Candying ginger involves simmering slices in sugar syrup to preserve and enhance natural sweetness through slow absorption. Vacuum-infused candying accelerates this process by using reduced pressure to infuse sugar deeply and evenly, resulting in a more consistent texture and intensified flavor. Compared to traditional candying, vacuum infusion reduces processing time and improves moisture retention while maintaining the ginger's aromatic qualities.

Table of Comparison

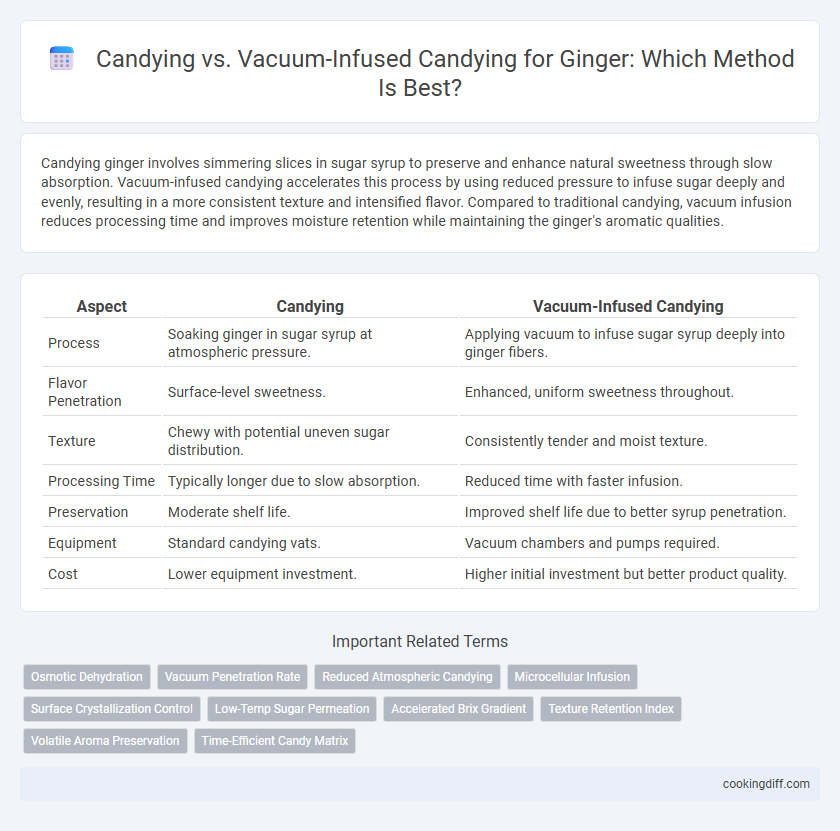

| Aspect | Candying | Vacuum-Infused Candying |

|---|---|---|

| Process | Soaking ginger in sugar syrup at atmospheric pressure. | Applying vacuum to infuse sugar syrup deeply into ginger fibers. |

| Flavor Penetration | Surface-level sweetness. | Enhanced, uniform sweetness throughout. |

| Texture | Chewy with potential uneven sugar distribution. | Consistently tender and moist texture. |

| Processing Time | Typically longer due to slow absorption. | Reduced time with faster infusion. |

| Preservation | Moderate shelf life. | Improved shelf life due to better syrup penetration. |

| Equipment | Standard candying vats. | Vacuum chambers and pumps required. |

| Cost | Lower equipment investment. | Higher initial investment but better product quality. |

Introduction to Candying and Vacuum-Infused Candying

Candying is a traditional preservation method that involves simmering ginger in sugar syrup until it becomes tender and infused with sweetness. This process enhances the ginger's flavor while extending its shelf life by coating it in crystallized sugar.

Vacuum-infused candying is a modern technique that uses reduced pressure to accelerate the absorption of sugar syrup into the ginger. This method preserves more of the ginger's natural aroma and results in a more evenly sweetened product. By reducing processing time and temperature, vacuum-infused candying helps retain the ginger's texture and nutritional properties.

