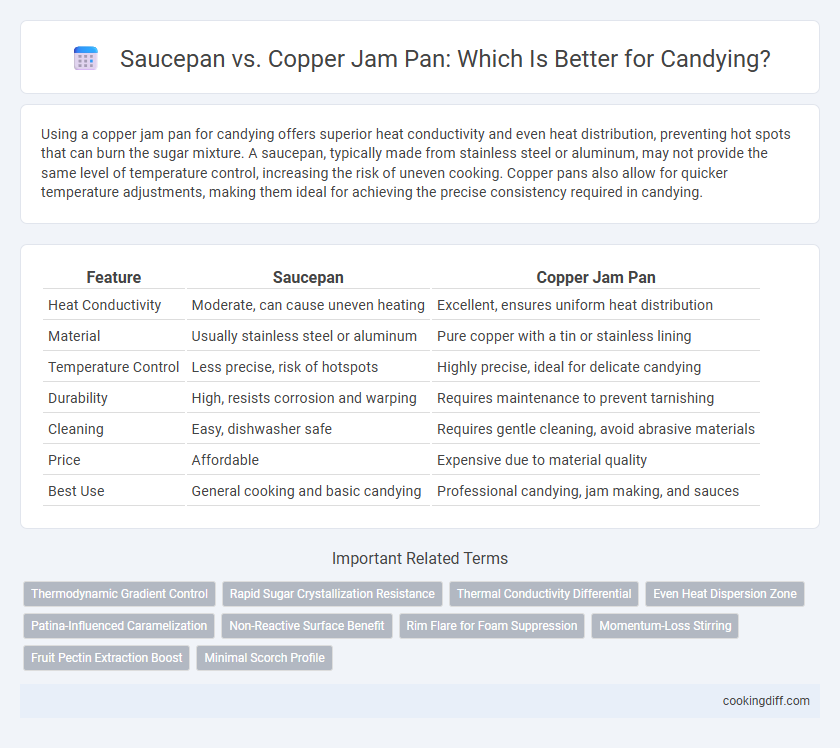

Using a copper jam pan for candying offers superior heat conductivity and even heat distribution, preventing hot spots that can burn the sugar mixture. A saucepan, typically made from stainless steel or aluminum, may not provide the same level of temperature control, increasing the risk of uneven cooking. Copper pans also allow for quicker temperature adjustments, making them ideal for achieving the precise consistency required in candying.

Table of Comparison

| Feature | Saucepan | Copper Jam Pan |

|---|---|---|

| Heat Conductivity | Moderate, can cause uneven heating | Excellent, ensures uniform heat distribution |

| Material | Usually stainless steel or aluminum | Pure copper with a tin or stainless lining |

| Temperature Control | Less precise, risk of hotspots | Highly precise, ideal for delicate candying |

| Durability | High, resists corrosion and warping | Requires maintenance to prevent tarnishing |

| Cleaning | Easy, dishwasher safe | Requires gentle cleaning, avoid abrasive materials |

| Price | Affordable | Expensive due to material quality |

| Best Use | General cooking and basic candying | Professional candying, jam making, and sauces |

Introduction to Candying: Choosing the Right Pan

Choosing the right pan is crucial for successful candying, as the pan's material affects heat distribution and control. Copper jam pans provide excellent thermal conductivity, allowing even heating which prevents burning or uneven candy texture.

Saucepans, typically made from stainless steel or aluminum, may not offer the same precise temperature control as copper but are more affordable and widely available. For candying, copper jam pans are preferred by professionals for their superior heat responsiveness and consistent results.

What is a Saucepan? Features & Uses in Candying

A saucepan is a versatile cookware piece with deep sides and a flat bottom, ideal for cooking liquids and sauces evenly. In candying, its ability to maintain consistent heat makes it suitable for simmering syrups and melting sugar without burning.

- Material diversity - Saucepans come in stainless steel, aluminum, and non-stick varieties, affecting heat distribution and ease of cleaning.

- Heat control - The thick bottom of a good saucepan helps prevent hotspots, crucial for precise sugar temperature control in candying.

- Size and capacity - Available in multiple sizes, saucepans accommodate small or larger batches of candy syrup efficiently.

Exploring the Copper Jam Pan: Unique Qualities

| The copper jam pan offers exceptional heat conductivity, ensuring even cooking and reducing the risk of scorching during the candying process. Its ability to rapidly adjust temperature allows for precise control, critical in achieving the perfect consistency for candied fruits. This unique quality makes copper jam pans a preferred choice for professional candy makers compared to traditional saucepans. |

Heat Conductivity: Saucepan vs Copper Jam Pan

Copper jam pans offer superior heat conductivity compared to regular saucepans, ensuring even heat distribution critical for candying. Saucepans may develop hot spots, which can lead to uneven cooking and caramelization.

- Heat Conductivity Advantage - Copper's thermal conductivity is approximately 401 W/m*K, far exceeding stainless steel saucepans, enabling precise temperature control.

- Even Heat Distribution - Copper jam pans minimize hot spots, preventing burning and ensuring consistent candy texture during cooking.

- Temperature Responsiveness - Copper responds rapidly to temperature changes, allowing better management of delicate sugar stages in candying.

