Using a cooling rack for candying allows air to circulate evenly around the candy, promoting consistent drying and preventing sticky bottoms. Dehydrator trays offer a controlled environment with adjustable temperature settings, ensuring precise moisture removal and preserving flavor. Choosing between the two depends on your preference for natural airflow versus regulated heat control during the candying process.

Table of Comparison

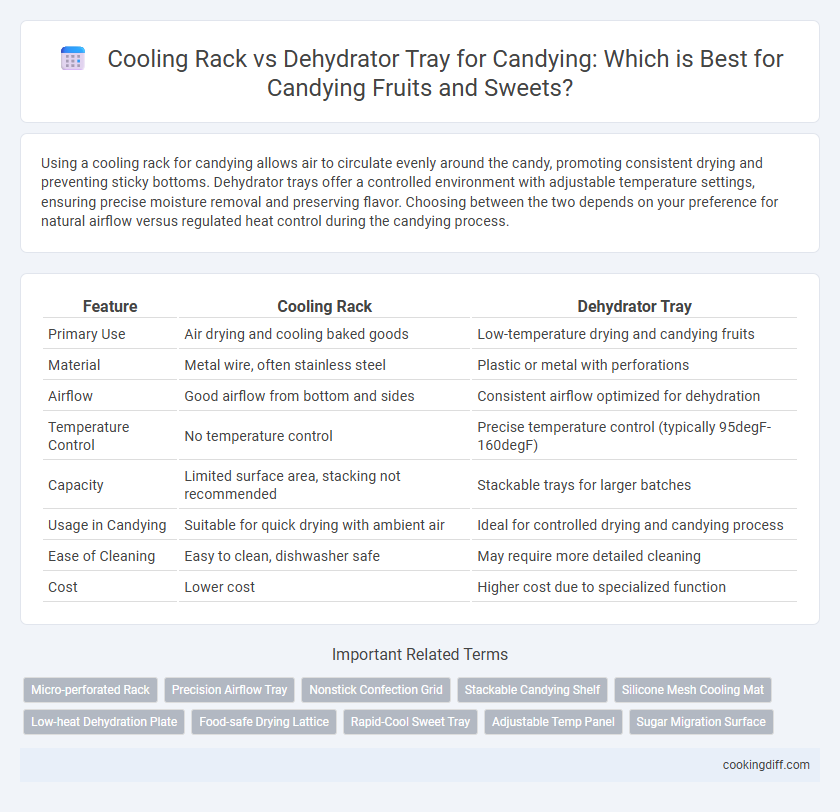

| Feature | Cooling Rack | Dehydrator Tray |

|---|---|---|

| Primary Use | Air drying and cooling baked goods | Low-temperature drying and candying fruits |

| Material | Metal wire, often stainless steel | Plastic or metal with perforations |

| Airflow | Good airflow from bottom and sides | Consistent airflow optimized for dehydration |

| Temperature Control | No temperature control | Precise temperature control (typically 95degF-160degF) |

| Capacity | Limited surface area, stacking not recommended | Stackable trays for larger batches |

| Usage in Candying | Suitable for quick drying with ambient air | Ideal for controlled drying and candying process |

| Ease of Cleaning | Easy to clean, dishwasher safe | May require more detailed cleaning |

| Cost | Lower cost | Higher cost due to specialized function |

Introduction: Cooling Rack vs Dehydrator Tray in Candying

Cooling racks and dehydrator trays serve distinct roles in the candying process, influencing texture and drying efficiency. Cooling racks allow air circulation beneath the candy, preventing sogginess and promoting even crispness.

Dehydrator trays maintain consistent low temperatures with controlled airflow, ideal for precise moisture removal and long drying times. Choosing the right tool depends on the candy type and desired end texture, with dehydrator trays offering superior control for intricate candying tasks.

What is a Cooling Rack?

A cooling rack is a grid-like metal frame designed to elevate candy or baked goods, allowing air to circulate evenly and prevent sogginess during the cooling or drying process. It is commonly used in candying to ensure consistent texture by promoting moisture evaporation.

- Material - Typically made from stainless steel or chrome-plated steel to resist heat and corrosion.

- Design - Features an open grid structure that supports items while maximizing airflow underneath.

- Usage - Ideal for drying candied fruits or cooling sugar-coated confections without trapping moisture.

What is a Dehydrator Tray?

| Dehydrator Tray | A dehydrator tray is a flat, perforated surface used in food dehydrators to facilitate even air circulation, essential for drying fruits, vegetables, and candying ingredients efficiently. Unlike cooling racks, dehydrator trays are specifically designed to fit into dehydrators, optimizing moisture removal without the need for manual flipping or moving. This design accelerates the candying process by maintaining consistent temperature and airflow, enhancing texture and shelf-life of candied products. |

Key Features: Cooling Rack for Candying

Cooling racks provide superior airflow during the candying process, allowing evenly distributed air to prevent sticky, uneven surfaces. Their sturdy metal grids also support delicate candies without bending or warping under weight.

- Optimal Air Circulation - Cooling racks feature open grids that enable full airflow around candies for consistent drying and texture.

- Durable Construction - Made of stainless steel or chrome-plated metal, cooling racks resist heat and maintain shape under heavy loads.

- Versatile Usage - Suitable for cooling, drying, and displaying a variety of candied fruits and confections with minimal sticking.

