Choosing between a pot and a confectionery guitar for candying depends on precision and texture control. A confectionery guitar allows for accurate cutting of candy into uniform pieces, ensuring consistent thickness and shape. Using a pot for candying is essential for heating and melting ingredients evenly before shaping but lacks the cutting precision of a confectionery guitar.

Table of Comparison

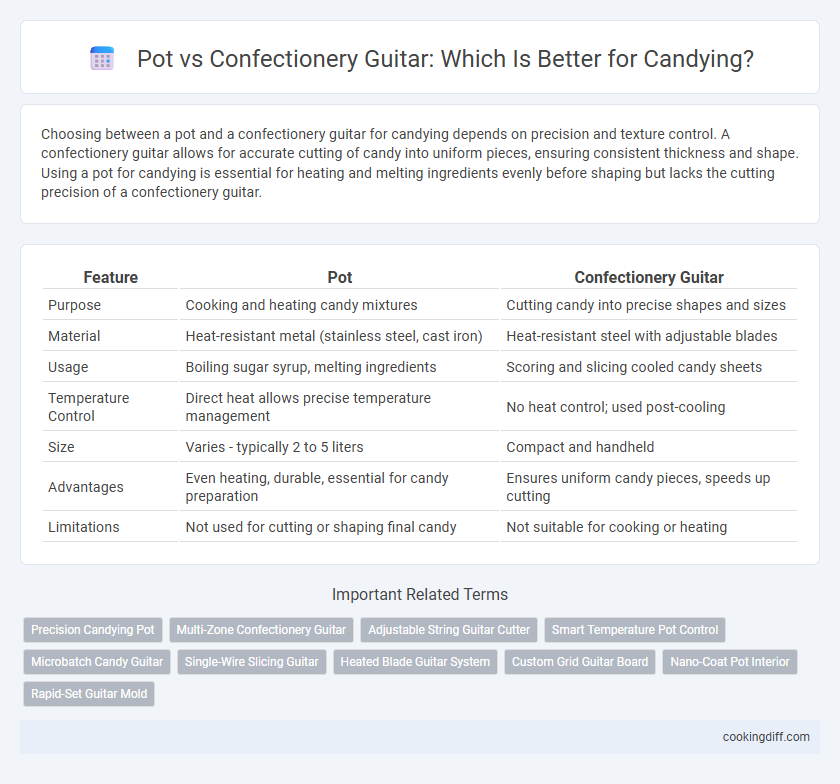

| Feature | Pot | Confectionery Guitar |

|---|---|---|

| Purpose | Cooking and heating candy mixtures | Cutting candy into precise shapes and sizes |

| Material | Heat-resistant metal (stainless steel, cast iron) | Heat-resistant steel with adjustable blades |

| Usage | Boiling sugar syrup, melting ingredients | Scoring and slicing cooled candy sheets |

| Temperature Control | Direct heat allows precise temperature management | No heat control; used post-cooling |

| Size | Varies - typically 2 to 5 liters | Compact and handheld |

| Advantages | Even heating, durable, essential for candy preparation | Ensures uniform candy pieces, speeds up cutting |

| Limitations | Not used for cutting or shaping final candy | Not suitable for cooking or heating |

Introduction to Candying: Pot vs Confectionery Guitar

Candying requires precise temperature control, which is why choosing between a pot and a confectionery guitar is crucial. A pot provides even heat distribution essential for boiling sugar solutions to the correct consistency.

A confectionery guitar is used to test sugar stages by measuring the thickness of syrup threads, ensuring the candy reaches the ideal texture. Both tools are fundamental in achieving perfect candy crystallization and flavor.

Understanding the Candying Process

Pot candying involves immersing fruit in a heated sugar syrup within a pot, allowing gradual absorption and crystallization to create a glossy texture. Confectionery guitar candying uses a flat, cooled sugar sheet that is cut and shaped, providing precise control over thickness and texture suitable for decorative purposes.

Understanding the candying process requires recognizing how temperature and syrup concentration influence sugar crystallization and moisture retention in candied products. The choice between pot and confectionery guitar methods affects the candy's appearance, texture, and application in confectionery art.

Traditional Pots: Features and Benefits

Traditional candying pots are crafted from high-quality materials like copper or stainless steel, ensuring even heat distribution essential for precise sugar cooking. These pots often feature thick bottoms that prevent scorching and maintain consistent temperature control during the candying process.

- Superior Heat Conductivity - Copper pots conduct heat evenly, reducing hot spots and preventing sugar from burning.

- Durability and Longevity - Stainless steel pots resist corrosion and maintain structural integrity through repeated use.

- Optimal Size and Depth - Traditional pots come in various sizes designed to accommodate different batch volumes for efficient candy preparation.

Confectionery Guitar: Overview and Functions

The Confectionery Guitar is an essential tool in candying, designed to precisely slice hardened sugar into uniform pieces. Its adjustable blades allow artisans to customize thickness, ensuring consistent texture and appearance in confections like lollipops and brittle. This device enhances productivity by providing clean, accurate cuts, making it superior to traditional pots for shaping hardened candy.

