Candying nuts involves immersing them in a sugar syrup to infuse sweetness and improve texture, while Instant Controlled Pressure Drop (DIC) Candying uses rapid pressure changes to enhance sugar penetration and reduce processing time. The DIC method preserves the nut's natural flavors and nutritional qualities more effectively by preventing excessive heat exposure. This innovative technique results in a crispier, more uniformly candied nut with improved shelf life compared to traditional candying methods.

Table of Comparison

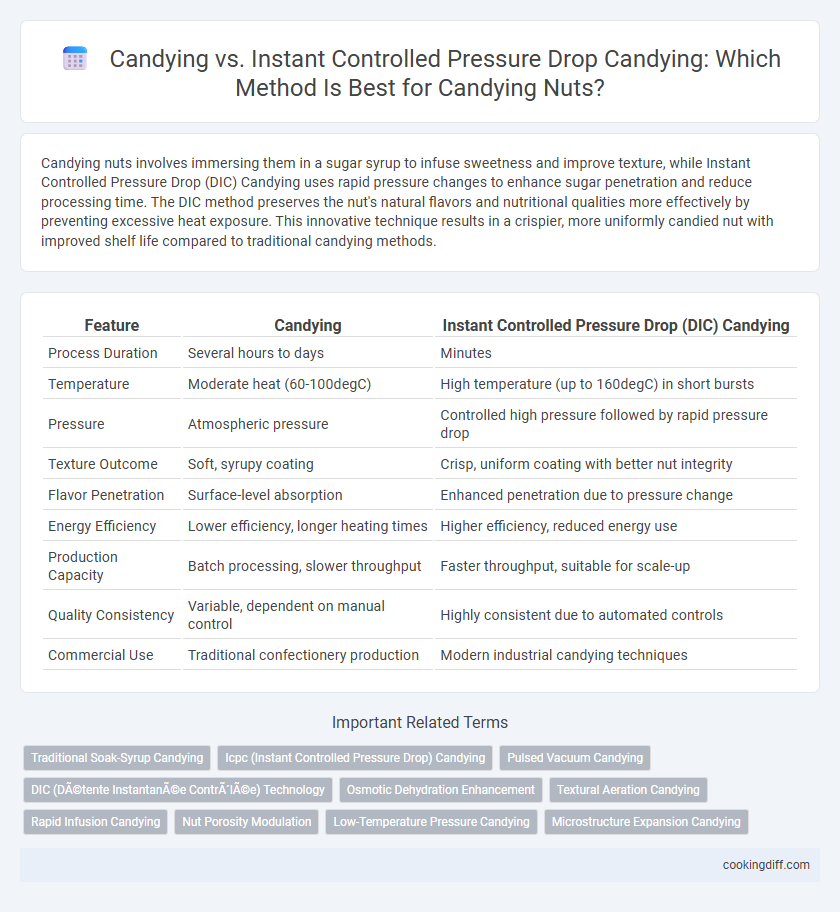

| Feature | Candying | Instant Controlled Pressure Drop (DIC) Candying |

|---|---|---|

| Process Duration | Several hours to days | Minutes |

| Temperature | Moderate heat (60-100degC) | High temperature (up to 160degC) in short bursts |

| Pressure | Atmospheric pressure | Controlled high pressure followed by rapid pressure drop |

| Texture Outcome | Soft, syrupy coating | Crisp, uniform coating with better nut integrity |

| Flavor Penetration | Surface-level absorption | Enhanced penetration due to pressure change |

| Energy Efficiency | Lower efficiency, longer heating times | Higher efficiency, reduced energy use |

| Production Capacity | Batch processing, slower throughput | Faster throughput, suitable for scale-up |

| Quality Consistency | Variable, dependent on manual control | Highly consistent due to automated controls |

| Commercial Use | Traditional confectionery production | Modern industrial candying techniques |

Introduction to Traditional Candying for Nuts

Traditional candying for nuts involves simmering nuts in a sugar syrup over an extended period, allowing the syrup to crystallize and coat the nuts evenly. This method enhances the natural flavor and texture while creating a glossy, sweet exterior. Although effective, traditional candying requires longer processing times and precise temperature control to prevent burning or uneven coating.

