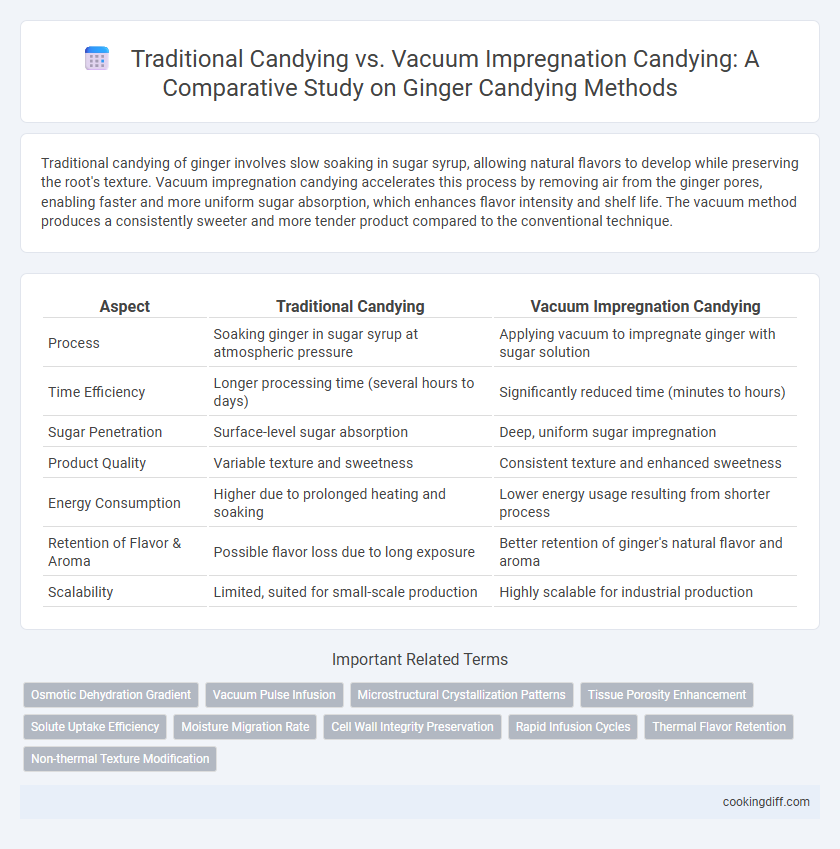

Traditional candying of ginger involves slow soaking in sugar syrup, allowing natural flavors to develop while preserving the root's texture. Vacuum impregnation candying accelerates this process by removing air from the ginger pores, enabling faster and more uniform sugar absorption, which enhances flavor intensity and shelf life. The vacuum method produces a consistently sweeter and more tender product compared to the conventional technique.

Table of Comparison

| Aspect | Traditional Candying | Vacuum Impregnation Candying |

|---|---|---|

| Process | Soaking ginger in sugar syrup at atmospheric pressure | Applying vacuum to impregnate ginger with sugar solution |

| Time Efficiency | Longer processing time (several hours to days) | Significantly reduced time (minutes to hours) |

| Sugar Penetration | Surface-level sugar absorption | Deep, uniform sugar impregnation |

| Product Quality | Variable texture and sweetness | Consistent texture and enhanced sweetness |

| Energy Consumption | Higher due to prolonged heating and soaking | Lower energy usage resulting from shorter process |

| Retention of Flavor & Aroma | Possible flavor loss due to long exposure | Better retention of ginger's natural flavor and aroma |

| Scalability | Limited, suited for small-scale production | Highly scalable for industrial production |

Introduction to Ginger Candying Methods

What distinguishes traditional candying from vacuum impregnation candying methods for ginger? Traditional candying involves soaking ginger slices in sugar syrup over extended periods, enabling gradual sugar absorption and flavor development. Vacuum impregnation accelerates this process by removing air from ginger tissues, allowing faster and more uniform sugar infusion while preserving the ginger's natural texture and aroma.

