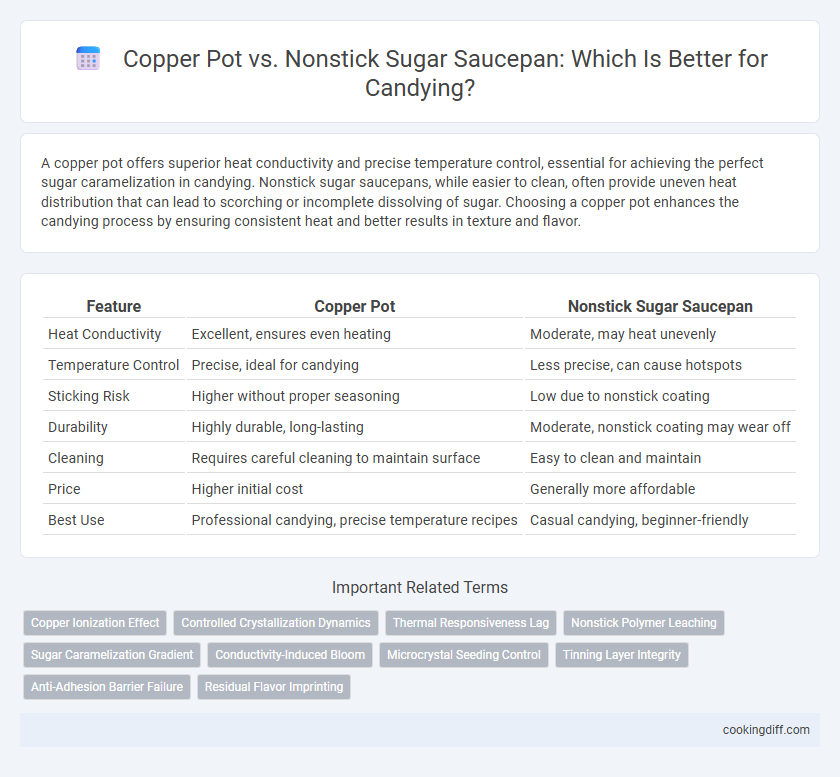

A copper pot offers superior heat conductivity and precise temperature control, essential for achieving the perfect sugar caramelization in candying. Nonstick sugar saucepans, while easier to clean, often provide uneven heat distribution that can lead to scorching or incomplete dissolving of sugar. Choosing a copper pot enhances the candying process by ensuring consistent heat and better results in texture and flavor.

Table of Comparison

| Feature | Copper Pot | Nonstick Sugar Saucepan |

|---|---|---|

| Heat Conductivity | Excellent, ensures even heating | Moderate, may heat unevenly |

| Temperature Control | Precise, ideal for candying | Less precise, can cause hotspots |

| Sticking Risk | Higher without proper seasoning | Low due to nonstick coating |

| Durability | Highly durable, long-lasting | Moderate, nonstick coating may wear off |

| Cleaning | Requires careful cleaning to maintain surface | Easy to clean and maintain |

| Price | Higher initial cost | Generally more affordable |

| Best Use | Professional candying, precise temperature recipes | Casual candying, beginner-friendly |

Introduction: Choosing the Right Pan for Candying

Copper pots offer superior heat conductivity and precise temperature control essential for candying sugar without burning. Nonstick sugar saucepans provide ease of cleanup and reduce the risk of sugar sticking, but may lack the even heat distribution copper ensures. Selecting between copper and nonstick pans depends on prioritizing temperature precision versus convenience in the candying process.

Copper Pots: Traditional Tool for Superior Candy Making

| Copper pots are preferred for candying due to their excellent heat conductivity, ensuring precise temperature control critical for sugar crystallization. Their ability to distribute heat evenly prevents hot spots, reducing the risk of burnt sugar compared to nonstick sugar saucepans. Traditional candy makers favor copper for its durability and consistent performance in achieving smooth, high-quality candy textures. |

Nonstick Sugar Saucepans: Modern Convenience Explained

Nonstick sugar saucepans provide a sleek, modern solution for candying by preventing sugar mixtures from sticking and burning. Their lightweight design and even heat distribution make them ideal for precise temperature control essential in candy making.

- Easy Cleanup - Nonstick surfaces simplify cleaning by preventing sugar residue from adhering to the pan.

- Consistent Heating - Modern nonstick coatings ensure uniform heat distribution to avoid hot spots during candy cooking.

- Durability - High-quality nonstick saucepans resist abrasion and maintain performance through repeated use in candying processes.

Heat Conductivity: Copper vs Nonstick Performance

Copper pots offer superior heat conductivity, distributing heat evenly and reducing hotspots during candying. This precise temperature control is crucial for achieving the perfect sugar caramelization without burning.

Nonstick sugar saucepans have lower thermal conductivity, leading to uneven heating and potential sugar crystallization. While easier to clean, nonstick pans may require more careful temperature monitoring to avoid scorching.

Temperature Precision and Control in Candying

Copper pots offer superior temperature precision due to their excellent heat conductivity, allowing for even and rapid temperature changes crucial for candying. Nonstick sugar saucepans, while convenient for cleanup, often provide less consistent heat distribution, posing risks of burning or uneven candy texture.

- Copper Pot Heat Conductivity - Copper rapidly responds to temperature changes, ensuring accurate control during the candying process.