Understanding Instant Controlled Pressure Drop (ICPD) Candying

| Candying: A traditional preservation method where nuts are immersed in sugar syrup, allowing gradual infusion while enhancing sweetness and texture through prolonged heating and drying. |

| Instant Controlled Pressure Drop (ICPD) Candying: An advanced process applying rapid pressure drop to nuts after sugar impregnation, causing instantaneous vaporization inside the product that improves sugar diffusion and reduces processing time. |

| Advantages of ICPD: Significantly shorter candying cycles, more uniform sugar distribution, enhanced nut crispness, and minimized thermal degradation compared to conventional candying. |

Historical Evolution of Nut Candying Methods

Traditional nut candying has evolved significantly since its origins, with early methods relying on slow sugar infusion processes. The introduction of Instant Controlled Pressure Drop (DIC) technology revolutionized nut candying by enhancing flavor penetration and reducing processing time.

- Traditional Candying - Utilizes prolonged boiling or soaking in sugar syrup to achieve sweetness and preservation.

- Instant Controlled Pressure Drop (DIC) - Applies rapid pressure changes to improve sugar infusion and texture in nuts.

- Historical Shift - Transitioned from labor-intensive techniques to efficient, technology-driven methods that maintain nutritional value.

Advancements in DIC technology mark a significant milestone in the historical evolution of nut candying methods by optimizing both quality and production efficiency.

Key Differences Between Conventional and ICPD Candying Techniques

Conventional candying of nuts involves slow infusion of sugar syrup through prolonged boiling, which can lead to uneven coating and longer processing times. This traditional method often results in a stickier texture and less uniform sweetness distribution across the nuts.

Instant Controlled Pressure Drop (ICPD) candying uses rapid pressure changes to enhance syrup penetration and drying efficiency, producing a crisper texture and more consistent sugar coating. ICPD technology significantly reduces processing time while improving flavor retention and product shelf life compared to conventional candying techniques.

Impact on Nut Texture and Crunchiness

Candying nuts through traditional methods often results in a softer texture due to prolonged exposure to heat and syrup, which can diminish their natural crunchiness. This conventional approach may lead to a slightly chewy coating, impacting the overall crispness of the nuts.

Instant Controlled Pressure Drop (DIC) candying preserves the nut's inherent crunch by rapidly reducing pressure, which enhances moisture evaporation and creates a crisp outer layer. The DIC technique maintains the nut's structure, delivering a more robust crunch and improved texture compared to traditional candying.

Flavor Retention in Traditional vs ICPD Candying

Flavor retention significantly differs between traditional candying and Instant Controlled Pressure Drop (ICPD) candying methods for nuts. ICPD candying preserves more natural nut aromas and flavors by minimizing heat exposure compared to traditional prolonged candying processes.

- Traditional Candying Flavor Loss - Extended heat application during traditional candying causes volatilization and degradation of delicate nut flavors.

- ICPD Flavor Preservation - Rapid pressure drops in ICPD reduce thermal stress, maintaining higher levels of essential oils and flavor compounds.

- Consumer Sensory Impact - Nuts candied via ICPD exhibit richer and fresher taste profiles, enhancing overall flavor intensity and acceptance.

Efficiency and Processing Time Comparison

Candying nuts using Instant Controlled Pressure Drop (DIC) significantly reduces processing time while enhancing efficiency compared to traditional candying methods. The DIC technique improves sugar infusion uniformity, resulting in a higher quality product with less energy consumption.

- Processing Time Reduction - DIC candying decreases processing duration by up to 70% compared to conventional candying.

- Energy Efficiency - Instant Controlled Pressure Drop uses lower thermal energy, reducing overall energy costs during candying.

- Sugar Infusion Quality - DIC promotes deeper and more uniform sugar penetration, enhancing nut flavor and texture.

Nutritional Outcomes: Preserving Vitamins and Nutrients

Candying nuts using traditional methods often results in significant vitamin loss and nutrient degradation due to prolonged exposure to high temperatures. Instant Controlled Pressure Drop (DIC) Candying preserves more vitamins, such as vitamin E and B-complex, by reducing processing time and minimizing thermal damage. This innovative technique enhances nutritional outcomes by maintaining antioxidant levels and improving the retention of essential minerals in candied nuts.

