Using a traditional thermometer for candying provides precise, direct temperature readings by immersion, crucial for achieving the exact sugar stages needed in candy making. Infrared sensors offer a non-contact method, allowing faster measurements and reducing contamination risks, but they may be less accurate due to surface temperature variations. Choosing between the two depends on the balance between accuracy and convenience required during the candying process.

Table of Comparison

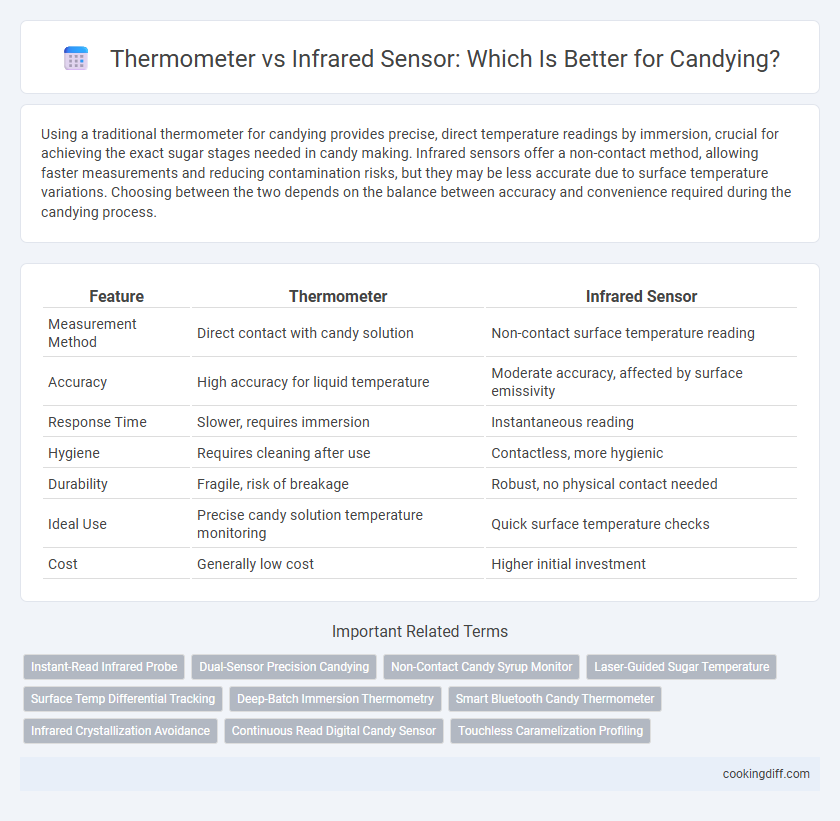

| Feature | Thermometer | Infrared Sensor |

|---|---|---|

| Measurement Method | Direct contact with candy solution | Non-contact surface temperature reading |

| Accuracy | High accuracy for liquid temperature | Moderate accuracy, affected by surface emissivity |

| Response Time | Slower, requires immersion | Instantaneous reading |

| Hygiene | Requires cleaning after use | Contactless, more hygienic |

| Durability | Fragile, risk of breakage | Robust, no physical contact needed |

| Ideal Use | Precise candy solution temperature monitoring | Quick surface temperature checks |

| Cost | Generally low cost | Higher initial investment |

Introduction to Candying: Precision Matters

Candying requires precise temperature control to ensure the sugar mixture reaches the exact stage for optimal texture and flavor. Traditional thermometers, such as candy or digital probe thermometers, provide direct contact measurements, offering reliable accuracy during cooking.

Infrared sensors measure surface temperature without contact, enabling quick readings but may be less accurate for thick or boiling mixtures. Selecting the right temperature tool directly impacts candy quality, making precision essential in the candying process.

Traditional Candy Thermometers: Features and Functionality

Traditional candy thermometers offer direct temperature readings by immersing the probe into the sugar mixture, ensuring accurate monitoring during the candying process. Infrared sensors provide non-contact temperature measurements but may lack precision when detecting the temperature of viscous or opaque substances.

- Direct Contact Measurement - Traditional candy thermometers measure temperature by direct immersion, providing precise readings critical for sugar stages.

- Wide Temperature Range - They typically cover a temperature range from 100degF to 400degF, suitable for various candying requirements.

- Simple Calibration and Use - These thermometers are easy to calibrate and use, making them reliable tools for home and professional candy making.

Infrared Sensors: How They Work in the Kitchen

Infrared sensors measure surface temperature by detecting the infrared radiation emitted from candy without direct contact, ensuring precise control during candying. This non-invasive method helps maintain ideal temperatures to prevent burning or crystallization, enhancing candy texture and flavor. In kitchen environments, infrared thermometers provide quick, accurate readings, improving efficiency and consistency in candy preparation.

Accuracy Comparison: Thermometer vs Infrared Sensor

Thermometers provide direct temperature readings by contact, ensuring high accuracy essential for precise candying stages like the soft ball and hard crack. Their reliance on physical contact reduces interference from environmental factors, making them dependable for consistent syrup temperature measurement.

Infrared sensors measure surface temperature without contact, offering quick readings but are susceptible to reflection and emissivity errors that can compromise accuracy. While convenient for rapid checks, they may not capture internal candy temperature accurately, impacting consistency in candying results.

