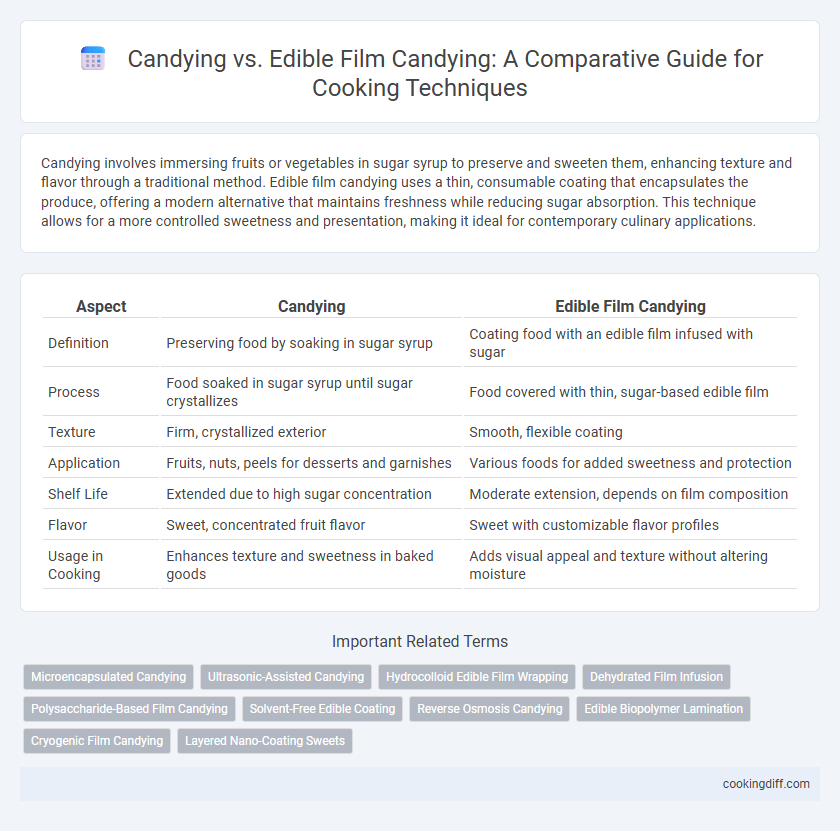

Candying involves immersing fruits or vegetables in sugar syrup to preserve and sweeten them, enhancing texture and flavor through a traditional method. Edible film candying uses a thin, consumable coating that encapsulates the produce, offering a modern alternative that maintains freshness while reducing sugar absorption. This technique allows for a more controlled sweetness and presentation, making it ideal for contemporary culinary applications.

Table of Comparison

| Aspect | Candying | Edible Film Candying |

|---|---|---|

| Definition | Preserving food by soaking in sugar syrup | Coating food with an edible film infused with sugar |

| Process | Food soaked in sugar syrup until sugar crystallizes | Food covered with thin, sugar-based edible film |

| Texture | Firm, crystallized exterior | Smooth, flexible coating |

| Application | Fruits, nuts, peels for desserts and garnishes | Various foods for added sweetness and protection |

| Shelf Life | Extended due to high sugar concentration | Moderate extension, depends on film composition |

| Flavor | Sweet, concentrated fruit flavor | Sweet with customizable flavor profiles |

| Usage in Cooking | Enhances texture and sweetness in baked goods | Adds visual appeal and texture without altering moisture |

Introduction to Candying and Edible Film Candying

Candying is a traditional cooking technique that preserves fruits or vegetables by immersing them in sugar syrup, enhancing flavor and extending shelf life. Edible film candying innovates this method by coating ingredients with a thin, consumable sugar-based film, creating a unique texture and presentation.

Traditional candying focuses on infusion of sweetness through prolonged soaking in concentrated sugar solutions, resulting in a dense, flavorful treat. Edible film candying employs edible polymer films combined with sugar to encase the ingredient, offering controlled sweetness release and improved visual appeal. Both methods emphasize sugar's preservative qualities while catering to different culinary preferences and applications.

Definitions: Traditional Candying vs Edible Film Candying

What distinguishes traditional candying from edible film candying in cooking? Traditional candying involves preserving fruits or vegetables by slowly cooking them in sugar syrup until fully saturated, resulting in a sweet, glossy treat. Edible film candying uses a thin, transparent edible coating infused with flavors or nutrients, creating a delicate candy layer without the lengthy syrup cooking process.

Historical Evolution of Candying Techniques

Candying dates back to ancient civilizations where fruits were preserved in honey or sugar to extend shelf life, while edible film candying emerged more recently through advancements in food technology allowing ultra-thin candy coatings. Both techniques have evolved to enhance texture and flavor retention in culinary applications.

- Ancient Candying Origins - Early candying methods used natural sweeteners like honey to preserve fruits and create early confectioneries.

- Introduction of Edible Films - Modern edible film candying utilizes biopolymers to form thin, transparent layers that protect food while adding sweetness.

- Technological Advancements - Innovations in food science have refined candying processes, focusing on preserving nutritional value and improving sensory qualities.

Key Ingredients in Each Method

Candying involves soaking fruit or vegetables in sugar syrup to preserve and sweeten them, relying primarily on sugar and water as its key ingredients. Edible film candying incorporates a thin, edible coating made from polysaccharides or proteins, enhancing texture and shelf life while also using sugar syrup.

- Sugar and water - Fundamental to candying, sugar acts as a preservative and sweetener dissolved in water to create the syrup.

- Polysaccharides or proteins - Used in edible film candying, these form the thin edible coating that encases the candy.

- Additional flavorings or acids - Sometimes included in both methods to adjust taste and improve preservation properties.

