Using a traditional thermometer provides direct contact measurement and typically offers more consistent accuracy for monitoring candying temperatures. Infrared thermometers deliver rapid, non-contact readings but may be less reliable due to surface reflections and uneven heating in sugar mixtures. Selecting the appropriate tool enhances precision in achieving the desired candy stage for perfect results.

Table of Comparison

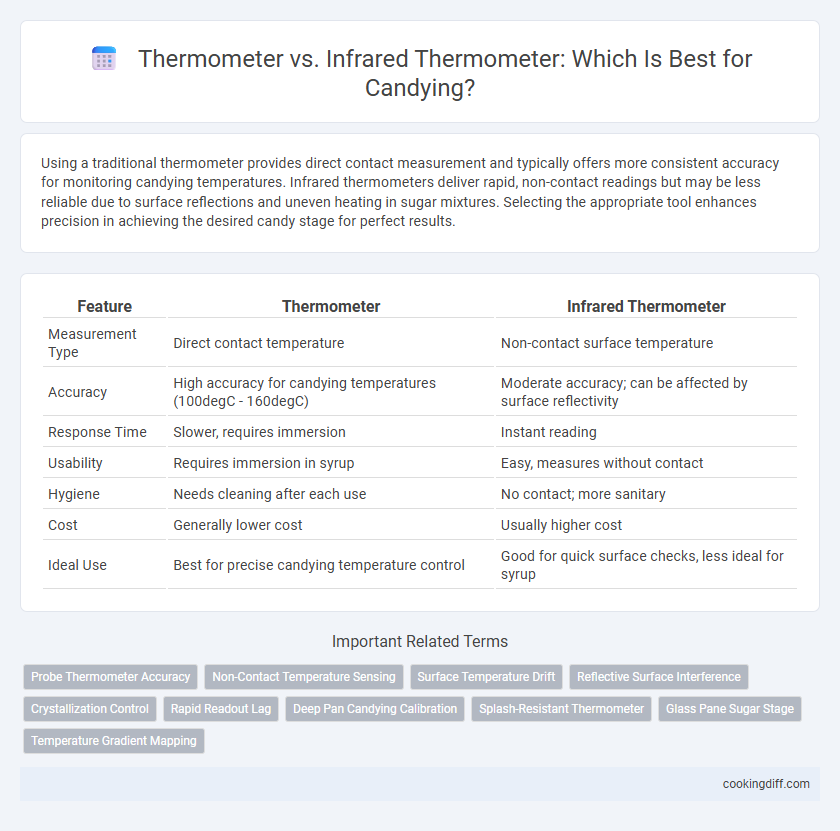

| Feature | Thermometer | Infrared Thermometer |

|---|---|---|

| Measurement Type | Direct contact temperature | Non-contact surface temperature |

| Accuracy | High accuracy for candying temperatures (100degC - 160degC) | Moderate accuracy; can be affected by surface reflectivity |

| Response Time | Slower, requires immersion | Instant reading |

| Usability | Requires immersion in syrup | Easy, measures without contact |

| Hygiene | Needs cleaning after each use | No contact; more sanitary |

| Cost | Generally lower cost | Usually higher cost |

| Ideal Use | Best for precise candying temperature control | Good for quick surface checks, less ideal for syrup |

Introduction to Candying and Temperature Control

Temperature control is crucial in candying to achieve the perfect texture and consistency. Choosing between a traditional thermometer and an infrared thermometer impacts the accuracy and method of temperature measurement during the cooking process.

- Traditional Thermometer - Measures the actual temperature of the candy mixture by direct contact, providing precise readings essential for sugar stages like soft ball and hard crack.

- Infrared Thermometer - Offers a non-contact way to measure surface temperature quickly, but may be less accurate for thick or boiling mixtures due to surface reflections and steam.

- Importance of Accurate Measurement - Precise temperature readings prevent crystallization, ensuring smooth and consistent candy texture throughout the cooking process.

Why Accurate Temperature Matters in Candy Making

Accurate temperature measurement is critical in candying to achieve the desired texture and prevent crystallization. Traditional thermometers provide direct contact readings, while infrared thermometers offer non-contact temperature checks that may vary in precision.

- Consistency - Precise temperature ensures consistent candy texture and prevents burnt or undercooked batches.

- Precision - Traditional thermometers measure the candy mixture directly, giving reliable temperature data.

- Speed - Infrared thermometers deliver instant readings but can be affected by steam or surface reflections.

Choosing the right thermometer enhances control over the candying process and the final product quality.

Traditional Candy Thermometers: Features and Functions

Traditional candy thermometers typically feature a metal probe and a glass or stainless steel body, designed to clip onto pots for continuous temperature monitoring during candying. They measure temperature through direct contact, providing precise readings crucial for stages like soft ball or hard crack.

These thermometers often include calibration options, temperature ranges up to 400degF or higher, and clear, easy-to-read dials or digital displays. Unlike infrared thermometers, they detect the actual temperature of the sugar mixture rather than surface heat, ensuring accurate control in candy-making. Their durability and reliability make them a preferred choice among professional and home candy makers focused on consistent results.

Infrared Thermometers: Technology and Usability

Infrared thermometers utilize infrared technology to measure surface temperatures without direct contact, providing quick and accurate readings essential for precise candying processes. Their non-invasive design reduces contamination risk and allows continuous monitoring of sugar temperatures, crucial for achieving desired candy textures. These devices often feature digital displays and laser targeting for enhanced usability, making them ideal tools in both professional and home candy making.

