Sugar syrup candying preserves the natural flavor and texture of citrus peels by gently infusing sweetness, resulting in a glossy, tender treat with a rich, chewy consistency. Dehydrator candying removes moisture slowly, concentrating flavors and creating a firmer, more leathery texture without added sugars, ideal for a less sticky, more natural snack. Choosing between the two methods depends on desired sweetness and texture preferences, with syrup candying favoring indulgence and dehydrator candying offering a healthier, subtle option.

Table of Comparison

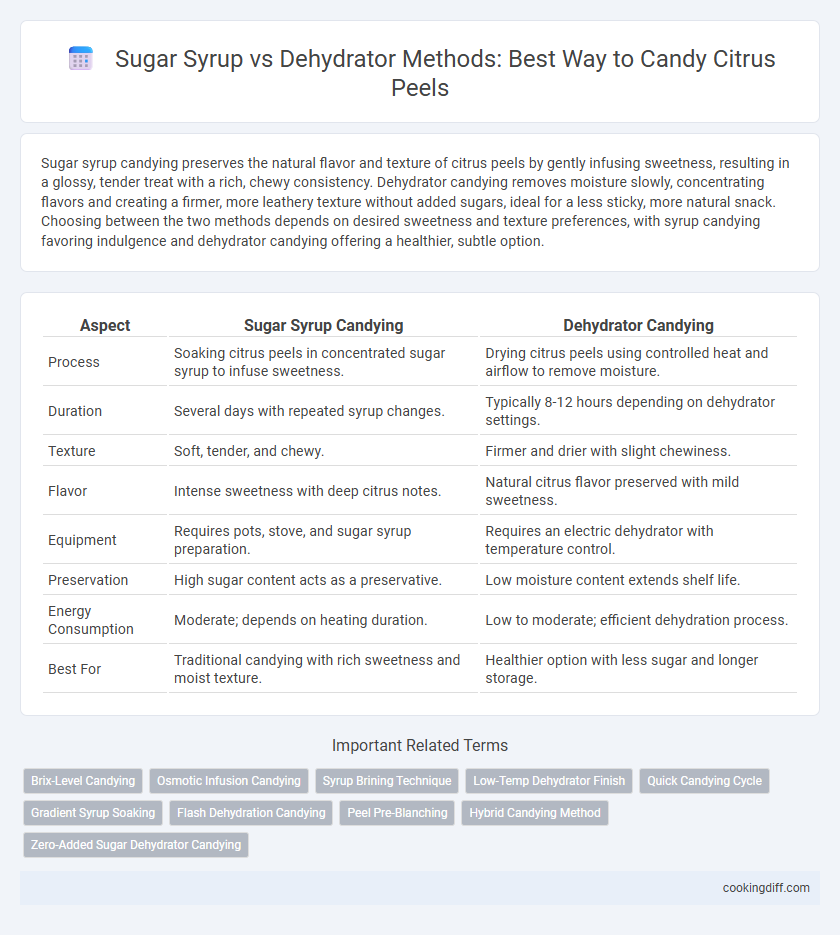

| Aspect | Sugar Syrup Candying | Dehydrator Candying |

|---|---|---|

| Process | Soaking citrus peels in concentrated sugar syrup to infuse sweetness. | Drying citrus peels using controlled heat and airflow to remove moisture. |

| Duration | Several days with repeated syrup changes. | Typically 8-12 hours depending on dehydrator settings. |

| Texture | Soft, tender, and chewy. | Firmer and drier with slight chewiness. |

| Flavor | Intense sweetness with deep citrus notes. | Natural citrus flavor preserved with mild sweetness. |

| Equipment | Requires pots, stove, and sugar syrup preparation. | Requires an electric dehydrator with temperature control. |

| Preservation | High sugar content acts as a preservative. | Low moisture content extends shelf life. |

| Energy Consumption | Moderate; depends on heating duration. | Low to moderate; efficient dehydration process. |

| Best For | Traditional candying with rich sweetness and moist texture. | Healthier option with less sugar and longer storage. |

Introduction to Candying Citrus Peels

| Sugar syrup candying involves soaking citrus peels in gradually concentrated sugar solutions, allowing the peels to absorb sweetness and achieve a tender, glossy finish. Dehydrator candying uses controlled low heat airflow to dry the peels slowly, preserving natural flavors and producing a chewier texture. Both methods transform bitter citrus rinds into flavorful confections, with sugar syrup offering a moist, saccharine coating and dehydrator candying emphasizing natural aromatic qualities. |

What is Sugar Syrup Candying?

