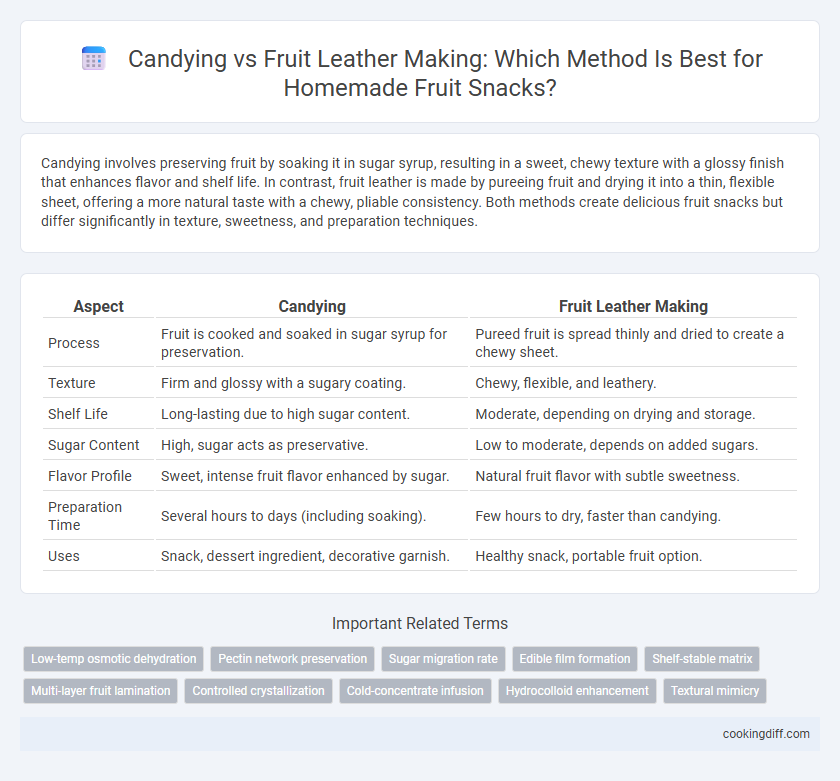

Candying involves preserving fruit by soaking it in sugar syrup, resulting in a sweet, chewy texture with a glossy finish that enhances flavor and shelf life. In contrast, fruit leather is made by pureeing fruit and drying it into a thin, flexible sheet, offering a more natural taste with a chewy, pliable consistency. Both methods create delicious fruit snacks but differ significantly in texture, sweetness, and preparation techniques.

Table of Comparison

| Aspect | Candying | Fruit Leather Making |

|---|---|---|

| Process | Fruit is cooked and soaked in sugar syrup for preservation. | Pureed fruit is spread thinly and dried to create a chewy sheet. |

| Texture | Firm and glossy with a sugary coating. | Chewy, flexible, and leathery. |

| Shelf Life | Long-lasting due to high sugar content. | Moderate, depending on drying and storage. |

| Sugar Content | High, sugar acts as preservative. | Low to moderate, depends on added sugars. |

| Flavor Profile | Sweet, intense fruit flavor enhanced by sugar. | Natural fruit flavor with subtle sweetness. |

| Preparation Time | Several hours to days (including soaking). | Few hours to dry, faster than candying. |

| Uses | Snack, dessert ingredient, decorative garnish. | Healthy snack, portable fruit option. |

Introduction to Candying and Fruit Leather Making

Candying is a preservation technique that involves soaking fruit in sugar syrup to create sweet, glazed fruit snacks with a long shelf life. Fruit leather making, on the other hand, involves pureeing fruit and drying it into thin, flexible sheets, retaining much of the fruit's natural flavor and nutrients. Both methods transform fruit into portable snacks but differ significantly in texture, process, and sugar content.

Historical Background of Candying and Fruit Leather

Candying dates back to ancient civilizations such as Egypt and India, where sugar preservation techniques were developed to extend the shelf life of fruits. This method involves soaking fruit in sugar syrup, which crystallizes to create a sweet, chewy texture that was prized in medieval Europe and Asia.

Fruit leather making has roots in indigenous cultures worldwide, especially in Native American and Middle Eastern traditions, where pureed fruit is spread thin and dried to produce a nutritious, portable snack. This drying technique preserves fruit flavor and nutrients without added sugars, contrasting with candying's sugar-intensive process.

Ingredients Used in Candying vs Fruit Leather

Candying involves preserving fruit by soaking it in sugar syrup, primarily using whole or large pieces of fruit along with granulated sugar and sometimes corn syrup. The high sugar concentration in candying acts as a preservative, enhancing the fruit's sweetness and texture.

Fruit leather making uses pureed fruit mixed with minimal or no additional sweeteners, often incorporating natural pectin and occasionally lemon juice to aid in setting and flavor balance. This method emphasizes the natural taste and nutrients of the fruit, creating a chewy, dried snack without the heavy sugar content found in candying.

Step-by-Step Candying Process

Candying fruit involves preserving fruit by slowly cooking it in sugar syrup, which infuses sweetness and extends shelf life. Fruit leather making, in contrast, purees the fruit and dehydrates it into a thin, chewy snack without added sugars.

- Preparation - Fruits are peeled, sliced, and cleaned before candying to ensure even syrup absorption.

- Syrup Cooking - Fruit pieces are simmered gently in progressively concentrated sugar syrup to replace water content with sugar.

- Drying and Coating - After cooking, candied fruit is dried and often coated with powdered sugar to prevent stickiness and preserve texture.

Fruit Leather Making Techniques

Fruit leather making involves pureeing fruit and spreading it thinly before drying, preserving the natural flavors and nutrients without added sugars. This technique contrasts with candying, which relies on soaking fruit in sugar syrup to create a sweetened, chewy texture.

