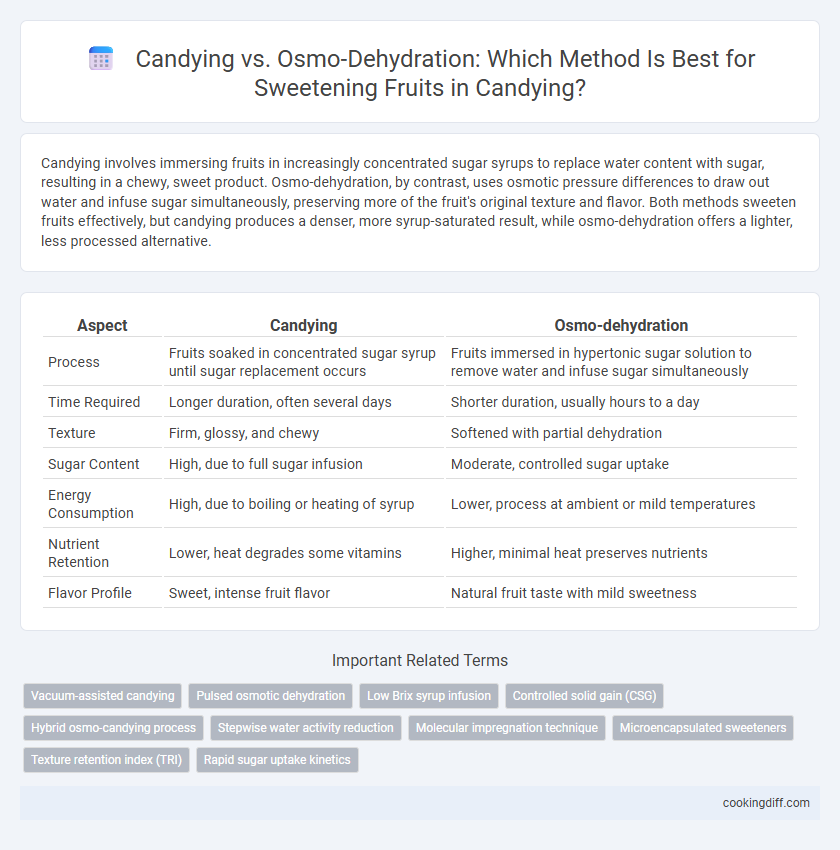

| Aspect | Candying | Osmo-dehydration |

|---|---|---|

| Process | Fruits soaked in concentrated sugar syrup until sugar replacement occurs | Fruits immersed in hypertonic sugar solution to remove water and infuse sugar simultaneously |

| Time Required | Longer duration, often several days | Shorter duration, usually hours to a day |

| Texture | Firm, glossy, and chewy | Softened with partial dehydration |

| Sugar Content | High, due to full sugar infusion | Moderate, controlled sugar uptake |

| Energy Consumption | High, due to boiling or heating of syrup | Lower, process at ambient or mild temperatures |

| Nutrient Retention | Lower, heat degrades some vitamins | Higher, minimal heat preserves nutrients |

| Flavor Profile | Sweet, intense fruit flavor | Natural fruit taste with mild sweetness |

Introduction: Candying vs Osmo-Dehydration

What distinguishes candying from osmo-dehydration in the process of sweetening fruits? Candying involves immersing fruits in concentrated sugar syrup to replace water content with sugar, resulting in a glossy, sweet product with extended shelf life. Osmo-dehydration uses osmotic pressure differences to partially remove water from fruits by soaking them in hypertonic sugar solutions, enhancing sweetness while maintaining more of the fruit's original texture and flavor.

Defining Candying: Traditional Sweetening Process

Candying is a traditional sweetening process that involves soaking fruits in concentrated sugar syrup until they become saturated with sugar, preserving their texture and flavor. This technique enhances the fruit's shelf life while maintaining a chewy consistency and vibrant color. Unlike osmo-dehydration, candying fully immerses fruits in syrup rather than using osmotic pressure to extract water, resulting in a distinctly sweet and dense product.

