Candying and enrobing are two popular methods for preserving and enhancing confectionery fruit. Candying involves slowly cooking fruit in sugar syrup until fully infused, creating a chewy, sweet treat with a translucent appearance. Enrobing, on the other hand, coats fruit in a thin layer of chocolate or glaze, providing a smooth, flavorful outer shell while maintaining the fruit's natural texture inside.

Table of Comparison

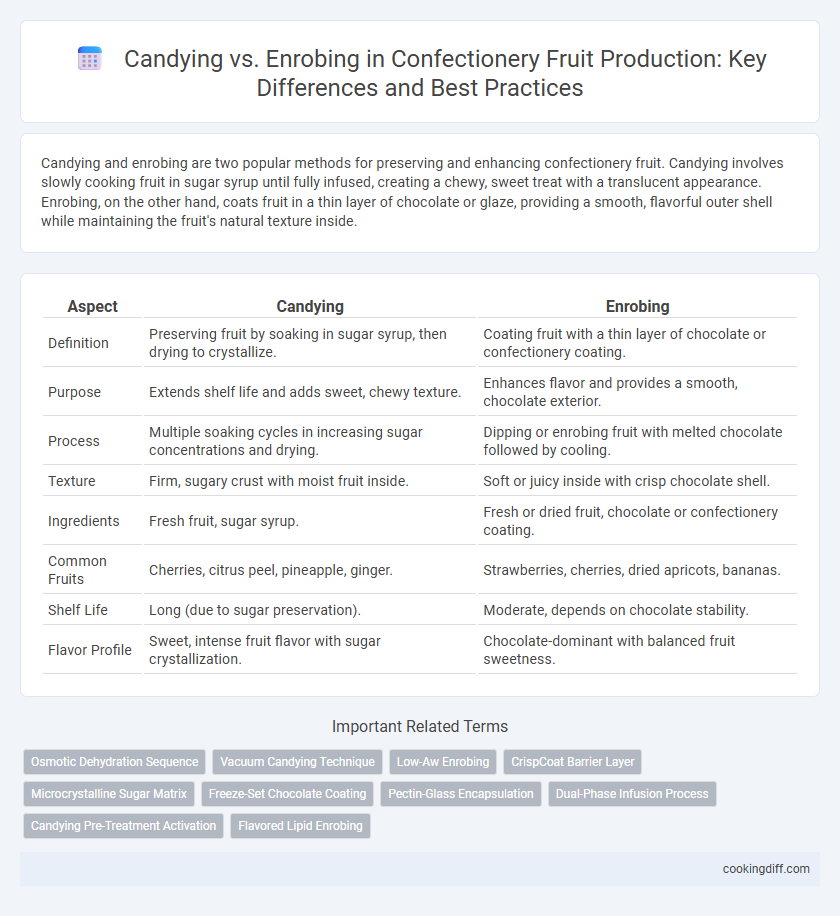

| Aspect | Candying | Enrobing |

|---|---|---|

| Definition | Preserving fruit by soaking in sugar syrup, then drying to crystallize. | Coating fruit with a thin layer of chocolate or confectionery coating. |

| Purpose | Extends shelf life and adds sweet, chewy texture. | Enhances flavor and provides a smooth, chocolate exterior. |

| Process | Multiple soaking cycles in increasing sugar concentrations and drying. | Dipping or enrobing fruit with melted chocolate followed by cooling. |

| Texture | Firm, sugary crust with moist fruit inside. | Soft or juicy inside with crisp chocolate shell. |

| Ingredients | Fresh fruit, sugar syrup. | Fresh or dried fruit, chocolate or confectionery coating. |

| Common Fruits | Cherries, citrus peel, pineapple, ginger. | Strawberries, cherries, dried apricots, bananas. |

| Shelf Life | Long (due to sugar preservation). | Moderate, depends on chocolate stability. |

| Flavor Profile | Sweet, intense fruit flavor with sugar crystallization. | Chocolate-dominant with balanced fruit sweetness. |

Introduction to Candying and Enrobing

Candying is a preservation technique that involves soaking fruit in sugar syrup until it becomes saturated with sugar, extending shelf life while enhancing sweetness. This process crystallizes the sugar around the fruit, creating a chewy texture with a glossy finish.