Overview of Traditional Candying Process

The traditional candying process for ginger involves slow boiling the ginger in sugar syrup until it achieves the desired sweetness and texture. This method relies on natural diffusion and evaporation to infuse sugar into the ginger fibers over several hours.

- Soaking - Fresh ginger is peeled and soaked in water to reduce bitterness before boiling.

- Boiling - Ginger is simmered in gradually concentrated sugar syrup to replace moisture with sugar.

- Drying - The candied ginger pieces are dried to form a crystalline sugar coating and enhance shelf life.

Understanding Vacuum Impregnation Candying

Vacuum impregnation candying for ginger enhances flavor penetration by creating a low-pressure environment that removes air from the ginger's porous structure, allowing syrup to infuse more deeply and uniformly. Traditional candying relies on osmotic diffusion, which is slower and results in less consistent sweetness and texture. This method significantly reduces processing time while maintaining the ginger's natural aroma and firmness.

Ingredient Preparation for Both Techniques

Ingredient preparation for traditional candying of ginger involves peeling, slicing, and soaking the ginger in sugar syrup for an extended period to achieve sweetness and texture. Vacuum impregnation candying uses reduced pressure to enhance syrup penetration, allowing for faster and more uniform sugar infusion in ginger slices.

- Peeling and slicing - Ginger is peeled and cut into uniform slices to ensure even cooking and syrup absorption.

- Soaking duration - Traditional candying requires prolonged soaking times, often several hours to days, for proper sugar infusion.

- Vacuum impregnation process - Reduced pressure conditions help remove air from ginger tissues, improving sugar syrup uptake within minutes.

Both methods begin with thorough cleaning and preparation of fresh ginger to maintain quality and flavor throughout the candying process.

Equipment Requirements: Traditional vs Vacuum

Traditional candying equipment for ginger involves simple tools such as large pots, boiling tanks, and drying racks, relying heavily on manual labor and prolonged heat application. In contrast, vacuum impregnation candying requires specialized vacuum chambers and pumps to efficiently infuse sugar syrups under controlled pressure conditions.

Vacuum impregnation systems optimize the infusion process, reducing processing time and improving product uniformity with automated controls. Traditional methods lack precision equipment, resulting in longer processing durations and variable syrup penetration quality.

Step-by-Step: Traditional Ginger Candying

Traditional ginger candying involves peeling fresh ginger, slicing it thinly, and boiling it in a sugar syrup until the slices become translucent and tender. This process typically requires multiple stages of soaking and simmering to ensure the ginger absorbs the sugar fully while maintaining its natural spiciness.

The ginger slices are then drained and dried on racks for several hours or days to develop a chewy texture and a crystallized sugar coating. This method, though time-consuming, enhances the ginger's flavor and preserves its fibrous structure without the need for specialized equipment.

Step-by-Step: Vacuum Impregnation for Ginger

Vacuum impregnation for ginger involves placing ginger slices in a vacuum chamber to remove air from the tissue pores, followed by immersion in a sugar syrup solution under vacuum. This process enhances sugar absorption, resulting in a more uniform and flavorful candying effect compared to traditional methods.

The steps begin by washing and slicing fresh ginger, then loading the slices into the vacuum chamber where air is extracted at pressures around 0.05-0.1 atm. Sugar syrup is introduced while maintaining the vacuum to allow deep impregnation into the ginger's cellular structure. Finally, pressure is gradually normalized, and the ginger is removed for drying and curing, producing a tender, intensely sweet candied ginger with superior texture and preservation.

Texture and Flavor Comparison

Traditional candying of ginger preserves a firm texture with a syrupy sweetness, while vacuum impregnation enhances flavor absorption and softens the texture more uniformly. Vacuum impregnation allows more intense and consistent ginger flavor infusion, resulting in a chewier and more flavorful product.

- Texture in Traditional Candying - Ginger pieces retain a denser, slightly fibrous texture due to gradual sugar penetration.

- Flavor in Traditional Candying - Flavor develops slowly, often resulting in balanced but milder ginger notes.

- Texture and Flavor in Vacuum Impregnation - Vacuum process enables deeper syrup infusion, producing softer texture and more concentrated ginger taste.

