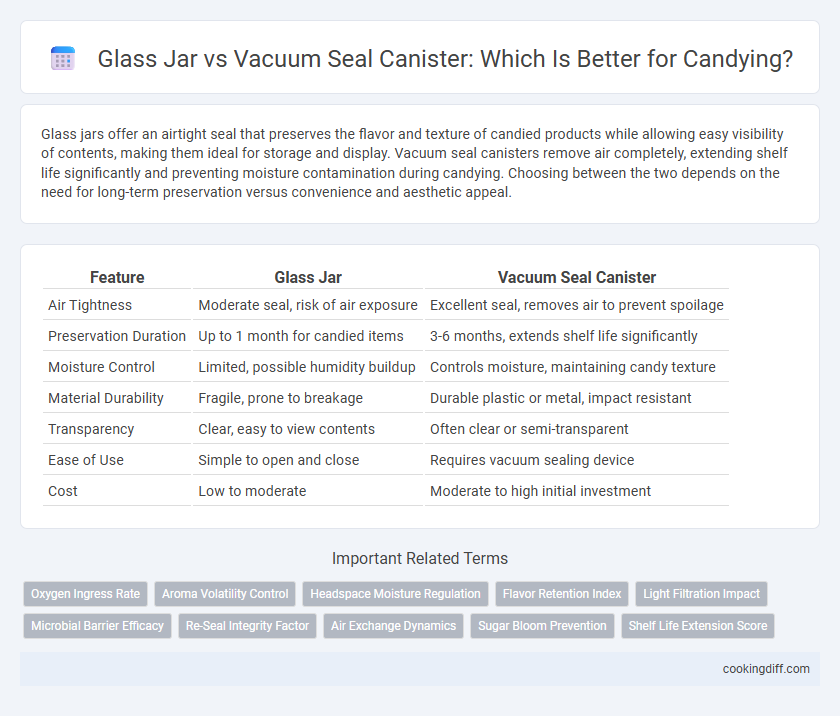

Glass jars offer an airtight seal that preserves the flavor and texture of candied products while allowing easy visibility of contents, making them ideal for storage and display. Vacuum seal canisters remove air completely, extending shelf life significantly and preventing moisture contamination during candying. Choosing between the two depends on the need for long-term preservation versus convenience and aesthetic appeal.

Table of Comparison

| Feature | Glass Jar | Vacuum Seal Canister |

|---|---|---|

| Air Tightness | Moderate seal, risk of air exposure | Excellent seal, removes air to prevent spoilage |

| Preservation Duration | Up to 1 month for candied items | 3-6 months, extends shelf life significantly |

| Moisture Control | Limited, possible humidity buildup | Controls moisture, maintaining candy texture |

| Material Durability | Fragile, prone to breakage | Durable plastic or metal, impact resistant |

| Transparency | Clear, easy to view contents | Often clear or semi-transparent |

| Ease of Use | Simple to open and close | Requires vacuum sealing device |

| Cost | Low to moderate | Moderate to high initial investment |

Introduction: Importance of Proper Storage in Candying

Proper storage is crucial in candying to maintain flavor, texture, and shelf life. Choosing the right container helps prevent moisture and air exposure that can spoil candies.

Glass jars offer airtight seals and visibility, ideal for small batches and delicate candies. Vacuum seal canisters provide superior air removal, extending freshness for longer-term storage.

Overview: Glass Jars and Vacuum Seal Canisters Defined

Glass jars are transparent containers made from tempered glass, commonly used for storing candied fruits and sweets due to their airtight sealing capabilities and visual appeal. Vacuum seal canisters are durable, airtight containers designed to remove air, significantly extending the shelf life of candy by preventing oxidation and moisture intrusion.

The choice between glass jars and vacuum seal canisters depends on factors like storage duration and preservation needs in candying processes. Glass jars allow easy monitoring of candy without opening, while vacuum seal canisters provide superior protection against spoilage and staleness during long-term storage.

Preserving Freshness: Which Method Prevails?

Vacuum seal canisters excel at preserving the freshness of candied fruits by eliminating air, which significantly slows oxidation and mold growth. Glass jars, while airtight when properly sealed, may allow minimal air exchange over time, potentially reducing shelf life. For long-term candying preservation, vacuum seal canisters provide a more effective barrier against moisture and contaminants.

Moisture Control: Impact on Sugared Delicacies

Glass jars provide a tight seal that moderately controls moisture, helping maintain the crisp texture of sugared delicacies during candying. Vacuum seal canisters excel at moisture control by removing air, significantly extending shelf life and preserving sweetness and texture.

Compared to glass jars, vacuum seal canisters create an anaerobic environment that minimizes sugar crystallization and prevents sticky clumping. This advanced moisture control protects delicate candy coatings from humidity fluctuations, ensuring optimal flavor retention. Choosing the appropriate container is essential for maintaining the quality and appearance of candied treats.

Air-Tightness: Comparing Seal Efficacy

Glass jars offer reliable air-tight seals with rubber gaskets and metal clamps that prevent moisture and air from entering, preserving the candy's texture and flavor. Vacuum seal canisters remove air before sealing, creating a stronger barrier against oxidation and extending candy shelf life significantly. Both options ensure effective protection, but vacuum seal canisters typically provide a superior seal, ideal for long-term candy storage.