Key Features: Dehydrator Tray for Candying

A dehydrator tray offers superior airflow and even heat distribution, essential for achieving consistent candying results. Its stackable design allows processing multiple batches simultaneously, optimizing efficiency.

Cooling racks, while useful, often lack the precise temperature control and moisture removal capabilities found in dehydrator trays. Dehydrator trays are specifically engineered to maintain low temperatures and optimal humidity levels, preventing crystallization and ensuring glossy, smooth candy surfaces. Their non-stick surfaces also facilitate easy candy removal without damage.

Airflow and Drying Efficiency

Cooling racks provide superior airflow around candy pieces due to their open grid design, promoting even drying and reducing moisture retention. Dehydrator trays, often solid or with limited perforations, may restrict airflow and extend drying times, impacting candy texture and quality.

- Open Grid Design - Cooling racks allow air to circulate freely on all sides, enhancing drying efficiency.

- Airflow Restriction - Dehydrator trays typically have smaller holes or solid surfaces that limit ventilation.

- Drying Time Impact - Improved airflow from cooling racks generally results in faster, more uniform candy drying.

Choosing a cooling rack optimizes airflow and drying speed, essential for achieving high-quality candied products.

Texture and Quality of Candied Goods

Which provides better texture and quality for candying: a cooling rack or a dehydrator tray? Cooling racks promote even air circulation around candied goods, resulting in a crispier texture and more uniform drying. Dehydrator trays offer controlled temperature settings that prevent overheating, preserving vibrant colors and a tender chew in the final product.

Ease of Use and Maintenance

Cooling racks offer a straightforward, no-fuss setup that allows air to circulate evenly around candy, simplifying the drying process. Their open design makes cleaning easy, requiring just a quick wash and dry to maintain hygiene.

Dehydrator trays, while slightly more complex to assemble, provide controlled temperature and humidity for precise candying results. Maintenance involves regular cleaning of trays and the appliance, which can be more time-consuming but ensures optimal performance.

Suitability for Different Types of Fruits and Sweets

Cooling racks offer better airflow and drainage, making them ideal for candying delicate fruits like berries and citrus slices that require even drying without moisture buildup. Dehydrator trays provide consistent temperature control and uniform drying, which suits thicker fruits such as apples, pears, and dense sweets like candied ginger. Choosing between a cooling rack and dehydrator tray depends on the fruit's moisture content and texture, with racks favoring lighter, juicier produce and trays benefiting thicker, denser items.

Related Important Terms

Micro-perforated Rack

A micro-perforated cooling rack provides superior airflow during the candying process, ensuring even drying and preventing sticky spots compared to solid trays. Unlike dehydrator trays, these racks reduce moisture buildup, enhancing texture and extending candy shelf life through efficient ventilation.

Precision Airflow Tray

A Precision Airflow Tray ensures even drying and consistent texture during candying by promoting optimal air circulation compared to a standard cooling rack, which can cause uneven moisture retention. Its design reduces drying time and improves candy quality by maintaining a controlled environment similar to a dehydrator tray but with enhanced airflow efficiency.

Nonstick Confection Grid

A cooling rack with a nonstick confection grid allows air circulation to prevent sticky buildup and promotes even drying during candying, while a dehydrator tray offers controlled temperature but may lack the essential nonstick surface that reduces candy adhesion. Choosing a cooling rack with a nonstick grid enhances efficiency by minimizing cleanup and maintaining the integrity of delicate candied pieces.

Stackable Candying Shelf

Stackable candying shelves offer superior airflow and space efficiency compared to both cooling racks and dehydrator trays, optimizing the drying process for candies. Their design allows uniform exposure to air, preventing sticking and ensuring consistent texture during candying.

Silicone Mesh Cooling Mat

Silicone mesh cooling mats provide superior airflow and non-stick surfaces compared to traditional cooling racks and dehydrator trays, ensuring even drying and preventing candy from sticking. Their heat-resistant and flexible design enhances candying efficiency by facilitating easy transfer and consistent cooling.

Low-heat Dehydration Plate

A low-heat dehydration plate offers precise temperature control essential for candying, preventing sugar crystallization and ensuring even drying, unlike a cooling rack that lacks temperature regulation. This specialized tray enhances moisture removal while maintaining the candy's texture and flavor integrity during the dehydration process.

Food-safe Drying Lattice

A food-safe cooling rack offers an open-grid design that promotes air circulation and even drying, making it ideal for candying small pieces or delicate treats. In contrast, a dehydrator tray with food-safe non-stick surfaces provides controlled temperature settings and moisture removal, ensuring consistent drying while preventing sticking or contamination during the candying process.

Rapid-Cool Sweet Tray

A Rapid-Cool Sweet Tray offers superior airflow and faster moisture removal compared to traditional cooling racks, optimizing the candying process by preventing stickiness and ensuring even drying. Its design enhances efficiency in temperature control and consistency, making it a preferred choice over dehydrator trays for rapid and uniform candy cooling.

Adjustable Temp Panel

A cooling rack offers passive air circulation but lacks precise temperature control, making it less ideal for consistent candying outcomes. Dehydrator trays with adjustable temp panels provide stable, customizable heat settings that optimize sugar crystallization and texture during the candying process.

Cooling Rack vs Dehydrator Tray for candying. Infographic

cookingdiff.com

cookingdiff.com