Candying involves slowly cooking food in sugar syrup to preserve flavor and texture, creating a sweet, chewy treat ideal for desserts or garnishes. Freeze-dry candying removes moisture through sublimation, maintaining the original shape and concentrating flavors while producing a crispy, lightweight texture perfect for snacking or plating. Both methods enhance food preservation but differ in texture and moisture content, influencing their culinary applications.

Table of Comparison

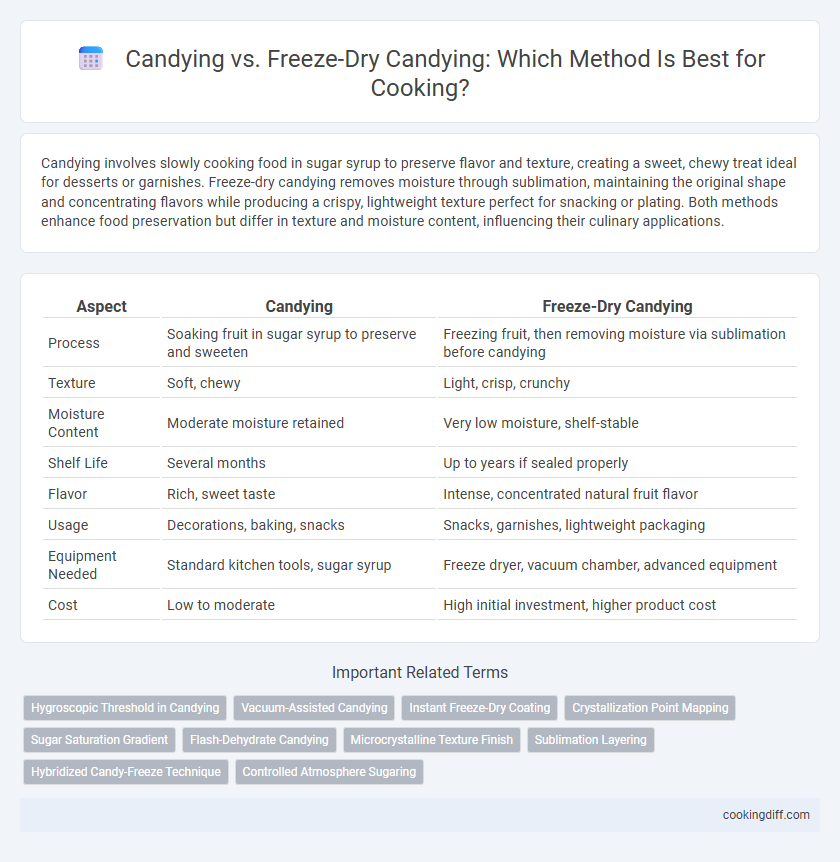

| Aspect | Candying | Freeze-Dry Candying |

|---|---|---|

| Process | Soaking fruit in sugar syrup to preserve and sweeten | Freezing fruit, then removing moisture via sublimation before candying |

| Texture | Soft, chewy | Light, crisp, crunchy |

| Moisture Content | Moderate moisture retained | Very low moisture, shelf-stable |

| Shelf Life | Several months | Up to years if sealed properly |

| Flavor | Rich, sweet taste | Intense, concentrated natural fruit flavor |

| Usage | Decorations, baking, snacks | Snacks, garnishes, lightweight packaging |

| Equipment Needed | Standard kitchen tools, sugar syrup | Freeze dryer, vacuum chamber, advanced equipment |

| Cost | Low to moderate | High initial investment, higher product cost |

Introduction to Candying and Freeze-Dry Candying

What distinguishes traditional candying from freeze-dry candying in cooking? Candying involves preserving fruits or vegetables by soaking them in sugar syrup, which enhances flavor and extends shelf life. Freeze-dry candying removes moisture through freezing and vacuum drying, maintaining texture and nutritional content more effectively.

What is Traditional Candying?

Traditional candying is a preservation technique that involves soaking fruits or vegetables in sugar syrup until they become saturated and infused with sweetness. This method enhances flavor and texture while extending shelf life by preventing microbial growth.

Unlike freeze-dry candying, traditional candying relies on the gradual absorption of sugar through simmering and drying processes, maintaining a chewy consistency. It is commonly used for citrus peels, cherries, and ginger in cooking and baking applications.

Understanding Freeze-Dry Candying

Freeze-dry candying involves removing moisture from fruits or other ingredients through a low-temperature vacuum process, preserving flavor and texture more effectively than traditional candying. This method enhances shelf life and maintains nutritional value by preventing microbial growth without using high heat.

Understanding freeze-dry candying reveals its benefits in retaining the original color and taste of the food, making it ideal for gourmet cooking and baking. Unlike conventional candying, which relies on sugar absorption and heat, freeze-drying produces a lighter, crispier texture. This technique allows chefs to create unique, intense flavor profiles while minimizing added sugars and preservatives.

Key Differences Between Candying and Freeze-Dry Candying

Candying involves soaking fruit in sugar syrup to preserve and sweeten it, resulting in a chewy texture and glossy finish. Freeze-dry candying removes moisture through sublimation, maintaining the fruit's original shape and nutrients while creating a light, crispy texture. Key differences include moisture content, texture, and preservation methods, with candying relying on sugar saturation and freeze-dry candying utilizing low-temperature dehydration.

Ingredients and Equipment Required

Candying requires sugar, water, and fresh fruits or vegetables, along with basic equipment like a saucepan and a candy thermometer to achieve proper syrup consistency. Freeze-dry candying involves using ingredients similar to traditional candying but necessitates specialized freeze-drying equipment to remove moisture while preserving flavor and texture. The freeze-drying process also demands precise temperature control and vacuum chambers, making it more equipment-intensive compared to candying.