Precision and Accuracy: Comparing Both Thermometers

Traditional candy thermometers provide precise temperature readings by direct contact with the sugar mixture, ensuring accurate monitoring crucial for achieving perfect candy texture. Infrared thermometers offer quick surface temperature measurements but may lack the accuracy needed for consistent candying results due to surface reflection and uneven heat distribution.

For candying, accuracy in temperature measurement directly impacts the final product's consistency and quality, making traditional thermometers more reliable for this purpose. Infrared thermometers are better suited for rapid checks but should be supplemented with contact thermometers for exact temperature control during candy making.

Ease of Use in a Candying Environment

Which thermometer offers greater ease of use in a candying environment? Traditional thermometers require direct contact with the hot sugar mixture, increasing the risk of burns and contamination. Infrared thermometers provide quick, contactless temperature readings, enhancing safety and efficiency during candying.

Safety Considerations for High-Heat Sugar Work

| Safety Considerations | Traditional Thermometer | Infrared Thermometer |

|---|---|---|

| Contact with Hot Sugar | Requires direct immersion in boiling sugar, posing burn risks. | Measures temperature from a distance, eliminating burn hazards. |

| Accuracy in High Heat | Accurate temperature readings essential for precise sugar stages. | May have difficulty measuring reflective or steam-covered surfaces accurately. |

| Ease of Use | Requires careful handling to avoid splashes and burns during insertion. | Allows quick, non-contact readings, enhancing overall safety during candying. |

Cleaning and Maintenance Requirements

Traditional candy thermometers require thorough cleaning after each use to remove sticky sugar residues, which can be time-consuming and may affect accuracy if not properly maintained. Regular calibration is also necessary to ensure precise temperature readings during candying processes.

Infrared thermometers offer a more hygienic alternative with minimal cleaning required since they measure temperature from a distance without direct contact with hot syrup or sugar. Maintenance mainly involves keeping the sensor lens clean and ensuring batteries are replaced for consistent performance.

Cost and Accessibility for Home and Professional Cooks

Traditional candy thermometers are generally more affordable and widely accessible for both home and professional cooks, while infrared thermometers tend to be pricier but offer quick, contactless temperature readings. The choice depends on budget constraints and the need for precise temperature control in candying processes.

- Cost-effectiveness - Candy thermometers provide a budget-friendly option suitable for frequent use in home kitchens.

- Accessibility - Infrared thermometers may be less accessible due to higher initial investment and less common usage in candying.

- Practicality - Professionals may prefer infrared thermometers for speed, but traditional thermometers remain reliable and easy to use.

Related Important Terms

Probe Thermometer Accuracy

Probe thermometers provide superior accuracy for candying by measuring the internal temperature of sugar solutions directly, ensuring precise control over critical stages like soft ball or hard crack. Infrared thermometers, while convenient for surface readings, often deliver inconsistent results due to reflective properties and cannot reliably gauge the solution's true internal temperature needed for perfect candy texture.

Non-Contact Temperature Sensing

Infrared thermometers enable precise, non-contact temperature sensing essential for candying, reducing contamination risk and allowing quick surface temperature readings without immersion. Traditional thermometers require direct contact with the candy mixture, which can introduce impurities and slow the process due to the need for stabilization time.

Surface Temperature Drift

Infrared thermometers offer non-contact measurement but often suffer from surface temperature drift due to emissivity variations and reflective interference, leading to less accurate readings during candying processes. Traditional probe thermometers provide direct, stable readings by measuring internal temperature, minimizing errors caused by surface inconsistencies or ambient conditions.

Reflective Surface Interference

Traditional thermometers can provide accurate candying temperature measurements but may be affected by direct contact heat transfer limitations, while infrared thermometers face challenges with reflective surfaces of molten sugar, which can distort temperature readings due to infrared reflection. Using a thermometer with a probe tip designed for high-temperature contact or applying a non-reflective coating to the candy surface helps minimize reflective surface interference and ensures precise temperature control during candying.

Crystallization Control

Traditional candy thermometers provide direct contact temperature readings essential for precise sugar crystallization control, ensuring consistent texture and preventing graininess. Infrared thermometers offer non-contact surface temperature measurements but may lack accuracy in detecting internal candy temperatures, risking inconsistent crystallization.

Rapid Readout Lag

Infrared thermometers offer rapid readout with minimal lag, providing instant surface temperature measurements essential for precise candying stages like caramelization and sugar crystallization. Traditional thermometers display temperature changes more slowly, which can delay adjustments and affect the candy's texture and consistency.

Deep Pan Candying Calibration

Deep pan candying requires precise temperature control, where a traditional thermometer offers direct contact measurement for thorough calibration, ensuring consistent sugar crystallization. Infrared thermometers provide rapid surface readings but may lack depth accuracy, making them less reliable for deep pan candy calibration.

Splash-Resistant Thermometer

Splash-resistant thermometers offer precise temperature control essential for candying, ensuring accurate readings during boiling sugar stages without damage from splashes. Infrared thermometers provide quick surface temperature checks but lack the reliability of splash-resistant models in measuring the internal temperature critical for achieving perfect candy consistency.

Glass Pane Sugar Stage

A traditional candy thermometer provides precise, direct measurements essential for monitoring the Glass Pane sugar stage at 280degF (138degC), ensuring accurate sugar-crystal transformation during candying. Infrared thermometers, while offering quick surface temperature readings, may deliver inconsistent results at this critical stage due to sugar's reflective and translucent properties.

Thermometer vs Infrared Thermometer for candying. Infographic

cookingdiff.com

cookingdiff.com