Pot Methods: Ideal Applications in Candying

Pot methods in candying provide precise temperature control essential for achieving the perfect sugar crystallization and texture. They are ideal for small-batch productions requiring consistent heat distribution and gradual cooking.

- Controlled Heating - Pots allow careful monitoring of temperature, reducing the risk of burning sugar.

- Small Batch Efficiency - Best suited for artisanal candy production where quality over quantity is prioritized.

- Versatility - Easily used for a variety of candy types including caramels, fudges, and hard candies.

Pot methods offer superior control for precise candying processes compared to confectionery guitars, which are more specialized for shaping candies.

Confectionery Guitar Techniques in Candy Production

Confectionery guitar techniques involve precise temperature control and timing to achieve the ideal sugar pull and thin, uniform candy sheets. This method is preferred over pot candying for creating delicate and intricate candy designs due to its superior consistency and texture.

Using a confectionery guitar allows candy makers to efficiently cut cooled sugar into perfect strips and shapes, enhancing production speed and aesthetic quality. The technique requires skillful manipulation of sugar's crystalline structure to prevent brittleness and ensure smooth, glossy finishes. Mastering these techniques is essential for producing high-quality artisanal candies and complex confectionery products.

Efficiency and Precision: Comparing Tools

Which tool offers better efficiency and precision for candying, a pot or a confectionery guitar? A pot provides consistent heat control essential for even cooking and sugar crystallization, reducing the risk of burning. The confectionery guitar advances precision by enabling clean, uniform sugar cuts, ideal for detailed candy designs and portioning.

Best Practices for Using Pots in Candying

Using the right pot is essential for effective candying as it ensures even heat distribution and prevents burning. Heavy-bottomed stainless steel pots are preferred to maintain temperature control and achieve consistent sugar crystallization.

- Choose heavy-bottomed pots - They provide uniform heat distribution, reducing the risk of hot spots that cause uneven candy texture.

- Use pots with a thick base - A thick base retains heat longer, allowing better temperature management during the candying process.

- Avoid nonstick coatings - Nonstick surfaces may interfere with proper sugar caramelization and can break down under high temperatures required for candying.

Enhancing Productivity with the Confectionery Guitar

| Enhancing productivity with the Confectionery Guitar involves precise cutting and portion control, drastically reducing candy waste compared to traditional pots. The Confectionery Guitar's adjustable wire spacing allows for consistent candy thickness, improving overall batch uniformity. This tool streamlines production processes, increasing output efficiency by enabling rapid slicing without compromising product quality. |

Related Important Terms

Precision Candying Pot

Precision candying pots provide superior temperature control and even heat distribution, essential for achieving perfect sugar crystallization and texture in confectionery guitar candying. Compared to traditional confectionery guitars, precision pots reduce the risk of scorching and improve consistency, making them the preferred choice for professional candy makers.

Multi-Zone Confectionery Guitar

Multi-zone confectionery guitars offer precise temperature control across different sections, ensuring uniform candy crystallization and preventing burning compared to single-zone pots. This technology enhances efficiency in candying processes by maintaining optimal heat distribution tailored to specific sugar mixtures.

Adjustable String Guitar Cutter

The Adjustable String Guitar Cutter offers precise control for candying by efficiently trimming sugar strands to consistent lengths, ensuring uniform texture and appearance. Its versatility surpasses traditional pot methods, optimizing confectionery production with customizable settings tailored to various candying techniques.

Smart Temperature Pot Control

Smart temperature pot control in candying ensures precise heat management, preventing sugar crystallization and achieving the perfect candy texture. Confectionery guitars lack this advanced feature, making temperature pots the superior choice for consistent, high-quality candy production.

Microbatch Candy Guitar

The Microbatch Candy Guitar offers superior temperature control and precision compared to traditional pot methods, ensuring consistent candy texture and flavor during the candying process. Its advanced heat distribution and durable construction make it ideal for small-batch confectionery production, enhancing efficiency and quality in artisanal candy crafting.

Single-Wire Slicing Guitar

The Single-Wire Slicing Guitar offers precise, uniform cuts essential for candying, ensuring consistent thickness and smooth edges compared to traditional pot methods. Its stainless steel wires maintain tension and hygiene, making it ideal for delicate confectionery tasks and improving overall product quality.

Heated Blade Guitar System

The Heated Blade Guitar System offers superior precision and temperature control compared to traditional pots, ensuring consistent candying results by evenly slicing through sugar masses without melting or sticking. Its advanced heating elements maintain optimal blade temperatures, enhancing efficiency and reducing waste in confectionery production.

Custom Grid Guitar Board

The Custom Grid Guitar Board in candying offers precise control over confectionery textures and shapes, outperforming traditional pots by ensuring consistent heat distribution and uniform candy crystallization. This advanced tool enhances efficiency and quality in confectionery production, enabling artisans to achieve intricate designs with superior structural integrity.

Nano-Coat Pot Interior

Nano-coat pot interiors provide superior non-stick properties and enhanced heat distribution, making them ideal for precise candying processes compared to traditional confectionery guitar instruments. This advanced coating ensures easy cleanup and prevents sugar crystallization, improving the quality and consistency of candy production.

Pot vs Confectionery Guitar for candying. Infographic

cookingdiff.com

cookingdiff.com