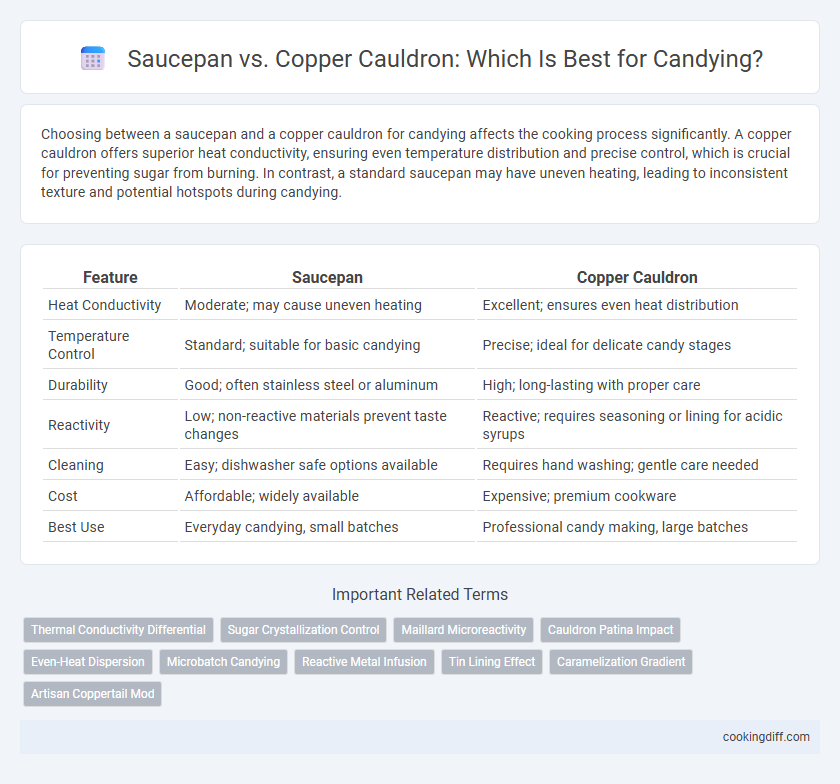

Choosing between a saucepan and a copper cauldron for candying affects the cooking process significantly. A copper cauldron offers superior heat conductivity, ensuring even temperature distribution and precise control, which is crucial for preventing sugar from burning. In contrast, a standard saucepan may have uneven heating, leading to inconsistent texture and potential hotspots during candying.

Table of Comparison

| Feature | Saucepan | Copper Cauldron |

|---|---|---|

| Heat Conductivity | Moderate; may cause uneven heating | Excellent; ensures even heat distribution |

| Temperature Control | Standard; suitable for basic candying | Precise; ideal for delicate candy stages |

| Durability | Good; often stainless steel or aluminum | High; long-lasting with proper care |

| Reactivity | Low; non-reactive materials prevent taste changes | Reactive; requires seasoning or lining for acidic syrups |

| Cleaning | Easy; dishwasher safe options available | Requires hand washing; gentle care needed |

| Cost | Affordable; widely available | Expensive; premium cookware |

| Best Use | Everyday candying, small batches | Professional candy making, large batches |

Introduction: The Art of Candying

Candying is a delicate culinary process that requires precise temperature control and even heat distribution. Choosing the right cookware, such as a saucepan or copper cauldron, significantly impacts the quality of the final product.

A saucepan offers convenience and uniform heating, making it suitable for beginners and everyday candying tasks. Copper cauldrons provide superior thermal conductivity and responsiveness, ideal for expert candy makers seeking perfection in texture and flavor.

Saucepan vs Copper Cauldron: A Quick Overview

Saucepans offer even heat distribution and are commonly made from stainless steel or aluminum, making them ideal for consistent candying results. Copper cauldrons heat up quickly and provide superior temperature control, which is crucial for delicate sugar work, but require regular polishing to maintain performance. Choosing between a saucepan and a copper cauldron hinges on balancing ease of use with precise thermal responsiveness during the candying process.

Heat Conductivity: Why Material Matters

When candying, a copper cauldron offers superior heat conductivity compared to a standard saucepan, allowing for more precise temperature control essential for sugar work. Copper's rapid and even heat distribution prevents hot spots, reducing the risk of burning or crystallizing sugar mixtures.

Copper cauldrons respond quickly to temperature changes, making them ideal for delicate candying processes that require exact heat adjustments. In contrast, most saucepans, typically made of stainless steel or aluminum, have slower heat response times which can lead to uneven cooking. This disparity in thermal conductivity impacts the texture and quality of the final candy product.

Temperature Control in Candying

Precise temperature control is essential in candying to prevent crystallization and achieve the perfect texture. Copper cauldrons offer superior heat conductivity compared to standard saucepans, allowing for more even and responsive temperature adjustments.

- Copper Cauldron Enhances Heat Distribution - Copper's excellent thermal conductivity ensures uniform heat, reducing hot spots during candying.

- Saucepan Heat Retention - Traditional saucepans often retain heat longer, requiring careful monitoring to avoid overheating.

- Temperature Precision Control - Copper cauldrons respond quickly to heat changes, providing more accurate temperature regulation critical for candy consistency.