Step-by-Step Candying Process

Candying involves simmering fruit in sugar syrup until fully infused, preserving texture and flavor through gradual absorption. Freeze-dry candying removes moisture by sublimation after freezing, retaining shape and intensifying natural sweetness without altering texture.

- Preparation - Select fresh fruit and trim it to uniform pieces for even candying or freeze-drying.

- Syrup Cooking - For candying, simmer fruit in gradually concentrated sugar syrup; for freeze-dry candying, freeze fruit before placing in the freeze-dryer.

- Drying and Storage - Candying requires drying fruit in air or low heat; freeze-dry candying completes dehydration through vacuum drying to ensure long shelf life.

Freeze-Dry Candying: Preparation and Techniques

Freeze-dry candying preserves the natural flavor and texture of fruits by removing moisture through a vacuum freezing process, unlike traditional candying that relies on sugar syrup absorption. This technique enhances shelf life and nutritional retention, making it ideal for gourmet cooking and long-term storage.

- Vacuum Freezing - Rapidly freezes the fruit to lock in cellular structure before moisture extraction.

- Sublimation Process - Converts frozen water into vapor without melting, preserving flavor intensity.

- Minimal Sugar Use - Maintains fruit's natural sweetness, reducing added sugar content in recipes.

Freeze-dry candying offers a modern, efficient alternative to traditional candying with superior preservation and culinary benefits.

Flavor and Texture Comparison

Candying preserves the natural moisture of fruits, resulting in a rich, chewy texture and intensified sweetness that enhances flavor complexity. Freeze-dry candying removes moisture through sublimation, yielding a light, crisp texture with concentrated fruit flavors that burst with each bite.

The traditional candying method enhances caramelization, contributing to deeper, more robust taste profiles ideal for baking and confectionery. Freeze-dry candying maintains the fruit's original shape and nutrients, providing a healthier option with a distinct, airy crunch perfect for snacking or garnishing.

Uses in Culinary Applications

| Candying | Preserves fruits by infusing sugar, commonly used for garnishing desserts, flavoring pastries, and enhancing texture in confections. |

| Freeze-Dry Candying | Retains original flavor and nutrients by removing moisture through sublimation, ideal for lightweight toppings, snack additives, and long shelf-life ingredients. |

Related Important Terms

Hygroscopic Threshold in Candying

Candying preserves fruit by saturating it with sugar, creating a hygroscopic barrier that prevents moisture absorption and spoilage, while freeze-dry candying removes water content to achieve a low hygroscopic threshold for extended shelf life. The hygroscopic threshold in candying determines the candy's ability to resist moisture uptake, vital for texture and preservation in culinary applications.

Vacuum-Assisted Candying

Vacuum-assisted candying enhances flavor infusion and preserves vibrant colors by reducing pressure to draw syrup deeper into the food, contrasting with freeze-dry candying that primarily removes moisture to create a crispy texture. This method optimizes sugar penetration and texture retention, making it ideal for delicate fruits and precise culinary applications.

Instant Freeze-Dry Coating

Instant freeze-dry coating preserves the vibrant colors and intense flavors of candied fruits by rapidly removing moisture without the heat damage typical of traditional candying, resulting in a crunchy texture and extended shelf life. This method enhances nutrient retention and reduces stickiness compared to conventional candying, making it ideal for gourmet cooking applications and premium confectionery products.

Crystallization Point Mapping

Candying involves saturating fruit or vegetables in sugar syrup to replace water content, relying on precise crystallization point mapping to control sugar concentration and texture. Freeze-dry candying preserves the structural integrity through sublimation but lacks the controlled crystallization critical for traditional candying's characteristic crystalline texture.

Sugar Saturation Gradient

Candying creates a high sugar saturation gradient by gradually infusing moisture with concentrated sugar, resulting in a dense, chewy texture that preserves flavor and color. Freeze-dry candying, however, maintains a lower sugar saturation gradient by removing moisture through sublimation, producing a lighter, crispier product with a more delicate concentration of sugars.

Flash-Dehydrate Candying

Flash-dehydrate candying preserves the vibrant flavor and texture of fruits by rapidly removing moisture without crystallization, making it superior to traditional candying and freeze-dry candying methods. This technique enhances culinary applications by maintaining structural integrity and intensifying natural sweetness, ideal for gourmet cooking and high-quality dessert creations.

Microcrystalline Texture Finish

Candying produces a dense, microcrystalline texture finish by slowly infusing sugar, resulting in a glossy, chewy surface ideal for decorative baking. Freeze-dry candying retains the original flavor but generates a porous, brittle texture with less microcrystalline structure, enhancing crispness rather than chewiness.

Sublimation Layering

Candying enhances flavor and texture by immersing ingredients in sugar syrup, creating a dense, sweet coating, while freeze-dry candying uses sublimation layering to remove moisture through freezing and vacuum pressure, preserving shape and intensifying flavor concentration without added sugar. Sublimation layering in freeze-dry candying maintains cellular structure and extends shelf life, making it ideal for gourmet cooking applications.

Hybridized Candy-Freeze Technique

The hybridized candy-freeze technique combines the traditional candying process with freeze-drying technology to preserve texture and intensify flavor by removing moisture while infusing sugar. This method enhances shelf life and maintains the natural color and nutrients of fruits more effectively than conventional candying or freeze-drying alone.

Candying vs Freeze-Dry Candying for cooking. Infographic

cookingdiff.com

cookingdiff.com