Sugar syrup candying involves boiling citrus peels in a concentrated sugar solution, allowing the peels to absorb the syrup and develop a sweet, translucent coating. This traditional method enhances flavor and preserves the texture of the citrus peel over time.

The process requires gradual simmering and multiple syrup infusions to ensure thorough candying and even sweetness distribution. Compared to dehydrator candying, sugar syrup candying results in a softer, more tender peel with a glossy finish.

What is Dehydrator Candying?

Dehydrator candying is a method that uses low heat and airflow to dry citrus peels gradually, preserving their natural flavor and vibrant color. This technique reduces moisture content without submerging peels in syrup, resulting in a chewier texture compared to traditional sugar syrup candying. It offers a healthier alternative by minimizing added sugars while enhancing shelf life and maintaining the peels' essential oils.

Equipment Needed for Each Method

Sugar syrup candying requires basic stovetop equipment and cookware to simmer citrus peels in sugar solution until translucent. Dehydrator candying utilizes an electric food dehydrator to slowly remove moisture over hours, producing a chewier texture without added liquid.

- Sugar syrup candying - Requires a large pot or saucepan, a slotted spoon, and a cooling rack for draining peels.

- Sugar syrup candying - Needs a reliable heat source such as a gas or electric stove for consistent simmering.

- Dehydrator candying - Demands an electric food dehydrator with adjustable temperature controls for precise drying.

Step-by-Step Sugar Syrup Candying Process

The step-by-step sugar syrup candying process for citrus peels begins with blanching the peels to reduce bitterness, followed by simmering them in progressively concentrated sugar syrup. This gradual infusion allows the peels to absorb sweetness while retaining their texture and natural flavor.

After soaking, the peels are drained and either left to dry or gently boiled again to enhance syrup penetration. The final step involves coating the peels with granulated sugar for added texture and extended shelf life compared to dehydrator candying methods.

Step-by-Step Dehydrator Candying Process

How does the step-by-step dehydrator candying process improve the texture and flavor of citrus peels compared to sugar syrup candying? The dehydrator method gradually removes moisture by circulating warm air, preserving the natural citrus aroma and creating a chewier texture. This process minimizes sugar absorption, resulting in a less sticky and more intensely flavored candy peel.

Taste and Texture Differences

Sugar syrup candying infuses citrus peels with a sweet, moist texture, enhancing their rich, intense flavor. Dehydrator candying results in a chewier, less sugary peel with a more concentrated citrus taste due to slow moisture removal.

- Syrup candying - Peels absorb syrup, creating a glossy, tender, and sweeter treat.

- Dehydrator candying - Retains more peel bitterness, offering an aromatic, tangy profile with firmer texture.

- Texture contrast - Syrup method yields softness, while dehydrator produces chewiness and slight crispness.

The choice between methods depends on desired balance of sweetness and chewiness in candied citrus peels.

Nutritional Impact and Sugar Content

Sugar syrup candying increases the sugar content significantly, altering the nutritional profile of citrus peels by adding high levels of sucrose. Dehydrator candying preserves more natural nutrients and results in lower sugar content, making it a healthier option for retaining vitamins and fiber.

- Sugar Content - Sugar syrup candying infuses peels with dense sugar, often doubling the total sugar proportion compared to dehydrator methods.

- Nutritional Retention - Dehydrator candying maintains higher levels of vitamin C and antioxidants by avoiding prolonged sugar exposure and heat immersion.

- Caloric Impact - Candying in sugar syrup substantially raises the caloric value, whereas dehydrator candying keeps calories closer to that of raw citrus peels.