Sugar Crystallization Control in Candying

Which is more effective for controlling sugar crystallization in candying, a saucepan or a copper jam pan? Copper jam pans offer superior heat conductivity, ensuring even temperature distribution that minimizes hot spots and reduces the risk of premature sugar crystallization. Saucepans made from stainless steel or aluminum may cause uneven heating, increasing the likelihood of sugar crystals forming during the candying process.

Even Heating and Temperature Stability

Copper jam pans provide superior even heating and excellent temperature stability, essential for precise candying processes that require consistent heat to prevent burning or crystallization. Saucepans, typically made from stainless steel or aluminum, may have uneven heat distribution, leading to hot spots that can disrupt the candying process. The thermal conductivity of copper ensures quick, uniform heat adjustments, making it the preferred choice for delicate sugar work and achieving optimal candy texture.

Ease of Use and Handling

When candying, saucepans offer easier handling and are generally more user-friendly for beginners due to their lightweight design. Copper jam pans, though heavier, provide superior heat conductivity for precise temperature control but can be challenging to maneuver.

- Saucepan lightness - Easier to lift and stir, reducing hand fatigue during candying.

- Copper jam pan heat control - Offers even, rapid heat distribution to prevent hot spots.

- Saucepan versatility - Ideal for various kitchen tasks beyond candying.

Choosing between them depends on balancing ease of handling with cooking precision.

Cleaning and Maintenance Requirements

Saucepans are generally easier to clean due to their non-reactive surfaces and smooth coatings, which prevent sticky residue from adhering during candying. Copper jam pans require careful cleaning to maintain their copper finish and prevent tarnishing, often needing specialized polishes and gentle handling.

While saucepans typically withstand dishwasher use and abrasive scrubbing, copper jam pans demand hand washing with mild detergents and immediate drying to avoid water spots and corrosion. The natural patina on copper enhances flavor development but increases maintenance time. Regular polishing is essential to preserve copper's heat conductivity and aesthetic appeal over time.

Cost Comparison and Long-term Value

Copper jam pans generally come with a higher initial cost compared to standard saucepans but offer superior heat conductivity, leading to more precise candying results. While saucepans are more affordable and widely accessible, they may require longer cooking times and can produce uneven heating, potentially impacting the quality of the candying process. Investing in a copper jam pan often results in long-term savings due to enhanced durability and improved efficiency, making it a preferred choice for serious candy makers.

Related Important Terms

Thermodynamic Gradient Control

Copper jam pans provide superior thermodynamic gradient control compared to saucepans due to their excellent thermal conductivity, allowing for even heat distribution and precise temperature regulation during candying. This enhanced control minimizes hotspots and reduces the risk of burning, ensuring consistent texture and color in the final candied product.

Rapid Sugar Crystallization Resistance

Copper jam pans offer superior rapid sugar crystallization resistance due to their excellent heat conductivity and even heat distribution, preventing hot spots that cause premature crystallization. Saucepans, typically made from stainless steel or aluminum, tend to have uneven heating, increasing the risk of sugar crystallizing too quickly during the candying process.

Thermal Conductivity Differential

Copper jam pans offer superior thermal conductivity, heating evenly and reducing hotspots during candying, which minimizes the risk of burning sugar mixtures. In contrast, saucepans with lower thermal conductivity can result in uneven cooking, affecting the texture and consistency of the candy.

Even Heat Dispersion Zone

Copper jam pans provide superior even heat dispersion due to copper's high thermal conductivity, ensuring consistent temperature control and preventing hot spots during candying. Saucepans, typically made from stainless steel or aluminum, may have uneven heat zones that increase the risk of burning or uneven cooking in delicate candy-making processes.

Patina-Influenced Caramelization

Copper jam pans develop a natural patina that enhances heat conductivity and promotes even caramelization, resulting in richer, more complex flavors during candying. In contrast, saucepans may lack this patina-driven thermal responsiveness, often leading to uneven caramelization and inconsistent texture in candied fruits or syrups.

Non-Reactive Surface Benefit

A copper jam pan offers a non-reactive surface that prevents unwanted chemical reactions, preserving the pure flavor of fruits during candying. Unlike some saucepans that may react with acidic ingredients, copper pans ensure consistent heat distribution and maintain the candy's color and taste integrity.

Rim Flare for Foam Suppression

Copper jam pans with a pronounced rim flare effectively suppress foam during candying by promoting better vapor release and reducing foam buildup compared to standard saucepans. The wider, flared rim design of copper pans enhances heat distribution and minimizes boil-over, making them ideal for precise sugar work.

Momentum-Loss Stirring

Copper jam pans offer superior heat conductivity and even heat distribution, reducing resistance during momentum-loss stirring for candying, whereas saucepans may create hotspots causing inconsistent stirring and potential crystallization. The low thermal inertia of copper allows for precise temperature control, preserving syrup consistency and optimizing crystallization prevention during candying processes.

Fruit Pectin Extraction Boost

Copper jam pans enhance fruit pectin extraction during candying by providing superior heat conductivity and even temperature distribution, which prevents scorching and preserves pectin integrity. Saucepans, typically made from stainless steel, offer less consistent heat control, potentially reducing the efficiency of pectin release and resulting in a thicker, less consistent preserve.

Saucepan vs Copper Jam Pan for candying. Infographic

cookingdiff.com

cookingdiff.com