Commercial Applications and Scale-Up Potential

Candying nuts through traditional methods allows for consistent flavor infusion but presents challenges in uniformity and scalability for large commercial operations. Instant Controlled Pressure Drop (DIC) candying offers enhanced penetration and texture retention, making it more suitable for industrial-scale production.

DIC candying's rapid processing time and improved mass transfer significantly increase throughput, reducing energy consumption and operational costs compared to conventional candying. Its scalability supports large batch sizes with consistent quality, catering to high-demand commercial markets. The technology also enables customization of nut textures and flavors, providing a competitive edge in premium snack production.

Related Important Terms

Traditional Soak-Syrup Candying

Traditional soak-syrup candying involves immersing nuts in a sugar syrup for several hours to achieve gradual sugar absorption and a tender, evenly coated texture. Compared to Instant Controlled Pressure Drop (DIC) candying, which uses rapid pressure changes for faster drying and sugar crystallization, the soak-syrup method ensures deeper flavor infusion and a more uniform sweetness throughout the nut.

Icpc (Instant Controlled Pressure Drop) Candying

Instant Controlled Pressure Drop (ICPC) candying enhances nut preservation by rapidly infusing sugar syrup through sudden pressure changes, resulting in superior flavor penetration and texture retention compared to traditional candying methods. This technique reduces processing time while maintaining nut integrity, improving shelf life and sensory qualities.

Pulsed Vacuum Candying

Pulsed Vacuum Candying enhances nut preservation by alternating vacuum pressures to improve syrup penetration, resulting in superior flavor infusion and texture compared to traditional candying methods. This technique outperforms Instant Controlled Pressure Drop Candying by enabling precise control over infusion cycles, reducing processing time while maintaining nut integrity and sweetness uniformity.

DIC (Détente Instantanée Contrôlée) Technology

DIC (Detente Instantanee Controlee) technology enhances candying by rapidly applying and releasing pressure, which improves sugar infusion and maintains the structural integrity of nuts compared to traditional candying methods. This instant controlled pressure drop process ensures uniform texture, reduces processing time, and preserves the nutritional quality of candied nuts.

Osmotic Dehydration Enhancement

Candying nuts through traditional osmotic dehydration involves prolonged immersion in sugar solutions, resulting in gradual moisture loss and sugar infusion. Instant Controlled Pressure Drop (DIC) candying significantly enhances osmotic dehydration efficiency by creating micro-porous structures within nut tissues, accelerating mass transfer and reducing processing time while preserving texture and flavor.

Textural Aeration Candying

Textural aeration in candying transforms nuts by creating a light, crisp exterior through traditional slow sugar infusion, enhancing crunch and flavor retention. Instant Controlled Pressure Drop candying accelerates this process by rapidly infusing sugar syrup under controlled pressure changes, resulting in uniformly aerated, tender nuts with superior crispness and reduced processing time.

Rapid Infusion Candying

Rapid infusion candying enhances the penetration of sugar syrup into nuts by using high-pressure cycles, significantly reducing processing time compared to traditional candying methods. Instant Controlled Pressure Drop (DIC) technology exploits rapid pressure variations to create a porous structure in nuts, facilitating superior syrup absorption and improving texture uniformity in the final product.

Nut Porosity Modulation

Candying enhances nut porosity by allowing gradual sugar infusion, increasing flavor retention and texture uniformity. Instant Controlled Pressure Drop Candying rapidly modulates nut porosity through pressure-induced microstructure expansion, resulting in superior sugar uptake and crispness.

Low-Temperature Pressure Candying

Low-temperature pressure candying preserves the natural texture and flavor of nuts by gently infusing sugar syrup at controlled temperatures, preventing heat damage often seen in conventional candying. Instant Controlled Pressure Drop (DIC) candying enhances diffusion rates and reduces processing time, but may alter the nut's microstructure compared to the more delicate low-temperature pressure technique.

Candying vs Instant Controlled Pressure Drop Candying for nuts. Infographic

cookingdiff.com

cookingdiff.com