Copper pans provide superior heat conductivity and precise temperature control, essential for candying to avoid burning sugar. Nonstick induction pans offer convenience and easy cleanup but may heat less evenly, increasing the risk of hot spots. For consistent, expert candying results, copper pans remain the preferred choice despite requiring more maintenance.

Table of Comparison

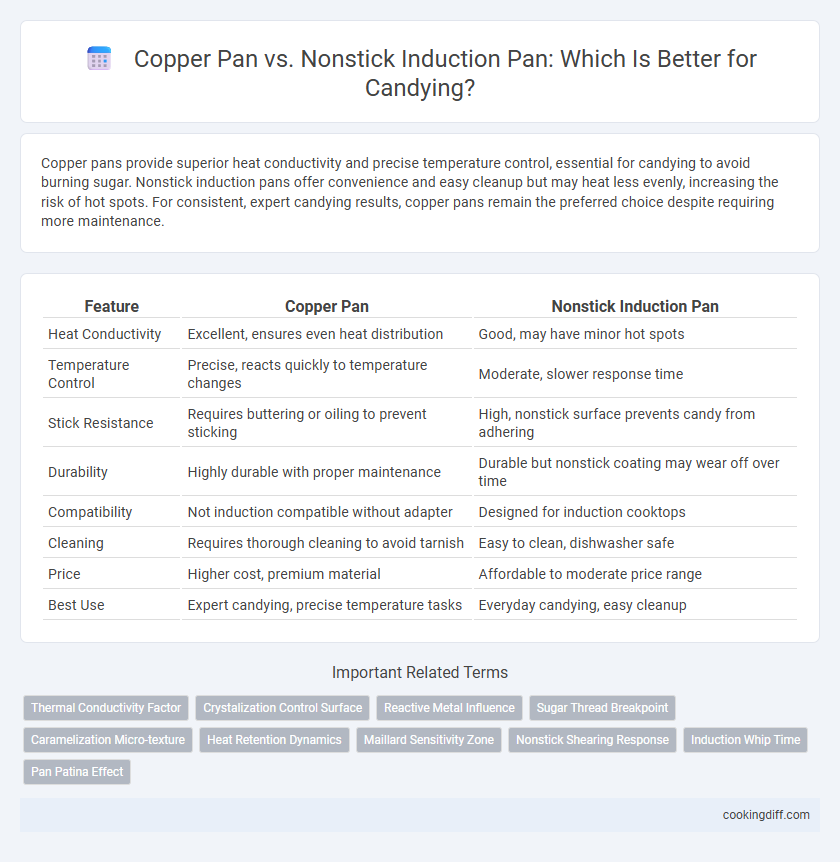

| Feature | Copper Pan | Nonstick Induction Pan |

|---|---|---|

| Heat Conductivity | Excellent, ensures even heat distribution | Good, may have minor hot spots |

| Temperature Control | Precise, reacts quickly to temperature changes | Moderate, slower response time |

| Stick Resistance | Requires buttering or oiling to prevent sticking | High, nonstick surface prevents candy from adhering |

| Durability | Highly durable with proper maintenance | Durable but nonstick coating may wear off over time |

| Compatibility | Not induction compatible without adapter | Designed for induction cooktops |

| Cleaning | Requires thorough cleaning to avoid tarnish | Easy to clean, dishwasher safe |

| Price | Higher cost, premium material | Affordable to moderate price range |

| Best Use | Expert candying, precise temperature tasks | Everyday candying, easy cleanup |

Introduction to Candying Techniques

Copper pans offer superior heat conductivity, crucial for precise temperature control in candying techniques. Their responsiveness helps prevent sugar crystallization and ensures even caramelization.

Nonstick induction pans provide convenience with easy cleanup and compatibility with modern stovetops. However, they may lack the even heat distribution that copper pans deliver for delicate candying processes.

Importance of Cookware in Candying

The choice of cookware significantly impacts candying, as copper pans offer superior heat conductivity and precise temperature control essential for sugar cooking. Nonstick induction pans provide even heating but may lack the responsiveness needed to prevent scorching during delicate sugar stages.

Copper pans quickly adjust to temperature changes, reducing the risk of crystallization and ensuring smooth caramelization. Nonstick induction pans are easier to clean but may require careful monitoring to maintain consistent heat for perfect candy texture.

Overview of Copper Pans

What makes copper pans ideal for candying compared to nonstick induction pans? Copper pans offer superior heat conductivity, allowing precise temperature control essential for achieving the perfect candy texture. Their rapid heat response prevents sugar from burning, unlike some nonstick induction pans that may have slower heat distribution.

Overview of Nonstick Induction Pans

Nonstick induction pans offer excellent heat distribution and precise temperature control, essential for candying delicate sugars. Their smooth, coated surface prevents sticking and simplifies cleanup while maintaining consistent cooking performance.

- Heat Efficiency - Designed to work with induction cooktops, these pans quickly and evenly distribute heat to avoid hot spots during candying.

- Nonstick Surface - The coating minimizes sugar adhesion, reducing the risk of burning or crystallization in candy preparations.

- Durability - High-quality nonstick induction pans resist scratching and wear, ensuring reliable performance over multiple candying sessions.

Heat Conductivity: Copper vs Nonstick Induction

Copper pans offer superior heat conductivity, allowing precise temperature control essential for candying, while nonstick induction pans heat more unevenly, potentially causing hot spots. This difference affects the consistency and texture of the candy, making copper pans a preferred choice for delicate sugar work.