Understanding Osmo-Dehydration: A Modern Alternative

Osmo-dehydration is a modern fruit preservation technique that uses osmotic pressure to remove water content while infusing natural sugars, enhancing sweetness without the intense syrup immersion used in candying. This method maintains fruit texture and nutritional value better than traditional candying, which relies on prolonged boiling in sugar syrup.

Osmo-dehydration involves soaking fruit in a hypertonic sugar solution, causing water to migrate out and sugar to diffuse in, resulting in a balanced sweetness and chewy texture. It reduces processing time and energy consumption compared to candying, aligning with sustainable food production trends. The process also limits microbial growth, extending shelf life while preserving delicate fruit flavors and colors more effectively.

Key Differences in Processing Techniques

Candied fruits undergo a process where fruit is soaked in sugar syrup at varying concentrations, allowing sugar to completely replace water content. Osmo-dehydration uses osmotic pressure by immersing fruit in hypertonic solutions, resulting in partial water loss while retaining some natural texture and flavor.

Candied fruits typically require longer processing times and higher temperature treatments to achieve full sugar saturation. Osmo-dehydration operates at lower temperatures and shorter durations, preserving more nutritional value and color of the fruit compared to candying.

Sugar Penetration: How Each Method Sweetens Fruit

| Method | Sugar Penetration Process | Effect on Fruit Sweetness |

|---|---|---|

| Candying | Sugar syrup diffuses into fruit cells at high concentrations, replacing water and resulting in thick sugar crystallization on the surface. | Produces intense sweetness with a firm, glossy texture and extended shelf life due to concentrated sugar content. |

| Osmo-dehydration | Osmotic pressure drives sugar molecules slowly into fruit tissue while water is drawn out, allowing gradual sugar absorption. | Yields moderately sweetened fruit with preserved natural texture and moisture, maintaining freshness over time. |

Impact on Nutritional Value and Health Aspects

Candying typically involves soaking fruits in high-concentration sugar syrup, which significantly increases sugar content and may reduce vitamin levels. Osmo-dehydration uses osmotic pressure to remove water while retaining more nutrients and lowering sugar absorption, offering a healthier alternative for sweetening fruits.

- Candying increases sugar content - The process leads to a high sugar concentration, posing potential health risks such as increased calorie intake and risk of diabetes.

- Osmo-dehydration preserves nutrients - Compared to candying, it better retains vitamins like vitamin C and antioxidants, maintaining more of the fruit's original nutritional value.

- Health impact varies - Candying may contribute to higher glycemic index, while osmo-dehydrated fruits offer a lower glycemic impact and are more suitable for health-conscious consumers.

Texture and Flavor: Comparing Final Fruit Products

Candying infuses fruit with a dense sugar syrup, resulting in a firmer texture and intensified sweetness, while osmo-dehydration retains more natural fruit moisture, preserving a softer bite and subtle flavor complexity. Flavor profiles from candying tend to be richer and more uniform, whereas osmo-dehydrated fruits offer nuanced, naturally enhanced flavors with less overall sweetness.

- Candying promotes a firm, chewy texture - Sugar crystallization within the fruit maintains its shape and bite.

- Osmo-dehydration preserves natural moisture - This process leads to a softer, more tender fruit texture.

- Flavor intensity varies by method - Candying generates a sweeter, more homogeneous flavor, while osmo-dehydration highlights original fruit notes.

Choosing between candying and osmo-dehydration depends on the desired balance of texture and flavor in the final product.

Shelf Life and Preservation Efficiency

Candying significantly extends the shelf life of fruits by replacing water content with sugar, creating an inhospitable environment for microbial growth. Osmo-dehydration also preserves fruits by partial water removal and sugar infusion but typically results in a shorter shelf life compared to candying.

- Candying - Involves full sugar saturation that preserves fruit texture and flavor over extended periods.

- Osmo-dehydration - Partially removes water and infuses more moderate sugar levels, leading to less preservation efficiency.