Enrobing, in contrast, involves coating fruit with a thin layer of chocolate or candy, offering a protective shell and rich flavor addition. Both methods are popular in confectionery but serve different purposes in texture and taste enhancement.

Historical Overview: Candying vs Enrobing in Confectionery

Candying and enrobing are two traditional methods used in confectionery for preserving and enhancing fruit. Candying dates back to ancient times, while enrobing gained prominence in the 20th century with advances in chocolate production.

- Candying Origins - Candying originated in the Middle Ages as a technique to preserve fruit using sugar syrup.

- Enrobing Development - Enrobing emerged in the early 1900s, involving coating fruit with chocolate to add flavor and texture.

- Historical Usage - Candying was historically used for long-term preservation, whereas enrobing focused on creating gourmet confections.

The Candying Process: Step-by-Step

How does the candying process differ from enrobing when preparing confectionery fruit? Candying involves slowly simmering fruit in sugar syrup until it becomes translucent and saturated with sweetness, preserving texture and flavor. Enrobing, by contrast, coats fruit with a layer of chocolate or candy, creating an external shell without altering the fruit's internal moisture and structure.

The Enrobing Technique: How It Works

Enrobing involves coating confectionery fruit with a thin layer of chocolate or syrup by passing it through a curtain of melted coating, ensuring an even and smooth finish. This technique creates a glossy exterior that protects the fruit and enhances flavor while preserving texture. Compared to candying, enrobing requires precise temperature control and specialized equipment to maintain coating consistency and quality.

Flavor and Texture Differences

| Flavor Differences | Candied fruits retain their natural sweetness enhanced by sugar infusion, resulting in a rich, intense fruit flavor. Enrobing adds a layer of chocolate or coating, imparting additional flavors such as cocoa bitterness or creaminess, which can mask or complement the fruit's original taste. Candied fruit flavor is pure and concentrated, whereas enrobed fruits offer a combined taste experience of fruit and coating. |

| Texture Differences | Candied fruits have a firm, chewy texture due to the crystallized sugar replacing moisture, providing a dense bite. Enrobed fruits are soft inside with a contrasting smooth or crunchy outer coating, offering a combination of tender fruit texture and crisp or creamy exterior. Candying produces a consistent chewiness, while enrobing delivers textural contrast in confectionery. |

Shelf Life and Preservation

Candying fruit involves soaking it in sugar syrup, which significantly extends shelf life by reducing moisture content and inhibiting microbial growth. Enrobing, which coats fruit with chocolate or candy, offers surface protection but less impact on internal preservation and shelf life. Candying provides superior preservation by penetrating the fruit, while enrobing mainly enhances flavor and aesthetics without long-term storage benefits.

Ingredient Selection for Candying and Enrobing

Candying requires selecting fruit with firm texture and high sugar content to withstand prolonged syrup immersion without disintegrating. Enrobing focuses on fruit quality that complements chocolate coatings, prioritizing moisture balance to prevent coating failure.

- Fruit firmness - Essential for candying to maintain shape during sugar crystallization processes.

- Sugar concentration - Key in candying to create a durable, sweet exterior that preserves fruit.

- Moisture content - Critical in enrobing to avoid chocolate bloom and ensure proper coating adhesion.

Choosing ingredients based on these factors optimizes texture and flavor in both candying and enrobing techniques for confectionery fruit.

Visual Appeal and Presentation

Candying enhances the natural texture and vibrant colors of fruit, creating a glossy, translucent finish that highlights the fruit's shape and details. This method allows the fruit to retain its original form, making it visually striking and ideal for decorative displays.

Enrobing coats the fruit in a smooth layer of chocolate or candy, offering a uniform appearance that emphasizes the coating rather than the fruit itself. The glossy finish of enrobing adds a polished look but can obscure the fruit's natural textures and colors.

