Candying preserves fruit by soaking it in sugar syrup, which infuses sweetness and creates a chewy texture, while vacuum glazing involves coating fruit with a thin layer of liquid sugar under vacuum to seal in moisture and enhance shine. Candying is ideal for long-term preservation and intense sweetness, whereas vacuum glazing maintains the fruit's natural flavor and freshness with a glossy finish. Both techniques extend shelf life but differ in texture, appearance, and sugar concentration.

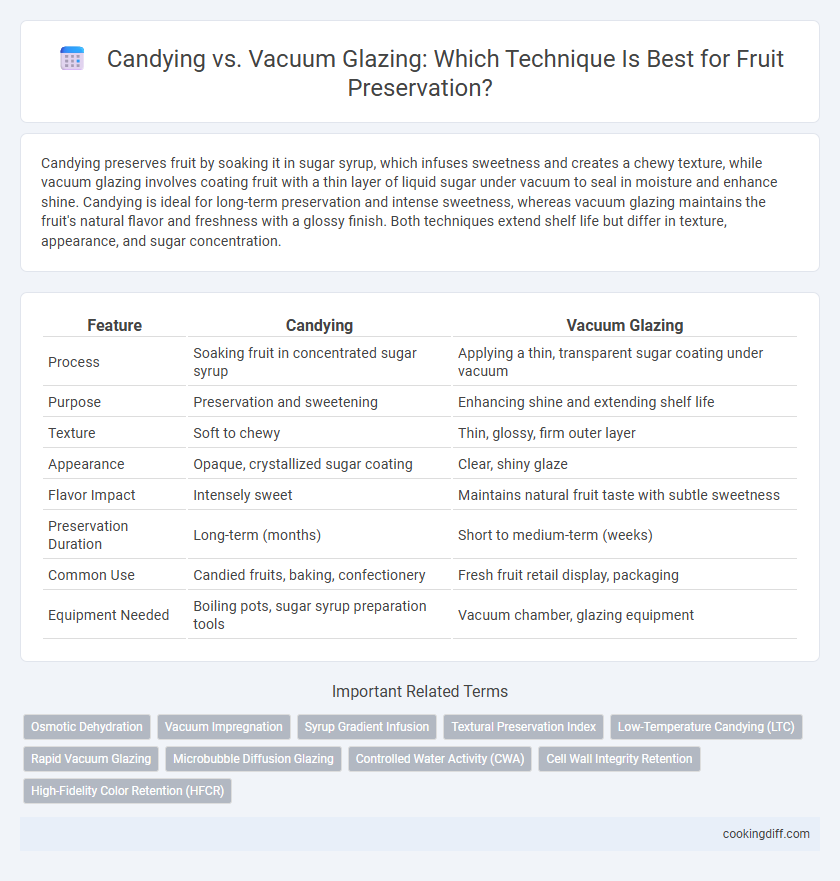

Table of Comparison

| Feature | Candying | Vacuum Glazing |

|---|---|---|

| Process | Soaking fruit in concentrated sugar syrup | Applying a thin, transparent sugar coating under vacuum |

| Purpose | Preservation and sweetening | Enhancing shine and extending shelf life |

| Texture | Soft to chewy | Thin, glossy, firm outer layer |

| Appearance | Opaque, crystallized sugar coating | Clear, shiny glaze |

| Flavor Impact | Intensely sweet | Maintains natural fruit taste with subtle sweetness |

| Preservation Duration | Long-term (months) | Short to medium-term (weeks) |

| Common Use | Candied fruits, baking, confectionery | Fresh fruit retail display, packaging |

| Equipment Needed | Boiling pots, sugar syrup preparation tools | Vacuum chamber, glazing equipment |

Introduction to Candying and Vacuum Glazing

Candying is a preservation technique that involves soaking fruit in sugar syrup to enhance sweetness and extend shelf life. This method allows the fruit to maintain its texture while developing a glossy, sugary coating.