- Copper pans conduct heat rapidly - They provide consistent temperature distribution, minimizing the risk of burning sugar.

- Nonstick induction pans rely on magnetic induction - This can lead to slower and less even heating compared to copper.

- Heat control precision in copper pans - Enables better management of candy stages like soft ball and hard crack.

Copper pans enhance candying outcomes through superior thermal conductivity and precise heat management.

Temperature Control and Precision

Copper pans provide superior temperature control for candying due to their excellent thermal conductivity, allowing precise adjustments and reducing the risk of burning sugar. Nonstick induction pans offer convenience but may lack the fine temperature precision required for delicate candy-making processes.

- Copper Pan Heat Response - Copper quickly and evenly distributes heat, enabling exact temperature adjustments critical for candying stages.

- Nonstick Induction Convenience - Nonstick surfaces prevent sticking and are easy to clean, but temperature changes may be slower and less precise on induction models.

- Temperature Precision Impact - Precise control in copper pans helps avoid crystallization and results in smoother candy texture compared to nonstick induction pans.

Caramelization and Sugar Reaction Differences

| Pan Type | Caramelization Quality | Sugar Reaction Behavior |

|---|---|---|

| Copper Pan | Provides superior heat conductivity, ensuring even caramelization and preventing hot spots that cause burning. | Facilitates precise temperature control, resulting in smoother sugar melting and consistent Maillard reactions. |

| Nonstick Induction Pan | Offers moderate heat distribution but can create uneven caramelization, increasing risk of sugar crystallization. | Nonstick surface reduces sticking, but less thermal responsiveness may lead to variable sugar reactions and harder caramel texture. |

Ease of Cleaning and Maintenance

Copper pans offer excellent heat conductivity, making candying precise but require regular polishing to maintain their appearance and prevent tarnishing. Nonstick induction pans provide an easier cleaning experience due to their smooth, coated surface that resists sticky residues typically formed in candying. Maintenance for nonstick pans is simpler and less time-consuming, although their coating may degrade with frequent high-heat use compared to the durability of copper.

Safety Considerations for Candying

Copper pans provide excellent heat conductivity, allowing precise temperature control essential for safe candying, which reduces the risk of burning sugar or causing hot spots. Nonstick induction pans offer even heating surfaces but may not withstand the high temperatures required for candying, potentially releasing harmful fumes if overheated.

Using copper pans minimizes the chance of sudden temperature fluctuations, ensuring consistent cooking and safer sugar caramelization. Nonstick induction pans require careful monitoring to avoid overheating, as the coating can degrade under intense heat, posing health risks. Proper utensil selection and temperature control are critical for preventing accidents and ensuring food safety during the candying process.

Related Important Terms

Thermal Conductivity Factor

Copper pans offer superior thermal conductivity, allowing precise temperature control essential for candying processes, while nonstick induction pans generally have lower thermal conductivity, resulting in slower and less uniform heat distribution. Optimal candying requires consistent heat to prevent crystallization, making copper pans a preferred choice for expert confectioners.

Crystalization Control Surface

Copper pans offer superior crystallization control for candying due to their excellent thermal conductivity, promoting even heat distribution and precise temperature management. Nonstick induction pans, while convenient, may create uneven heat spots that hinder consistent sugar crystallization, affecting the final texture and gloss of candies.

Reactive Metal Influence

Copper pans, known for their excellent thermal conductivity, facilitate precise temperature control essential in candying, but their reactive metal nature can interact with acidic ingredients, potentially affecting flavor. Nonstick induction pans, typically made from inert materials, prevent chemical reactions during cooking, ensuring flavor purity while offering efficient heat distribution on induction cooktops.

Sugar Thread Breakpoint

Copper pans provide superior thermal conductivity and precise temperature control, which minimizes the risk of sugar thread breakpoint during candying. Nonstick induction pans heat unevenly, increasing the likelihood of sugar crystallization and thread breakage when forming delicate sugar threads.

Caramelization Micro-texture

Copper pans provide exceptional thermal conductivity, enabling precise temperature control essential for even caramelization and achieving a superior micro-texture in candying. Nonstick induction pans offer ease of use but may result in less uniform heat distribution, potentially affecting the fine crystalline structure and gloss of caramelized sugar.

Heat Retention Dynamics

Copper pans exhibit superior heat retention and rapid temperature adjustments essential for precise candying, due to copper's high thermal conductivity of approximately 400 W/m*K. Nonstick induction pans, often made from stainless steel with lower thermal conductivity around 15-25 W/m*K, provide less efficient heat retention but offer even heat distribution and easy release, impacting the consistency and quality of candy-making processes.

Maillard Sensitivity Zone

Copper pans provide superior temperature control essential for maintaining the Maillard sensitivity zone, enabling precise caramelization and browning during candying. Nonstick induction pans often lack the thermal responsiveness required to consistently sustain this critical temperature range, potentially resulting in uneven flavor development.

Nonstick Shearing Response

Nonstick induction pans offer superior shearing resistance during candying, preventing sugar crystals from sticking and burning, which ensures consistent caramelization and easy cleanup. Copper pans, while excellent for heat conductivity, often lack the nonstick surface that minimizes residue buildup and shearing issues in high-sugar environments.

Induction Whip Time

Copper pans offer precise temperature control and rapid heat conductivity, which can reduce candying whip time by maintaining consistent sugar temperatures. Nonstick induction pans, while convenient for cleanup, often require longer whip times due to slower heat response and uneven temperature distribution.

Copper Pan vs Nonstick Induction Pan for candying. Infographic

cookingdiff.com

cookingdiff.com