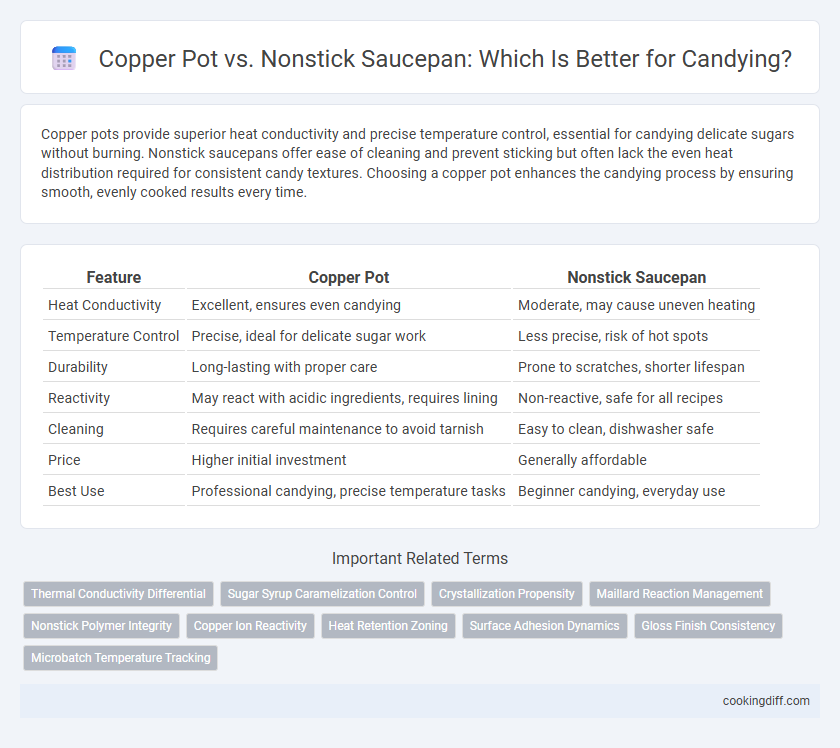

Copper pots provide superior heat conductivity and precise temperature control, essential for candying delicate sugars without burning. Nonstick saucepans offer ease of cleaning and prevent sticking but often lack the even heat distribution required for consistent candy textures. Choosing a copper pot enhances the candying process by ensuring smooth, evenly cooked results every time.

Table of Comparison

| Feature | Copper Pot | Nonstick Saucepan |

|---|---|---|

| Heat Conductivity | Excellent, ensures even candying | Moderate, may cause uneven heating |

| Temperature Control | Precise, ideal for delicate sugar work | Less precise, risk of hot spots |

| Durability | Long-lasting with proper care | Prone to scratches, shorter lifespan |

| Reactivity | May react with acidic ingredients, requires lining | Non-reactive, safe for all recipes |

| Cleaning | Requires careful maintenance to avoid tarnish | Easy to clean, dishwasher safe |

| Price | Higher initial investment | Generally affordable |

| Best Use | Professional candying, precise temperature tasks | Beginner candying, everyday use |

Introduction to Candying: Why Cookware Matters

Copper pots provide superior heat conductivity essential for precise temperature control in candying. Nonstick saucepans offer ease of cleanup but may lack the even heating needed for delicate sugar work.

- Copper Pot Heat Conductivity - Ensures even temperature distribution to prevent hot spots and sugar crystallization.

- Nonstick Surface Convenience - Facilitates easier stirring and reduces sticking during the candying process.

- Durability and Reactivity - Copper reacts minimally with acidic ingredients, maintaining flavor integrity in candy recipes.

Choosing the right cookware directly influences the texture and success of your candied confections.

Understanding Candying: Precision and Technique

Using a copper pot for candying offers superior heat conductivity, allowing precise temperature control essential for sugar crystallization and texture development. Nonstick saucepans provide ease of cleanup but often distribute heat unevenly, increasing the risk of burning or grainy results. Mastering candying demands consistent, accurate heat application, making copper pots the preferred choice for achieving perfect candy texture and quality.

Copper Pots: Traditional Choice for Candying

| Copper Pot: Traditional Choice for Candying |

| Copper pots offer superior heat conductivity, ensuring even temperature distribution necessary for precise candying processes such as making caramel or sugar syrups. Their responsiveness to temperature changes reduces the risk of scorching sugars compared to nonstick saucepans. The natural reactivity of copper enhances flavor development, making it a preferred material in professional and artisanal candy-making. |

Nonstick Saucepans: Modern Convenience

Nonstick saucepans offer easy cleanup and reduce the risk of sugar sticking or burning during candying. Their lightweight design and even heat distribution make them ideal for precise temperature control essential in candy making.

- Easy Cleanup - Nonstick surfaces prevent sugar from hardening on the pan, speeding up post-cooking maintenance.

- Even Heat Distribution - Advanced coatings ensure consistent warmth, critical for smooth candy texture.

- Lightweight Design - Easier to handle than heavier copper pots, improving safety and precision during candying.

Heat Conductivity: Copper Pot vs Nonstick Saucepan

Copper pots offer superior heat conductivity, allowing for even and precise temperature control essential in candying. Nonstick saucepans typically have lower thermal conductivity, resulting in slower and less uniform heating that can cause sugar to crystallize unevenly. The rapid heat response of copper pots reduces the risk of scorching, making them the preferred choice for candy-making techniques requiring careful temperature management.