Storage and Shelf Life Comparison

Sugar syrup candying preserves citrus peels by infusing them with sugar, resulting in a longer shelf life of up to 6 months when stored in airtight containers at room temperature. Dehydrator candying removes moisture more thoroughly, extending shelf life beyond 12 months if kept in a cool, dry environment with low humidity. Proper storage conditions are crucial in both methods to prevent mold growth and maintain texture and flavor quality over time.

Related Important Terms

Brix-Level Candying

Sugar syrup candying involves soaking citrus peels in concentrated sugar solutions typically ranging from 60 to 70deg Brix, allowing gradual absorption and crystallization of sugar within the peel tissues. Dehydrator candying, by contrast, relies on low-temperature drying to reduce moisture without directly infusing sugar, resulting in lower Brix levels and a chewier texture compared to the sweeter, more translucent finish achieved through syrup candying.

Osmotic Infusion Candying

Sugar syrup candying uses concentrated sugar solutions to create osmotic infusion, drawing moisture out of citrus peels while infusing them with sweetness and preserving texture, resulting in a glossy, tender product. Dehydrator candying relies on low heat airflow for moisture removal without sugar infusion, producing a chewier peel with less sweetness and a drier surface.

Syrup Brining Technique

Sugar syrup candying preserves citrus peel flavor by immersing it in a concentrated syrup solution, promoting thorough sugar infusion and yielding a tender, glossy texture; this method controls crystallization and enhances sweetness more effectively than dehydrator candying. Syrup brining technique involves gradual syrup concentration adjustments that prevent peel shrinkage and maintain moisture, ensuring a consistent, high-quality candied product.

Low-Temp Dehydrator Finish

Sugar syrup candying preserves citrus peels by infusing them with a concentrated sugar solution, enhancing sweetness and texture, while low-temp dehydrator candying gradually removes moisture at controlled temperatures below 140degF to maintain natural flavors and vibrant colors. The low-temp dehydrator finish ensures evenly dried peels with a chewy yet tender bite, preventing caramelization and preserving essential oils for superior aromatic quality.

Quick Candying Cycle

Sugar syrup candying preserves citrus peels by infusing them with a concentrated sucrose solution, resulting in a glossy finish and enhanced sweetness within a quick candying cycle of 4-6 hours. Dehydrator candying removes moisture through controlled low heat over 8-12 hours, yielding a chewier texture but requiring a longer processing time compared to the sugar syrup method.

Gradient Syrup Soaking

Gradient syrup soaking in sugar syrup candying gradually infuses citrus peels with sweetness and moisture, preserving their vibrant texture and enhancing flavor complexity through controlled sugar concentration stages. Dehydrator candying bypasses syrup absorption, resulting in drier peels with a firmer bite but less integrated sweetness and flavor depth compared to the progressive infusion achieved by gradient syrup soaking.

Flash Dehydration Candying

Flash dehydration candying of citrus peels preserves vibrant color and intense flavor by rapidly removing moisture at high temperatures, minimizing cell damage compared to traditional sugar syrup candying. This method enhances texture with a crisp exterior and concentrated sweetness, offering a more efficient, shelf-stable alternative to prolonged immersion in sugar syrup.

Peel Pre-Blanching

Peel pre-blanching in sugar syrup candying softens citrus peels and reduces bitterness by leaching out pith components, enhancing syrup penetration and final texture. In contrast, dehydrator candying skips blanching, preserving more natural peel bitterness but resulting in a firmer, chewier texture due to moisture retention differences.

Hybrid Candying Method

The hybrid candying method combines the precise sugar syrup infusion of traditional candying with the controlled dehydration process of a dehydrator to achieve optimal texture and flavor retention in citrus peels. This approach enhances sugar crystallization while preserving the peel's natural aroma, resulting in superior-quality candied citrus with balanced sweetness and chewiness.

Sugar Syrup Candying vs Dehydrator Candying for citrus peels. Infographic

cookingdiff.com

cookingdiff.com