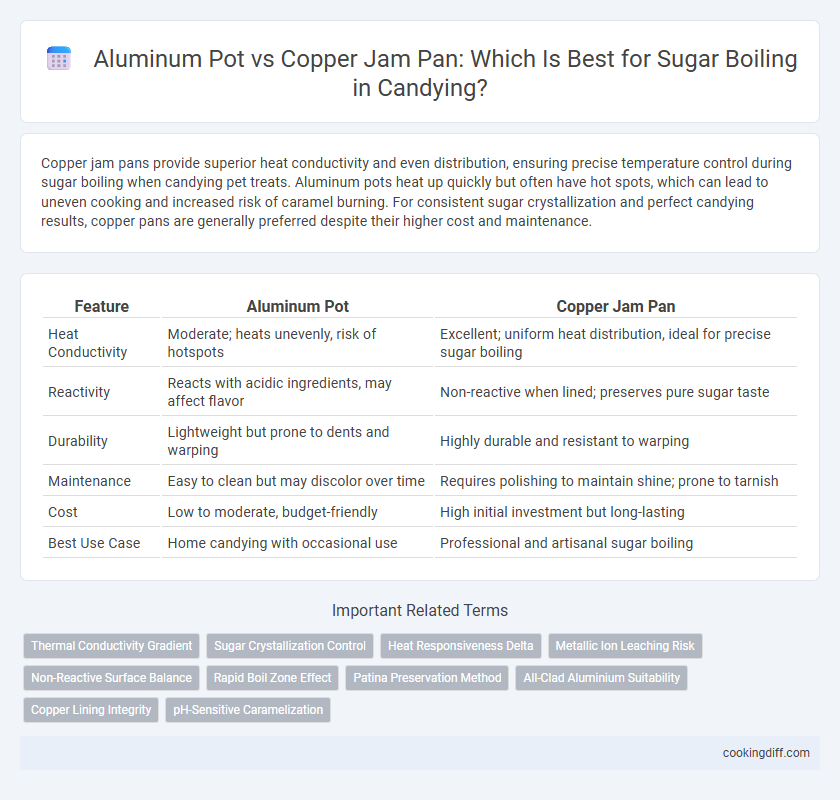

Copper jam pans provide superior heat conductivity and even distribution, ensuring precise temperature control during sugar boiling when candying pet treats. Aluminum pots heat up quickly but often have hot spots, which can lead to uneven cooking and increased risk of caramel burning. For consistent sugar crystallization and perfect candying results, copper pans are generally preferred despite their higher cost and maintenance.

Table of Comparison

| Feature | Aluminum Pot | Copper Jam Pan |

|---|---|---|

| Heat Conductivity | Moderate; heats unevenly, risk of hotspots | Excellent; uniform heat distribution, ideal for precise sugar boiling |

| Reactivity | Reacts with acidic ingredients, may affect flavor | Non-reactive when lined; preserves pure sugar taste |

| Durability | Lightweight but prone to dents and warping | Highly durable and resistant to warping |

| Maintenance | Easy to clean but may discolor over time | Requires polishing to maintain shine; prone to tarnish |

| Cost | Low to moderate, budget-friendly | High initial investment but long-lasting |

| Best Use Case | Home candying with occasional use | Professional and artisanal sugar boiling |

Introduction to Sugar Boiling: Why Pot Material Matters

Which pot material is best for sugar boiling in candying? Aluminum pots heat quickly but can cause uneven temperature distribution, affecting sugar consistency. Copper jam pans offer superior heat conductivity and precise temperature control, essential for achieving the perfect candy texture.

Aluminum Pots: Properties and Performance in Candying

Aluminum pots offer excellent heat conductivity, allowing for even sugar boiling and reducing the risk of hot spots that can cause burning in candying processes. Their lightweight nature ensures easier handling during the vigorous stirring required for sugar syrups. While aluminum reacts with acidic ingredients, protective coatings or anodized surfaces can enhance durability and maintain performance during candy making.

Copper Jam Pans: Traditional Favorite for Sugar Work

Copper jam pans are prized in candying for their superior heat conductivity, enabling even sugar boiling and precise temperature control essential for perfect candy texture. Their durability and quick response to heat changes make them favored tools among confectioners aiming for consistent, high-quality results.

Compared to aluminum pots, copper pans reduce hot spots, minimizing the risk of scorching sugar mixtures during boiling. The traditional use of copper in jam pans continues to support refined sugar work where temperature sensitivity is crucial for successful candying.

Heat Conductivity: Aluminum vs Copper in Sugar Boiling

| Metal | Heat Conductivity (W/m*K) | Impact on Sugar Boiling |

|---|---|---|

| Aluminum | 205 | Rapid and even heat distribution reduces hot spots, preventing sugar from burning during candying. |

| Copper | 401 | Superior heat conductivity provides precise temperature control, essential for achieving the perfect sugar caramelization. |

Reactivity with Sugar and Syrups: Safety and Taste Concerns

When candying, the reactivity of the pot material with sugar and syrups directly impacts both safety and flavor. Copper pans offer superior heat conductivity and minimal reactivity, preserving the taste, while aluminum pots may react with acidic ingredients, potentially altering flavor and leaching metals.

- Aluminum Reactivity - Aluminum can interact with acidic syrups, leading to a metallic taste and potential contamination.

- Copper Conductivity - Copper provides even heat distribution, reducing the risk of sugar crystallization and burnt flavors.

- Safety Considerations - Copper requires proper lining to prevent copper leaching, whereas aluminum pots often have protective coatings that can wear over time.