Temperature Range and Responsiveness

| Temperature Range | Thermometers typically measure temperatures from -50degC to 300degC, suitable for precise candying processes, while infrared sensors usually cover a broader range of -50degC to 500degC, allowing for versatile temperature detection. |

|---|---|

| Responsiveness | Infrared sensors provide rapid, non-contact temperature readings ideal for monitoring candying stages in real time, whereas thermometers may require direct contact and slower response times, potentially affecting process efficiency. |

Ease of Use: Hands-On vs No-Contact Measurement

Thermometers require direct contact with the candy mixture, offering precise temperature readings but demanding hands-on attention and frequent stirring. Infrared sensors provide no-contact measurement, allowing quick temperature checks without contaminating the confectionery.

Using a thermometer involves inserting it into the candy, which can slow down the process and requires careful handling to avoid burns. Infrared sensors measure surface temperature instantly, enhancing safety and speeding up workflow in a candying setup. However, infrared readings may be less accurate for thick or bubbling mixtures compared to traditional thermometers.

Safety Considerations During Candying

Using a traditional thermometer during candying ensures accurate temperature readings by direct contact, reducing the risk of incorrect measurements that could lead to overheating or burning sugar. Infrared sensors offer a safer, non-contact method to monitor temperature, minimizing the chance of burns and contamination. Prioritizing precise and safe temperature monitoring tools helps prevent kitchen accidents and ensures the candy achieves the desired texture and consistency.

Cost and Accessibility of Measuring Tools

Which measuring tool offers better cost efficiency and accessibility for candying, a thermometer or an infrared sensor? Traditional candy thermometers are generally more affordable and widely accessible, making them a preferred choice for home candy makers. Infrared sensors, while providing non-contact temperature readings, tend to be more expensive and less common in typical kitchen settings.

Maintenance and Durability: Longevity of Each Option

Thermometers generally require regular calibration and careful handling to maintain accuracy over time, whereas infrared sensors demand less frequent maintenance due to their non-contact nature. Infrared sensors offer superior durability as they are less prone to wear and damage compared to traditional thermometers used in candying processes.

- Thermometer Calibration - Frequent calibration is necessary to ensure precise temperature readings during candying.

- Infrared Sensor Maintenance - Minimal upkeep is needed as these sensors avoid direct contact with hot surfaces.

- Durability Comparison - Infrared sensors tend to have a longer lifespan, reducing replacement frequency and downtime.

Related Important Terms

Instant-Read Infrared Probe

Instant-read infrared probes provide rapid, non-contact temperature measurements essential for precise candying, ensuring sugar syrup reaches the exact temperature for optimal texture and flavor. Unlike traditional thermometers, infrared sensors minimize contamination risk and improve efficiency by delivering accurate readings in seconds without immersing in hot liquids.

Dual-Sensor Precision Candying

Dual-sensor precision candying combines the accurate core temperature measurement of a traditional thermometer with the rapid surface temperature readings of an infrared sensor, ensuring consistent candy texture and preventing crystallization. This integration optimizes thermal control during the cooking process, enhancing product quality and reducing batches lost to improper temperature management.

Non-Contact Candy Syrup Monitor

Infrared sensors provide a non-contact method for monitoring candy syrup temperature, ensuring consistent candying without contamination risks associated with traditional thermometers. These sensors offer real-time, accurate temperature readings, improving process control and product quality in candy manufacturing.

Laser-Guided Sugar Temperature

Laser-guided infrared sensors provide precise, non-contact temperature measurements crucial for candying, enabling accurate monitoring of sugar's boiling point without contamination risks. Compared to traditional thermometers, laser-guided infrared technology offers faster response times and enhanced safety by eliminating direct contact with hot, molten sugar.

Surface Temp Differential Tracking

Thermometers provide precise, continuous temperature readings by direct contact, essential for accurate surface temperature monitoring during candying, while infrared sensors offer non-contact measurement but may face challenges in detecting subtle surface temperature differentials due to emissivity variations. Surface temp differential tracking is more reliable with thermometers, as they capture exact heat changes critical for sugar crystallization and caramelization control.

Deep-Batch Immersion Thermometry

Deep-batch immersion thermometry offers precise temperature control essential for candying by measuring the internal temperature of the sugar solution directly, ensuring accurate caramelization and preventing crystallization. Infrared sensors, while non-contact and fast, often fall short in deep-batch applications due to surface-only readings that may not reflect the true temperature of the immersed candy mixture.

Smart Bluetooth Candy Thermometer

Smart Bluetooth candy thermometers offer precise temperature monitoring essential for perfect candying, providing real-time data via smartphone apps, unlike traditional infrared sensors that measure surface temperature only. Their advanced connectivity ensures accurate control of sugar stages, improving consistency and reducing errors in candy recipes.

Infrared Crystallization Avoidance

Infrared sensors provide precise surface temperature readings during candying, enabling better control over crystallization by detecting hot spots that traditional thermometers may miss. This real-time, non-contact measurement reduces the risk of sugar crystallization, ensuring a smoother, higher-quality candy texture.

Continuous Read Digital Candy Sensor

Continuous read digital candy sensors offer precise temperature monitoring essential for candying by providing real-time data without physical contact, unlike traditional thermometers that require immersion and risk contamination. Infrared sensors enhance accuracy and safety during the candying process by instantly measuring surface temperatures, ensuring consistent texture and preventing overheating.

Thermometer vs Infrared Sensor for Candying. Infographic

cookingdiff.com

cookingdiff.com