Process Comparison: Step-by-Step Guide

Candying involves soaking fruit or vegetables in a sugar syrup to preserve and enhance flavor, requiring multiple stages of boiling and drying. Edible film candying encapsulates the produce in a thin, flavored, edible coating that sets quickly and provides a different texture and protection.

The candying process follows a step-by-step method of blanching, simmering in syrup, and air-drying to achieve the desired sweetness and firmness. In contrast, edible film candying applies a liquid film evenly over the surface, where it solidifies without extended boiling or drying times.

Flavor and Texture Differences

Candying involves coating fruits or other ingredients with sugar syrup, resulting in a sweet, chewy texture and intensified natural flavors. This process enhances the ingredient's firmness while preserving its original taste profile.

Edible film candying uses a thin, transparent sugar-based layer that encapsulates the ingredient, offering a delicate crunch and a subtle sweet note without altering the core texture. The film acts as a flavor barrier, allowing the original taste to remain more distinct compared to traditional candying methods.

Nutritional Impact and Preservation

Candying preserves fruit by infusing it with sugar, which acts as a natural preservative but significantly increases the calorie and sugar content, affecting nutritional value. Edible film candying uses a thin, edible coating that protects the fruit while maintaining more of its original vitamins and minerals, resulting in a lower sugar impact. Both methods enhance shelf life, but edible film candying offers superior nutritional retention and reduced added sugars compared to traditional candying techniques.

Culinary Applications and Versatility

Candying preserves fruits or vegetables by soaking them in sugar syrup, creating a sweet, chewy texture ideal for baking, garnishing, and confectionery. Edible film candying involves encasing ingredients in a thin, transparent edible coating that enhances flavor while maintaining moisture and protecting freshness, offering innovative presentation options. Both techniques expand culinary versatility, with traditional candying favored for texture manipulation and edible film candying prized for decorative and preservation purposes.

Pros and Cons of Each Technique

Candying involves soaking fruit in sugar syrup to preserve and sweeten, while edible film candying encases the ingredient in a thin, consumable sugar-based layer. Each technique offers distinct culinary and preservation benefits that influence texture, flavor, and presentation.

- Traditional Candying preserves flavor depth - It allows the fruit's natural taste to intensify through prolonged sugar absorption.

- Edible film candying creates a protective barrier - This method prevents moisture loss and extends freshness without altering the core flavor significantly.

- Traditional candying can be time-consuming - The repeated boiling and soaking process requires several days for optimal results.

Choosing between candying and edible film candying depends on desired texture, shelf-life, and preparation time in culinary applications.

Related Important Terms

Microencapsulated Candying

Microencapsulated candying involves coating fruit or ingredients with a protective edible film that preserves texture and flavor while enhancing shelf life, in contrast to traditional candying which relies on sugar impregnation. This advanced edible film candying technique allows for better control over moisture and sugar content, resulting in improved cooking performance and a more refined taste experience.

Ultrasonic-Assisted Candying

Ultrasonic-assisted candying enhances the infusion of sugar syrup into fruits, resulting in a more uniform texture and accelerated processing time compared to traditional candying techniques. In contrast, edible film candying integrates sugar encapsulated within a biodegradable film, offering extended shelf life and improved structural integrity without compromising flavor absorption.

Hydrocolloid Edible Film Wrapping

Hydrocolloid edible film wrapping enhances candying by creating a thin, moisture-retentive barrier that preserves texture and flavor while preventing crystallization in fruits and confections. Unlike traditional candying, this technique uses hydrocolloid polymers to form edible films that improve shelf life and provide a controlled release of sweetness during cooking and consumption.

Dehydrated Film Infusion

Candying involves saturating fruits or vegetables with sugar to create a sweet, preserved treat, while edible film candying incorporates a dehydrated film infusion that enhances flavor absorption and texture retention. This method uses a thin, sugar-based film embedded with concentrated flavors, providing a controlled release of taste and a refined, chewable consistency in culinary applications.

Polysaccharide-Based Film Candying

Polysaccharide-based film candying utilizes natural polymers such as pectin, cellulose, and starch to create a thin, edible layer that enhances flavor and extends shelf life while maintaining texture in cooking. Unlike traditional candying, this technique offers improved moisture retention and controlled release of sweeteners, making it ideal for delicate fruits and confections.

Solvent-Free Edible Coating

Candying preserves fruit through sugar crystallization, creating a sweet, glossy exterior, whereas solvent-free edible film candying uses natural, water-based coatings to seal moisture and enhance texture without chemical solvents. This method maintains fruit integrity and adds protective barriers ideal for health-conscious cooking and allergen-friendly recipes.

Reverse Osmosis Candying

Reverse osmosis candying enhances fruit preservation by using a semipermeable membrane to extract water, concentrating natural sugars without heat, which retains texture and flavor better than traditional candying methods. Compared to edible film candying, this process reduces moisture content more uniformly, resulting in a product with improved shelf life and intensified sweetness while maintaining nutritional value.

Edible Biopolymer Lamination

Edible biopolymer lamination in candying enhances flavor infusion and texture preservation by forming a thin, breathable edible film around fruits or confections, enabling better moisture control compared to traditional candying methods. This technique improves shelf life and reduces sugar content while maintaining the natural appearance and nutritional value of the ingredients.

Cryogenic Film Candying

Cryogenic Film Candying enhances traditional candying by encapsulating ingredients in an ultra-thin, edible film using cryogenic temperatures, which locks in flavor and texture more effectively than conventional candying methods. This technique preserves the integrity of delicate foods while providing a crisp, transparent coating that improves shelf life and presentation in gourmet cooking.

Candying vs Edible Film Candying for cooking. Infographic

cookingdiff.com

cookingdiff.com