Vacuum glazing, on the other hand, uses a thin layer of fat applied under vacuum conditions to seal moisture and preserve fruit freshness. It provides a protective barrier that helps maintain the fruit's natural color and flavor without adding sweetness.

Understanding the Candying Process

What distinguishes the candying process from vacuum glazing when preserving fruit? Candying involves slowly infusing fruit with sugar syrup to replace water content, enhancing flavor and shelf life through osmotic dehydration. Unlike vacuum glazing, which coats fruit to protect and seal freshness, candying transforms the fruit's texture and sweetness internally through sugar absorption.

What Is Vacuum Glazing?

Vacuum glazing is a preservation method that creates a tight, airtight seal around fruit by removing air before sealing, which inhibits oxidation and moisture loss. Unlike candying, which involves soaking fruit in sugar syrup to achieve preservation and sweetness, vacuum glazing focuses on maintaining the fruit's natural texture and flavor without added sugars. This technique extends shelf life while preserving freshness and nutritional quality through controlled atmosphere packaging.

Key Differences in Technique

Candying involves slowly infusing fruit with sugar syrup over an extended period, preserving texture and sweetness. Vacuum glazing uses low pressure to quickly infuse a sugar coating, creating a thin, glossy layer without long soaking.

- Process Duration - Candying requires days or weeks of gradual sugar absorption, while vacuum glazing completes within hours.

- Technique - Candying soaks fruit in heated sugar solutions, whereas vacuum glazing applies sugar under vacuum conditions for rapid coating.

- Texture Outcome - Candying results in firm, translucent fruit, whereas vacuum glazing produces a crisp, shiny sugar surface.

Taste and Texture Comparison

Candying fruit preserves its natural sweetness while creating a chewy, slightly sticky texture that enhances flavor retention. Vacuum glazing, on the other hand, seals fruit with a thin, smooth layer that maintains juiciness and results in a more delicate, tender bite. Taste-wise, candied fruit tends to have a richer, caramelized profile, whereas vacuum-glazed fruit offers a fresher, cleaner taste experience.

Visual Appeal: Presentation Matters

| Visual Appeal: Candying vs Vacuum Glazing |

| Candied fruits showcase a vibrant, crystalline sugar coating that enhances their natural colors and texture, making them visually striking for desserts and garnishing. Vacuum glazing creates a smooth, glossy, and translucent finish that preserves the fruit's fresh appearance while providing a sleek presentation. Both methods emphasize presentation, with candying offering a textured sparkle and vacuum glazing delivering a polished, elegant look ideal for culinary displays. |

Shelf Life and Preservation

Candied fruits have an extended shelf life due to high sugar concentration that inhibits microbial growth, making them stable for months. Vacuum glazing, while effective in sealing moisture and oxygen, typically offers a shorter preservation period compared to candying.

- Candying extends shelf life - Sugar acts as a natural preservative by reducing water activity, preventing spoilage and mold.

- Vacuum glazing seals freshness - The vacuum layer reduces oxygen exposure, slowing oxidation and dehydration but not eliminating microbial risks.

- Candied fruits resist spoilage longer - Their dense sugar coating maintains texture and flavor over extended storage periods.

Candying remains the preferred method for long-term fruit preservation due to superior shelf stability compared to vacuum glazing.

Equipment and Skill Requirements

Candiying fruit requires basic equipment such as pots, thermometers, and skill in controlling syrup concentration, allowing for delicate texture preservation. Vacuum glazing demands specialized vacuum chambers and advanced knowledge to ensure uniform coating without structural damage.

- Candiying Equipment - Utilizes standard kitchen tools like heavy pots and candy thermometers for syrup preparation.

- Vacuum Glazing Equipment - Requires complex vacuum chambers and precision sealing machinery to apply coatings.

- Skill Requirements - Candying demands experience in syrup boiling and timing, while vacuum glazing needs technical training in vacuum pressure and temperature control.