To create fruit leather, blend ripe fruit with a small amount of lemon juice to enhance flavor and prevent browning. Spread the mixture evenly on a lined dehydrator tray or baking sheet, then dry at low temperatures until pliable but not sticky. Proper drying ensures a long-lasting, convenient fruit snack with a concentrated, tangy taste.

Texture and Flavor Differences

How do the textures and flavors differ between candying and fruit leather making for fruit snacks? Candying preserves the fruit's shape and creates a firm, crystallized texture with intensified sweetness due to sugar infusion. Fruit leather making results in a pliable, chewy texture with concentrated natural fruit flavors and tangy notes from slow drying.

Nutritional Comparison: Candying vs Fruit Leather

Candying fruit significantly increases sugar content, resulting in higher calories but longer shelf life, whereas fruit leather retains more fiber with moderate sugar levels. Both processes preserve fruit fructose, but fruit leather offers better nutrient density and lower added sugars.

- Caloric Impact - Candying raises calories due to added sugars, while fruit leather maintains lower calorie density by using natural fruit sugars.

- Fiber Content - Fruit leather preserves dietary fiber essential for digestion; candying removes most fiber through peeling and soaking.

- Vitamin Retention - Fruit leather retains more vitamins like vitamin C, whereas candying exposes fruit to heat and syrup, leading to nutrient degradation.

Choosing fruit leather enhances nutritional value and reduces excessive sugar intake compared to candied fruit snacks.

Shelf Life and Storage Considerations

| Candying extends shelf life by coating fruit in sugar, which acts as a preservative and inhibits microbial growth, allowing storage at room temperature for several months without refrigeration. |

| Fruit leather has a shorter shelf life, usually lasting 1 to 2 months when stored in airtight containers and kept in a cool, dry place, as it retains higher moisture content that encourages spoilage. |

| Proper storage for candying involves sealed containers away from humidity, while fruit leather requires airtight packaging and refrigeration to maximize freshness and prevent mold development. |

Popular Fruits for Candying and Fruit Leather

Popular fruits for candying include cherries, pineapple, and ginger due to their firm texture and vibrant flavors that hold well during the candying process. For fruit leather, apples, berries, and mangoes are preferred because their natural pectin content and juice create a smooth, pliable consistency when dried. Both methods highlight the unique qualities of these fruits, offering distinct textures and taste profiles in fruit snacks.

Related Important Terms

Low-temp osmotic dehydration

Low-temp osmotic dehydration preserves fruit texture and nutrients during candying, resulting in a chewier, more naturally flavored snack compared to fruit leather making, which often blends and dries fruit into a uniform, pliable sheet. Candying maintains individual fruit pieces through slow sugar infusion at lower temperatures, enhancing shelf life and sweetness without the gummy consistency typical of fruit leathers.

Pectin network preservation

Candying preserves the fruit's pectin network by slowly infusing sugar, which maintains the fruit's natural structure and chewiness. In contrast, fruit leather making breaks down the pectin through pureeing and drying, resulting in a homogenized, flexible texture rather than preserving the cellular integrity.

Sugar migration rate

Candying preserves fruit by slowly replacing water with sugar through osmotic dehydration, resulting in a lower sugar migration rate that maintains fruit texture and flavor integrity. In contrast, fruit leather making blends fruit puree with sugar, leading to a higher sugar migration rate and a uniform, chewy texture due to dehydration and sugar concentration throughout.

Edible film formation

Candying involves infusing fruit with sugar syrup, creating a thick, crystalline coating that acts as an edible preservative film, enhancing flavor and texture. In contrast, fruit leather making produces a continuous, pliable edible film through dehydration of pureed fruit, concentrating natural sugars and fibers into a chewy, shelf-stable snack.

Shelf-stable matrix

Candying fruit involves preserving whole fruit in sugar syrup, creating a shelf-stable matrix with low water activity that inhibits microbial growth, whereas fruit leather making concentrates pureed fruit into a dehydrated, flexible sheet with reduced moisture content and a longer shelf life. Candying maintains the fruit's shape and texture while fruit leather offers a compact, lightweight snack form, both leveraging sugar and dehydration to enhance stability.

Multi-layer fruit lamination

Candying preserves fruit by infusing sugar syrup, enhancing shelf life and sweetness, while multi-layer fruit lamination in fruit leather making involves layering pureed fruit to create complex textures and flavors in snack bars. This multi-layer technique allows for tailored taste profiles and improved structural integrity compared to the single-layer candying process.

Controlled crystallization

Controlled crystallization in candying preserves fruit texture and enhances sweetness through precise sugar infusion, resulting in a glossy, firm product. Fruit leather making involves pureeing and dehydrating fruit without crystallization, producing a chewy, flexible snack with concentrated fruit flavor but lacking the structured sugar matrix found in candied fruits.

Cold-concentrate infusion

Cold-concentrate infusion in candying preserves fruit texture and intensifies natural sweetness by slowly replacing water with sugar, differing from fruit leather making, which involves pureeing and dehydrating fruits into a flexible, chewy sheet. This method retains cellular structure and delivers a distinct, vibrant flavor profile compared to the homogenous taste and texture characteristic of fruit leather snacks.

Hydrocolloid enhancement

Candying preserves fruit through sugar infusion, yielding a glossy, firm texture enhanced by hydrocolloids like pectin and gelatin for improved moisture retention and chewiness. In contrast, fruit leather making relies on hydrocolloid thickening agents such as xanthan gum or guar gum to create a flexible, pliable snack with controlled water activity and enhanced shelf stability.

Candying vs Fruit leather making for fruit snacks. Infographic

cookingdiff.com

cookingdiff.com