Efficiency and Time Considerations

Traditional candying of ginger involves prolonged soaking and simmering, often requiring several hours to achieve desired sweetness and texture, which can lead to nutrient loss and uneven sugar penetration. Vacuum impregnation candying significantly enhances efficiency by reducing processing time to under an hour, allowing rapid and uniform sugar infusion while preserving ginger's natural flavor and nutrients. This method's time-saving advantage and improved quality make it highly suitable for commercial production aiming at consistency and high throughput.

Related Important Terms

Osmotic Dehydration Gradient

Traditional candying of ginger relies on natural osmotic dehydration gradients to draw out moisture and infuse sugar slowly over time, often resulting in uneven sweetness and texture. Vacuum impregnation candying accelerates this process by applying pressure differences to enhance osmotic dehydration gradients, ensuring uniform sugar penetration and improved texture consistency in the finished product.

Vacuum Pulse Infusion

Vacuum Pulse Infusion enhances the candying of ginger by significantly improving syrup uptake and flavor penetration compared to traditional methods, reducing processing time while maintaining texture and nutrient retention. This advanced vacuum impregnation technique utilizes alternating vacuum and atmospheric pressure cycles to create microchannels in ginger tissues, ensuring uniform infusion and superior product quality.

Microstructural Crystallization Patterns

Traditional candying of ginger results in larger, irregular sugar crystals embedded within the fibrous tissue, leading to a coarser texture and slower sugar penetration, whereas vacuum impregnation candying promotes uniform microstructural crystallization with smaller, highly dispersed sugar crystals that enhance flavor infusion and preserve cellular integrity. Microscopic analysis reveals that vacuum impregnation induces concentrated sugar deposition within intracellular spaces, optimizing crystallization patterns that improve both texture and shelf life compared to conventional methods.

Tissue Porosity Enhancement

Vacuum impregnation candying significantly enhances tissue porosity in ginger by creating a controlled low-pressure environment that allows syrup to penetrate deeper into the cellular structure, resulting in more uniform sweetness and texture. Traditional candying relies on osmotic diffusion through intact tissues, limiting syrup absorption and leaving lower porosity and less consistent flavor distribution.

Solute Uptake Efficiency

Traditional candying of ginger relies on prolonged soaking in sugar syrup, resulting in moderate solute uptake efficiency due to limited penetration depth. Vacuum impregnation candying enhances solute uptake efficiency by creating pressure differentials that facilitate deeper and more uniform infusion of sugar into ginger tissues.

Moisture Migration Rate

Traditional candying of ginger involves slow moisture migration, resulting in uneven sugar penetration, while vacuum impregnation candying accelerates moisture migration rate by creating a pressure gradient that enhances uniform sugar absorption and shortens processing time. The increased moisture migration rate in vacuum impregnation preserves ginger's texture and flavor more effectively compared to the conventional method.

Cell Wall Integrity Preservation

Traditional candying of ginger often compromises cell wall integrity due to prolonged exposure to high temperatures, leading to textural softening and nutrient loss. Vacuum impregnation candying preserves cell wall structure by effectively infusing sugar solutions under low pressure, enhancing texture retention and maintaining the ginger's natural firmness.

Rapid Infusion Cycles

Rapid infusion cycles in vacuum impregnation candying significantly reduce processing time compared to traditional candying methods for ginger, enhancing flavor penetration and texture retention. This technique ensures uniform sugar absorption and moisture control, resulting in consistently high-quality candied ginger with improved shelf life.

Thermal Flavor Retention

Traditional candying of ginger relies on prolonged exposure to high temperatures, often causing significant loss of volatile flavor compounds, whereas vacuum impregnation candying uses reduced pressure to infuse sugar syrup at lower temperatures, enhancing thermal flavor retention by minimizing heat-induced degradation. This method preserves the ginger's natural aromatic profile while achieving a consistent sweetness and texture.

Traditional Candying vs Vacuum Impregnation Candying for ginger. Infographic

cookingdiff.com

cookingdiff.com