Applications in Modern Confectionery

Candying preserves fruit by soaking it in sugar syrup, enhancing shelf life and texture, while enrobing involves coating fruit pieces with chocolate or candy shells for flavor and appearance. Both techniques play crucial roles in modern confectionery, offering diverse sensory experiences and product differentiation.

- Candying enhances preservation - Prolongs fruit shelf life through sugar crystallization, maintaining moisture and flavor.

- Enrobing adds texture and flavor contrast - Provides a crisp outer layer that complements the fruit's natural sweetness.

- Modern applications blend both methods - Innovative confectioners combine candying and enrobing to create premium, multi-textured fruit treats.

Related Important Terms

Osmotic Dehydration Sequence

Candying uses an osmotic dehydration sequence that gradually replaces fruit water content with concentrated sugar solutions, preserving texture and enhancing sweetness without compromising structural integrity. Enrobing involves coating fruit with chocolate or sugar, lacking the osmotic process, which results in a different texture and moisture retention compared to the candying method.

Vacuum Candying Technique

Vacuum candying enhances the infusion of sugar syrup into fruit by reducing pressure, allowing faster and deeper penetration compared to traditional enrobing, which primarily coats the surface with chocolate or sugar. This technique preserves the fruit's texture and flavor while achieving uniform sweetness without the thick outer layer typical of enrobed confections.

Low-Aw Enrobing

Low-Aw enrobing preserves confectionery fruit by maintaining water activity below 0.60, effectively inhibiting microbial growth and extending shelf life compared to traditional candying methods that rely on high sugar concentrations for preservation. This technique enhances texture and flavor retention while reducing the risk of crystallization, making it a preferred choice for high-quality fruit coatings in modern confectionery production.

CrispCoat Barrier Layer

Candying infuses fruit with sugar syrup to create a sweet, preserved interior while forming a CrispCoat Barrier Layer that prevents moisture migration and maintains texture. Enrobing coats fruit with chocolate or candy, which provides an external shell but lacks the internal moisture control and texture preservation offered by the CrispCoat Barrier Layer in candying.

Microcrystalline Sugar Matrix

Candying preserves fruit by saturating it with a microcrystalline sugar matrix that crystallizes to form a protective, stable barrier enhancing shelf life and texture. Enrobing involves coating fruit with a layer of chocolate or syrup without altering the internal sugar matrix, providing external flavor without the preservation benefits of candying.

Freeze-Set Chocolate Coating

Freeze-set chocolate coating in candying preserves the fruit's natural texture and flavor by rapidly solidifying the chocolate, unlike enrobing which can result in a softer, less distinct fruit center. This method enhances shelf life and provides a crisp, glossy finish that maintains the fresh fruit's integrity within confectionery products.

Pectin-Glass Encapsulation

Candying creates a pectin-glass encapsulation around confectionery fruit by infusing sugar syrup that crystallizes into a protective, translucent shell, preserving moisture and enhancing texture. In contrast, enrobing covers fruit with a chocolate or sugar coating that lacks the pectin-based structure, resulting in a less breathable, denser barrier without the extended preservation properties of candying.

Dual-Phase Infusion Process

The Dual-Phase Infusion Process in candying infuses fruit with sugar syrup in two stages, ensuring deep, uniform sweetness and extended shelf life, while preserving texture and natural flavor. Enrobing, by contrast, involves coating fruit with chocolate or sugar layers, which enhances external appeal but offers limited internal sweetness integration compared to candying's thorough infusion technique.

Candying Pre-Treatment Activation

Candying pre-treatment activation involves osmotic dehydration, which enhances sugar infusion and preserves fruit texture by controlling moisture loss before the candying process. This contrasts with enrobing, where the fruit is primarily coated with chocolate or sugar layers without altering internal moisture content or sugar saturation.

Candying vs Enrobing for confectionery fruit. Infographic

cookingdiff.com

cookingdiff.com