Visibility and Monitoring: Transparency Benefits

| Glass jars provide superior visibility during the candying process, allowing for easy monitoring of sugar crystallization and fruit texture without opening the container. Transparent glass eliminates guesswork, enabling precise observation of color changes and syrup consistency. Vacuum seal canisters often utilize opaque materials, limiting visual inspection and requiring frequent opening that can disrupt the candying environment. |

Reactivity and Safety: Material Considerations

Glass jars are non-reactive and safe for candying acidic ingredients, ensuring flavors remain pure and uncontaminated. Vacuum seal canisters often use metal components that may react with acidic or sugary substances, potentially altering taste or safety.

- Glass jars are chemically inert - preventing unwanted reactions with candying ingredients and preserving flavor integrity.

- Vacuum seal canisters may contain reactive metals - which can leach into candy when exposed to acidic or sugary mixtures.

- Glass jars offer safer long-term storage - reducing risks of contamination or chemical interaction during candying processes.

Ease of Use and Cleaning for Candying Purposes

Glass jars offer straightforward cleaning with wide mouths that make scooping and rinsing residue easier, while vacuum seal canisters often have intricate sealing mechanisms requiring more careful maintenance. For candying purposes, glass jars simplify the process by allowing easy visibility and access to contents, whereas vacuum seal canisters provide better airtight storage but add complexity to cleaning.

- Glass jars feature wide openings - facilitating effortless scooping and cleaning of sticky candy remnants.

- Vacuum seal canisters have complex seals - necessitating thorough disassembly and drying to maintain hygiene.

- Glass jars allow clear visibility - aiding in monitoring candy stages without opening the container.

Cost and Availability: Budget-Friendly Options

Which is more cost-effective for candying: glass jars or vacuum seal canisters? Glass jars are typically more budget-friendly and widely available at most retail stores, making them accessible for hobbyists and small-scale candying projects. Vacuum seal canisters often come at a higher initial cost and may require specific equipment, limiting their availability and increasing overall expenses.

Related Important Terms

Oxygen Ingress Rate

Glass jars exhibit a low oxygen ingress rate due to their airtight seals and non-porous surfaces, making them highly effective for preserving candied fruits by minimizing oxidation. Vacuum seal canisters further reduce oxygen exposure by actively removing air, resulting in superior freshness retention and extended shelf life for candying applications.

Aroma Volatility Control

Vacuum seal canisters significantly reduce aroma volatility in candying by creating an airtight environment that preserves the natural fragrance and flavors, preventing the escape of volatile compounds. Glass jars, while airtight, may allow slight aroma loss over time due to less effective sealing, making vacuum seal canisters superior for long-term aroma preservation in candying processes.

Headspace Moisture Regulation

Glass jars provide a tighter seal but can trap excess moisture, potentially affecting candy texture during storage. Vacuum seal canisters excel in regulating headspace moisture by removing air and moisture, preserving candy freshness and preventing crystallization.

Flavor Retention Index

Vacuum seal canisters score higher on the Flavor Retention Index compared to glass jars, maintaining candy freshness and aroma for up to 30% longer by preventing oxygen exposure. Glass jars, while visually appealing and airtight, allow minimal air exchange, leading to a 15-20% faster decline in flavor intensity over the same period.

Light Filtration Impact

Glass jars provide moderate light filtration, protecting candied items from excessive exposure that can degrade color and flavor. Vacuum seal canisters offer superior light protection through opaque or tinted materials, preserving the candy's freshness and preventing oxidation more effectively.

Microbial Barrier Efficacy

Glass jars provide a robust microbial barrier due to their airtight sealing and impermeable surface, effectively preventing contamination during candying processes, while vacuum seal canisters enhance this protection by removing air and reducing oxidation, further inhibiting microbial growth. The combination of low oxygen exposure and hermetic sealing in vacuum seal canisters typically results in superior preservation of candied products compared to standard glass jars.

Re-Seal Integrity Factor

Glass jars offer superior re-seal integrity due to their durable, airtight lids that prevent moisture and air from compromising candied treats, ensuring prolonged freshness. Vacuum seal canisters also provide strong airtight seals but may lose effectiveness over repeated use, making glass jars a more reliable choice for maintaining candy quality over time.

Air Exchange Dynamics

Glass jars offer limited air exchange due to their rigid, airtight lids, effectively preserving candy by minimizing oxidation and moisture buildup, while vacuum seal canisters actively remove air to create a near-zero oxygen environment, significantly extending shelf life by inhibiting microbial growth and staleness. The superior air exchange control in vacuum seal canisters optimizes candy texture and flavor retention compared to glass jars, which rely solely on passive sealing.

Sugar Bloom Prevention

Vacuum seal canisters minimize air exposure, significantly reducing sugar bloom in candied fruits by maintaining consistent humidity and temperature control. Glass jars, while airtight, may not provide the same level of moisture regulation, increasing the risk of crystalline sugar formation on the surface.

Glass Jar vs Vacuum Seal Canister for candying. Infographic

cookingdiff.com

cookingdiff.com