- Shelf Life Comparison - Candying can prolong fruit shelf life from months up to a year, while osmo-dehydration maintains freshness for weeks to a few months.

Applications in Culinary and Commercial Settings

Candied fruits retain a glossy texture and intense sweetness, making them ideal for decorative desserts and confectionery products in commercial bakeries. Osmo-dehydration preserves more natural fruit flavors and nutrients while reducing sugar content, favored in health-conscious culinary applications and upscale fruit preserves. Both methods enhance shelf life but cater to distinct market preferences, with candying appealing to traditional sweets and osmo-dehydration to modern, clean-label food products.

Related Important Terms

Vacuum-assisted candying

Vacuum-assisted candying accelerates sugar infusion by lowering pressure to enhance vacuum penetration, resulting in higher sugar uptake and improved texture compared to traditional osmo-dehydration methods. This technique maintains fruit integrity while achieving uniform sweetness and reduced processing time, unlike conventional osmo-dehydration which relies on passive osmotic gradients.

Pulsed osmotic dehydration

Pulsed osmotic dehydration enhances fruit sweetening by intermittently immersing fruits in hypertonic solutions, improving solute diffusion and preserving texture more effectively than traditional candying methods. This technique reduces water content while infusing natural sugars, resulting in sweeter, firmer fruits with lower processing time and energy consumption.

Low Brix syrup infusion

Candying involves immersing fruits in a high Brix syrup, typically above 60%, to achieve maximum sugar infusion and preservation, whereas osmo-dehydration uses lower Brix solutions, around 30-40%, to draw out moisture while moderately increasing sweetness. Low Brix syrup infusion in osmo-dehydration results in less intense sweetness but better retention of fruit texture and natural flavors compared to the heavily saturated candying process.

Controlled solid gain (CSG)

Candying achieves controlled solid gain (CSG) by slowly infusing sugar syrup into fruits, preserving texture and flavor balance, whereas osmo-dehydration utilizes osmotic pressure to partially dehydrate fruits while simultaneously allowing solid gain, often resulting in faster processing but less precise CSG control. Optimizing CSG in candying ensures superior sweetness uniformity and product quality compared to the variable solid uptake in osmo-dehydration methods.

Hybrid osmo-candying process

The hybrid osmo-candying process combines osmo-dehydration and candying techniques, enhancing fruit sweetness by allowing partial sugar infusion while preserving texture and color. This method optimizes sugar absorption and moisture removal, resulting in a higher quality product with improved shelf-life compared to traditional candying or osmo-dehydration alone.

Stepwise water activity reduction

Candying achieves sweetening through stepwise water activity reduction by immersing fruits in progressively concentrated sugar syrups, which gradually replaces water content with sugar, enhancing preservation and flavor. Osmo-dehydration also reduces water activity but relies on osmotic pressure differences using hypertonic solutions, resulting in faster dehydration but typically less uniform sugar infusion compared to candying.

Molecular impregnation technique

Candying uses molecular impregnation to infuse sugar deeply into fruit cells, resulting in enhanced sweetness and preservation, while osmo-dehydration relies on osmotic pressure gradients to partially remove moisture and concentrate sugars. The molecular impregnation technique in candying ensures uniform sugar distribution at a cellular level, improving texture and shelf life compared to the surface-level sweetness achieved by osmo-dehydration.

Microencapsulated sweeteners

Microencapsulated sweeteners enhance candying by providing controlled release and improved stability compared to osmo-dehydration, which relies on water removal and sugar infusion. Candying with microencapsulated sweeteners preserves fruit texture and flavor more effectively while reducing crystallization and extending shelf life.

Texture retention index (TRI)

Candying preserves fruit texture more effectively than osmo-dehydration, achieving a higher Texture Retention Index (TRI) due to the infusion of sugar syrup that maintains cell structure integrity. Osmo-dehydration often results in lower TRI values as water loss causes more significant tissue collapse and softening.

Candying vs Osmo-dehydration for sweetening fruits. Infographic

cookingdiff.com

cookingdiff.com