- Nonstick Surface Benefits - Nonstick pans prevent sugar from sticking but may heat unevenly, affecting candy quality.

- Temperature Stability - Copper pots maintain a stable temperature, reducing the likelihood of hot spots that can cause crystallization.

Choosing a copper pot enhances temperature precision essential for perfect candying results.

Cleaning and Maintenance: Which Pan Is Easier?

Which pan is easier to clean and maintain for candying, a copper pot or a nonstick sugar saucepan? Copper pots require thorough drying and occasional polishing to prevent tarnishing, making maintenance more labor-intensive. Nonstick sugar saucepans offer effortless cleaning with simple washing and minimal residue, ideal for quick turnarounds in candying tasks.

Durability and Longevity: Invest in the Best

Copper pots offer exceptional durability and heat conduction, making them ideal for candying where precise temperature control is crucial. Their longevity surpasses nonstick sugar saucepans, as copper resists warping and maintains performance over years of use.

Nonstick sugar saucepans provide convenience with easy cleanup but often degrade faster, especially under high heat used in candying. Investing in a copper pot ensures consistent results and a durable tool that withstands frequent candy-making sessions.

Flavor and Texture: Does the Pan Material Matter?

Copper pots provide superior heat conductivity, allowing for precise temperature control essential in candying, which enhances the final flavor and texture of the candy. Nonstick sugar saucepans offer ease of use and cleaning but may not distribute heat as evenly, potentially leading to uneven cooking and subtle flavor differences. The choice of pan material can significantly influence the smoothness and clarity of the candy's texture, making copper a preferred option for professional candy makers.

Pros and Cons: Copper Pot vs Nonstick Saucepan

Copper pots provide superior heat conductivity and precise temperature control, essential for perfect candying results; however, they require careful maintenance to prevent tarnishing and reaction with acidic ingredients. Nonstick sugar saucepans offer easy cleanup and reduced risk of burning candy due to their nonstick surface but can have uneven heat distribution, affecting the candy's texture.

Copper pots excel in responsiveness to temperature changes, making them ideal for delicate sugar work like caramel and fudge. They are often more expensive and demand seasoning or polishing to maintain performance. Nonstick saucepans are more affordable and user-friendly for home cooks but may degrade under high heat, leading to a shorter lifespan compared to copper pots.

Related Important Terms

Copper Ionization Effect

Copper saucepans enhance candying by releasing trace amounts of copper ions, which catalyze sugar crystallization and promote even heat distribution, preventing grainy textures. Nonstick sugar saucepans lack this ionization effect, often resulting in less controlled crystallization and inconsistent candy textures.

Controlled Crystallization Dynamics

Copper pots offer superior thermal conductivity that ensures even heat distribution, minimizing hot spots and enabling precise control over crystallization dynamics during candying. Nonstick sugar saucepans, while convenient, often provide less consistent heat control, which can lead to uneven crystallization and affect the texture and quality of the final candy product.

Thermal Responsiveness Lag

Copper pots demonstrate superior thermal responsiveness compared to nonstick sugar saucepans, allowing precise temperature control essential for candying processes. The rapid heat conduction of copper minimizes thermal lag, preventing sugar crystallization and ensuring smooth, consistent candy texture.

Nonstick Polymer Leaching

Nonstick sugar saucepans risk polymer leaching when exposed to high candying temperatures, potentially contaminating the sugar mixture and altering flavor. Copper pots, while requiring more maintenance, offer superior heat conductivity without chemical leaching, making them a safer choice for precise candying processes.

Sugar Caramelization Gradient

Copper pots provide superior heat conductivity and precise temperature control, creating a more uniform sugar caramelization gradient essential for consistent candying results. Nonstick sugar saucepans often have less even heat distribution, which can lead to uneven caramelization and increased risk of scorching.

Conductivity-Induced Bloom

Copper pots excel in conductivity-induced bloom during candying, ensuring rapid, even heat distribution that minimizes crystal formation and produces a smooth, glossy finish; in contrast, nonstick sugar saucepans, while convenient, often result in uneven heating that can cause irregular crystallization and less desirable texture. The superior thermal conductivity of copper directly influences sugar bloom by maintaining consistent temperatures critical for precise caramelization and sugar syrup consistency.

Microcrystal Seeding Control

Copper pot candying excels in microcrystal seeding control due to its superior thermal conductivity, which ensures even heat distribution and prevents sugar crystallization. Nonstick sugar saucepans offer ease of cleanup but often fall short in maintaining consistent temperatures, increasing the risk of unwanted crystallization during the candying process.

Tinning Layer Integrity

Copper pots maintain superior heat conductivity and even temperature control, preserving the tinning layer integrity essential for acid-rich sugar candying processes. Nonstick sugar saucepans risk damaging or degrading the tinning layer under high heat, potentially affecting flavor and safety during candying.

Anti-Adhesion Barrier Failure

Copper pots provide superior heat conductivity and create an effective anti-adhesion barrier that minimizes the risk of sugar crystallization during candying, reducing the likelihood of barrier failure. In contrast, nonstick sugar saucepans, despite their convenience, often experience faster coating degradation and uneven heat distribution, increasing the chances of anti-adhesion barrier failure and resulting in caramel sticking.

Copper Pot vs Nonstick Sugar Saucepan for candying. Infographic

cookingdiff.com

cookingdiff.com