Temperature Control and Evenness in Candying

Copper pots provide superior temperature control and even heat distribution essential for precise candying, preventing sugar burn and ensuring smooth caramelization. Nonstick saucepans, while easier to clean, often have uneven heating which can cause hot spots and inconsistent candy texture.

- Superior thermal conductivity - Copper pots rapidly adjust to temperature changes, offering unmatched control during candying.

- Even heat distribution - Copper ensures consistent temperature across the saucepan surface, reducing the risk of sugar crystallization.

- Nonstick limitations - Nonstick pans may develop uneven hot spots, leading to burned sugar or lump formation during candying.

Caramelization and Sugar Crystallization

Copper pots offer superior heat conductivity, allowing precise temperature control essential for even caramelization during candying. This minimizes hot spots and reduces the risk of sugar crystallization, ensuring a smooth, glossy finish.

Nonstick saucepans provide easier cleanup but often lack the thermal responsiveness needed for delicate sugar work. Their uneven heat distribution can lead to inconsistent caramelization and increased chances of sugar crystallization.

Cleaning and Maintenance: Copper vs Nonstick

Which is easier to clean and maintain after candying, a copper pot or a nonstick saucepan? Copper pots require regular polishing to prevent tarnishing and maintain their conductivity, making cleaning more labor-intensive. Nonstick saucepans offer effortless cleaning with minimal scrubbing, as their surfaces resist candy residue and stains effectively.

Safety Considerations for Candying Tools

Copper pots provide superior heat conductivity, allowing for precise temperature control crucial in candying, but require regular polishing to prevent reactive surface hazards. Nonstick saucepans reduce the risk of candy sticking and burning, enhancing safety by minimizing the need for excessive stirring and preventing scorching.

However, copper reacts with acidic ingredients, potentially leaching harmful metals if not properly lined, posing a safety concern. Nonstick pans, typically coated with PTFE or ceramic, must be used at recommended temperatures to avoid toxic fumes, ensuring safer candy preparation.

Related Important Terms

Thermal Conductivity Differential

Copper pots offer superior thermal conductivity, ensuring precise and even heat distribution during candying, which prevents hot spots and reduces the risk of burning sugar. Nonstick saucepans typically have lower thermal conductivity, leading to less efficient heat transfer and potential uneven cooking results in candy-making.

Sugar Syrup Caramelization Control

Copper pots offer superior heat conductivity and precise temperature control essential for sugar syrup caramelization, minimizing the risk of hot spots and burning during candying. Nonstick saucepans provide easy cleanup but often deliver uneven heat distribution, potentially compromising the delicate caramelization process required for perfect candy texture.

Crystallization Propensity

Copper pots excel in candying due to their superior heat conductivity, which ensures even temperature distribution and minimizes hot spots, reducing the risk of premature crystallization during sugar cooking. Nonstick saucepans, while easier to clean, often result in uneven heating that can cause inconsistent sugar crystallization, affecting the final texture and quality of the candy.

Maillard Reaction Management

Copper pots provide superior temperature control critical for managing the Maillard reaction during candying, preventing scorching and ensuring even browning; nonstick saucepans, while easy to clean, may not offer the same precision in heat distribution, potentially compromising the quality of caramelization. Optimal Maillard reaction management depends on consistent, responsive heat, making copper cookware the preferred choice for achieving the desired flavor and texture in candying processes.

Nonstick Polymer Integrity

Nonstick saucepans maintain polymer integrity during candying by preventing sugar from adhering and burning, ensuring smooth caramelization without compromising the pan's coating. In contrast, copper pots, while excellent for heat conductivity, may require more care to avoid damaging surfaces, as their lack of nonstick polymer can lead to stubborn residue and difficult cleanup.

Copper Ion Reactivity

Copper pots provide superior heat conductivity and precise temperature control essential for candying, but their reactivity with acidic sugar solutions can cause copper ions to leach into the candy, potentially affecting flavor and safety. Nonstick saucepans prevent such ion transfer due to their inert coatings, offering a more stable cooking environment that preserves the candy's purity and taste.

Heat Retention Zoning

Copper pots offer superior heat retention zoning due to their excellent thermal conductivity, allowing for precise temperature control essential for candying delicate sugar mixtures. Nonstick saucepans typically have uneven heat distribution, which can cause hotspots that risk burning or crystallizing the candy.

Surface Adhesion Dynamics

Copper pots offer superior heat conductivity that ensures even temperature distribution, reducing hotspots and minimizing sugar crystallization during candying. Nonstick saucepans, while preventing direct sticking, may cause uneven heating, leading to inconsistent surface adhesion and potential texture issues in caramel and other sugar confections.

Gloss Finish Consistency

Copper pots offer superior heat conductivity, providing precise temperature control essential for consistent candying results, while their gloss finish ensures even heat distribution and prevents hot spots. Nonstick saucepans, despite easy clean-up, often lack the consistent heat retention of copper, which can compromise the smooth gloss finish critical to expertly candied confections.

Copper Pot vs Nonstick Saucepan for candying. Infographic

cookingdiff.com

cookingdiff.com