Weight and Handling: Ease of Use during Candying

Aluminum pots are lightweight, making them easier to handle during the candying process, especially when stirring thick sugar mixtures. Their low weight reduces fatigue, allowing for better control and precision while boiling sugar.

Copper jam pans are heavier but offer excellent heat conductivity, which can enhance temperature control despite their weight. However, the added weight may require more effort to maneuver, impacting ease of use during extended cooking sessions.

Cleaning and Maintenance: Longevity of Aluminum vs Copper

Aluminum pots require gentle cleaning to avoid scratching and maintain their non-reactive surface, which helps extend their lifespan during sugar boiling. Copper jam pans, although more durable, demand regular polishing to prevent tarnish and sustain their heat conductivity benefits in candying.

- Aluminum cleaning sensitivity - Harsh abrasives can damage aluminum, leading to quicker wear and reduced longevity.

- Copper maintenance needs - Frequent polishing is necessary to retain copper's aesthetic and functional qualities over time.

- Durability comparison - Copper pans generally last longer with appropriate upkeep, making them a preferred choice for consistent sugar boiling tasks.

Proper cleaning and maintenance routines significantly influence the lifespan and performance of both aluminum and copper cookware in candying.

Cost Comparison: Budgeting for Your Candying Equipment

Aluminum pots are more cost-effective for candying, offering a budget-friendly option without sacrificing basic heat conductivity essential for sugar boiling. Copper jam pans, while significantly pricier, provide superior thermal responsiveness and even heat distribution that can enhance precision in candy making. Investing in copper equipment may lead to better quality results but requires a higher initial budget compared to the durable, economical aluminum alternatives.

Suitability for Different Candy Recipes

Aluminum pots heat quickly and are suitable for general candying but may cause discoloration in delicate sugar recipes. Copper jam pans offer superior heat conductivity and precise temperature control, ideal for complex sugar boiling tasks like making soft caramels or nougats.

Copper's even heat distribution prevents hot spots, reducing the risk of burning while ensuring consistent texture in candies. Aluminum pans are lightweight and budget-friendly, suitable for firm candies or simple syrups but may react with acidic ingredients. For intricate candy recipes requiring exact temperature management, copper jam pans provide enhanced reliability and professional results.

Related Important Terms

Thermal Conductivity Gradient

Copper jam pans offer superior thermal conductivity with a gradient of approximately 401 W/m*K, enabling rapid and even heat distribution essential for precise sugar boiling in candying. Aluminum pots, with a thermal conductivity around 237 W/m*K, provide less uniform heat flow, increasing the risk of uneven caramelization and crystallization during sugar syrup preparation.

Sugar Crystallization Control

Copper jam pans offer superior thermal conductivity compared to aluminum pots, enabling more precise temperature control during sugar boiling, which is crucial for preventing premature crystallization and achieving a smooth candy texture. Aluminum pots, while more affordable, distribute heat less evenly, increasing the risk of hot spots that can cause uneven sugar crystallization and grainy candy results.

Heat Responsiveness Delta

Copper jam pans offer superior heat responsiveness due to their higher thermal conductivity, allowing rapid temperature changes essential for precise sugar boiling control in candying. Aluminum pots, with lower thermal conductivity, exhibit slower heat responsiveness, increasing the risk of uneven cooking and caramelization during sugar boiling.

Metallic Ion Leaching Risk

Aluminum pots pose a higher risk of metallic ion leaching during sugar boiling due to their reactive nature with acidic ingredients, which can affect candy quality and safety. Copper jam pans, although more expensive, offer superior heat conductivity and lower metallic ion contamination, making them safer for candying processes involving precise sugar temperature control.

Non-Reactive Surface Balance

Aluminum pots offer excellent heat conductivity but can react with acidic sugars, potentially altering flavor and color during candying, whereas copper jam pans provide a non-reactive surface that maintains the purity of the sugar mixture while ensuring even heat distribution. Copper's superior thermal responsiveness and chemical stability make it the preferred choice for precise sugar boiling and optimal candy texture.

Rapid Boil Zone Effect

Copper jam pans provide a superior rapid boil zone effect due to their excellent thermal conductivity, allowing sugar to heat evenly and reach precise temperatures quickly for optimal candying. In contrast, aluminum pots have slower heat distribution, increasing the risk of hot spots and uneven boiling during sugar cooking.

Patina Preservation Method

Copper jam pans offer superior heat conductivity essential for precise sugar boiling in candying, while aluminum pots require careful patina preservation methods to prevent reactive discoloration and maintain candy purity. Maintaining a consistent patina on aluminum cookware involves seasoning the surface regularly to create a non-reactive barrier, crucial for preventing metallic flavors and ensuring the quality of delicate sugar syrups.

All-Clad Aluminium Suitability

All-Clad aluminum pots provide excellent heat conductivity and even temperature distribution essential for precise sugar boiling in candying, reducing the risk of hot spots and crystallization. Compared to copper jam pans, All-Clad's aluminum suits candying tasks by combining durability, non-reactivity, and efficient heat control for consistent syrup results.

Copper Lining Integrity

Copper jam pans with solid copper lining offer superior heat conductivity essential for precise sugar boiling compared to aluminum pots, which may cause uneven heating. Maintaining the integrity of the copper lining is crucial to prevent contamination and ensure consistent temperature control during candying.

Aluminum Pot vs Copper Jam Pan for sugar boiling. Infographic

cookingdiff.com

cookingdiff.com