Applications in Modern and Traditional Cuisine

Candying preserves fruit by immersing it in sugar syrup, enhancing flavor and texture, while vacuum glazing involves applying a thin sugar coating under reduced pressure to seal freshness. Both methods are prominent in traditional confectionery, yet candying maintains a classic appeal in artisanal desserts and fruitcakes.

Modern cuisine employs candying primarily for decorative garnishes and gourmet desserts, leveraging its rich sweetness and chewy texture. Vacuum glazing finds specialized use in high-end patisserie, providing a glossy finish and extended shelf life without altering fruit moisture significantly. The choice between these techniques depends on desired texture, appearance, and preservation goals in culinary applications.

Related Important Terms

Osmotic Dehydration

Osmotic dehydration in candying involves immersing fruit in a concentrated sugar solution to remove water and infuse sweetness, enhancing texture and preservation naturally. Vacuum glazing, by contrast, seals the fruit surface to prevent moisture loss without significant osmotic exchange, resulting in different preservation and sweetness profiles.

Vacuum Impregnation

Vacuum impregnation enhances fruit candying by infusing syrup deep into the cellular structure under reduced pressure, resulting in uniform sweetness and improved texture retention. This technique outperforms traditional vacuum glazing by enabling better syrup absorption and extending shelf life without surface stickiness.

Syrup Gradient Infusion

Candying relies on a gradual syrup gradient infusion to preserve fruit texture and sweetness by slowly replacing moisture with sugar, ensuring even penetration and enhanced flavor. Vacuum glazing, while sealing the fruit with a sugar coating, does not achieve the same depth of syrup infusion, often resulting in less uniform sweetness and texture.

Textural Preservation Index

Candying preserves fruit texture by slowly infusing sugar syrup, maintaining a high Textural Preservation Index (TPI) of around 85%, whereas Vacuum Glazing achieves a TPI near 70% by rapidly coating fruit in a protective syrup layer that can soften the texture. The slower process of candying minimizes cell wall breakdown, retaining firmness, while vacuum glazing prioritizes surface preservation at the expense of internal texture integrity.

Low-Temperature Candying (LTC)

Low-Temperature Candying (LTC) preserves fruit texture and enhances flavor by gently infusing sugar at temperatures below 70degC, minimizing nutrient loss compared to traditional candying methods. Unlike Vacuum Glazing, LTC maintains the fruit's natural moisture balance and results in a more tender, flavor-intense product ideal for delicate fruits such as berries and citrus segments.

Rapid Vacuum Glazing

Rapid vacuum glazing preserves fruit by quickly removing air to enhance flavor retention, texture, and shelf life, unlike traditional candying which relies on sugar infusion over time. This method significantly reduces oxidation and dehydration, maintaining the fruit's natural color and nutritional value more effectively.

Microbubble Diffusion Glazing

Microbubble Diffusion Glazing enhances fruit candying by using microscopic bubbles to evenly distribute sugar solutions, resulting in improved texture and flavor penetration compared to traditional vacuum glazing methods. This technique minimizes vacuum-induced damage and promotes superior sugar absorption, extending shelf life while preserving fruit integrity.

Controlled Water Activity (CWA)

Candying preserves fruit by reducing water content to achieve controlled water activity (CWA), inhibiting microbial growth and enzymatic reactions while maintaining texture and flavor. Vacuum glazing offers similar microbial stability by applying a protective sugar coating under reduced pressure, enhancing CWA control through uniform sugar penetration and moisture reduction.

Cell Wall Integrity Retention

Candying preserves fruit by osmotically replacing water with sugar, which helps maintain cell wall integrity and prevents structural degradation during storage. Vacuum glazing, while providing a protective barrier, may not penetrate as effectively to stabilize cell walls, potentially resulting in less retention of fruit texture compared to candying.

Candying vs Vacuum Glazing for fruit. Infographic

cookingdiff.com

cookingdiff.com