Evenness of Cooking and Sugar Crystallization

Copper cauldrons provide superior heat conductivity, ensuring evenness of cooking essential for candying, which prevents hot spots that can cause uneven sugar crystallization. Saucepans made from stainless steel often have less consistent heat distribution, increasing the risk of sugar crystals forming prematurely. Maintaining precise temperature control with a copper cauldron results in smoother texture and higher quality candy.

Traditional Methods: The Role of the Copper Cauldron

Why is a copper cauldron preferred over a saucepan for candying in traditional methods? Copper cauldrons provide superior heat conductivity, ensuring even temperature control essential for delicate candying processes. Their ability to maintain consistent heat prevents sugar crystallization better than standard saucepans, preserving the perfect texture and flavor of confections.

Modern Convenience: Advantages of the Saucepan

Saucepans provide consistent heat control essential for precise candying processes, making them a preferred tool in modern kitchens. Their compatibility with induction and other contemporary stovetops offers convenience that traditional copper cauldrons lack.

- Even Heat Distribution - Saucepans often feature layered bases that ensure uniform heat, reducing the risk of burning sugar.

- Ease of Cleaning - Non-reactive surfaces in modern saucepans simplify post-cooking cleanup compared to copper's tendency to tarnish.

- Lightweight and Maneuverable - Saucepan designs are ergonomic, allowing greater control when stirring and pouring hot candy mixtures.

Saucepans combine traditional candying techniques with practical features that enhance efficiency and safety in today's culinary settings.

Maintenance and Longevity

Choosing between a saucepan and a copper cauldron for candying impacts maintenance routines and product longevity significantly. Copper cauldrons require more diligent upkeep to prevent tarnishing, yet they can last decades if properly maintained, while saucepans offer simpler cleaning but may wear out faster under high-heat candying processes.

- Copper Cauldron Durability - Copper cauldrons are highly durable and resistant to corrosion when regularly polished and dried after use.

- Maintenance Complexity - Saucepan maintenance is generally easier due to their stainless steel or non-stick surfaces requiring minimal care.

- Longevity Considerations - Properly maintained copper cauldrons often outlast conventional saucepans by a significant margin in candy-making tasks.

Safety Considerations When Candying

| Safety Considerations When Candying: Saucepan vs Copper Cauldron |

| Saucepans made from stainless steel or heavy-duty aluminum offer even heat distribution and are generally safer for candying, reducing risks of hot spots that can cause burning or boiling over. Copper cauldrons provide superior thermal conductivity, but they require careful monitoring and proper seasoning to prevent reactions with acidic ingredients and potential metal leaching. Choosing cookware with sturdy handles and a stable base minimizes the risk of spills and burns during the high-temperature candying process. |

Related Important Terms

Thermal Conductivity Differential

Copper cauldrons have superior thermal conductivity compared to saucepans, enabling more precise and even heat distribution essential for candying processes. This efficient heat transfer reduces the risk of hot spots and caramelization inconsistencies, resulting in smoother, better-textured candy outcomes.

Sugar Crystallization Control

Copper cauldrons offer superior heat conductivity essential for even temperature distribution, minimizing sugar crystallization during candying. Saucepans, often made from stainless steel or aluminum, heat less uniformly, increasing the risk of uneven sugar crystallization and grainy textures in confections.

Maillard Microreactivity

Copper cauldrons facilitate superior Maillard microreactivity during candying due to their excellent heat conductivity and precise temperature control, which minimizes hot spots and promotes even browning. Saucepans, typically made from stainless steel or aluminum, often exhibit uneven heating that can hinder Maillard reactions and result in inconsistent candy texture and flavor development.

Cauldron Patina Impact

A copper cauldron develops a natural patina that enhances heat conductivity and imparts subtle flavor complexity important for candying sugar mixtures. This patina promotes even caramelization and prevents hot spots that often occur with standard saucepans, leading to superior texture and color in the final candied product.

Even-Heat Dispersion

Copper cauldrons provide superior even-heat dispersion compared to saucepans, ensuring consistent temperature control during candying and preventing hot spots that can cause burning. This precise heat distribution enhances the texture and quality of the candy by promoting uniform cooking and caramelization.

Microbatch Candying

For microbatch candying, copper cauldrons offer superior heat conductivity and precise temperature control, essential for achieving consistent texture and preventing crystal formation during sugar cooking. Saucepans, while more common and affordable, may cause uneven heating, making them less ideal for delicate small-batch candying processes.

Reactive Metal Infusion

Using a copper cauldron for candying offers superior heat conductivity but carries a risk of reactive metal infusion, which can alter the flavor and color of delicate sugar mixtures. Saucepans made from non-reactive materials like stainless steel prevent unwanted metal interaction, ensuring pure taste and consistent results during candying processes.

Tin Lining Effect

Copper cauldrons with tin lining provide excellent heat conductivity and even temperature distribution, crucial for precise candying processes that require controlled sugar crystallization. While saucepans may vary in material, the tin lining in copper cauldrons prevents copper from reacting with acidic sugar mixtures, preserving flavor and ensuring safety during candying.

Caramelization Gradient

Copper cauldrons provide superior heat conductivity allowing for a more even caramelization gradient during candying, which helps prevent hotspots and burning. Saucepans, typically made of stainless steel or aluminum, often create uneven heat distribution that can cause inconsistent caramelization and affect the texture and flavor of the candy.

Saucepan vs Copper Cauldron for Candying. Infographic

cookingdiff.com

cookingdiff.com