What Is Traditional Candying?

Traditional candying involves simmering ginger in a sugar syrup until it becomes translucent and infused with sweetness. This time-tested method relies on heat and prolonged soaking to preserve and sweeten the ginger naturally.

- Sugar Infusion - Ginger pieces absorb sugar gradually through slow cooking in high-concentration syrup.

- Textural Transformation - The process softens ginger while maintaining slight firmness for a chewy bite.

- Extended Time Requirement - Candying can take several hours to achieve optimal syrup penetration and flavor balance.

How Vacuum-Infused Candying Works

Vacuum-infused candying for ginger involves placing the ginger in a sugar syrup chamber where reduced pressure allows the syrup to penetrate deeper into the ginger fibers. This process enhances flavor absorption and shortens the candying time compared to traditional methods.

The vacuum environment removes air pockets inside the ginger, allowing the syrup to infuse more evenly and thoroughly. This technique results in a moister, more intensely sweetened ginger candy with improved texture and shelf life.

Key Differences Between Traditional and Vacuum-Infused Methods

| Key Aspect | Traditional Candying | Vacuum-Infused Candying |

|---|---|---|

| Process | Soaking ginger in sugar syrup over extended periods to allow natural absorption. | Applying vacuum pressure to infuse sugar syrup rapidly into ginger, reducing infusion time. |

| Texture and Flavor | Produces a softer texture with gradual flavor development through slow syrup penetration. | Results in a firmer texture and more intense ginger flavor due to deeper and uniform infusion. |

| Efficiency | Requires several days for complete candying, impacting production speed. | Completes candying within hours, significantly improving production efficiency and consistency. |

| Moisture Retention | Higher moisture content can cause quicker spoilage without preservatives. | Enhanced moisture control extends shelf life and improves product stability. |

Ingredients Needed for Both Methods

Both candying and vacuum-infused candying of ginger require fresh ginger root, sugar, and water as primary ingredients. The traditional candying process often uses a simple syrup made from equal parts sugar and water, while vacuum-infused candying may incorporate a more concentrated syrup to enhance flavor absorption.

The vacuum-infused method also benefits from the absence of air, which allows sugar molecules to penetrate the ginger more deeply and evenly. This technique can reduce the quantity of sugar needed compared to traditional candying, resulting in a potentially less sweet but intensely flavored product.

Step-by-Step Traditional Candying Process for Ginger

The traditional candying process for ginger involves peeling and slicing fresh ginger before boiling it in a sugar syrup until the slices become translucent and infused with sweetness. After boiling, the ginger slices are slowly dried to develop a chewy texture while preserving their spicy flavor. This step-by-step method contrasts with vacuum-infused candying, which accelerates sugar absorption but lacks the gradual texture development found in traditional candying.

Vacuum-Infused Candying Process Explained

The vacuum-infused candying process infuses ginger with sugar syrup under reduced pressure, enhancing flavor penetration and texture consistency. This method accelerates the candying cycle compared to traditional candying by removing air pockets for better syrup absorption.

- Vacuum Pressure Application - Applying vacuum lowers air pressure, allowing syrup to permeate ginger tissues more effectively.

- Enhanced Flavor Infusion - The vacuum environment intensifies sugar and spice absorption, creating richer taste profiles.

- Shortened Processing Time - Reduced pressure speeds up moisture removal and sugar crystallization, making the process faster.

The vacuum-infused candying technique produces ginger with improved sweetness, tenderness, and shelf life compared to traditional methods.

Texture and Flavor Comparison: Traditional vs Vacuum-Infused Ginger

Candying ginger through traditional methods results in a chewy texture with a robust, slightly caramelized flavor profile, while vacuum-infused candying produces a more tender bite and intensified ginger aroma due to enhanced infusion of syrup. The vacuum process preserves more natural zing, creating a brighter and fresher taste.

- Texture Contrast - Traditional candying yields a firmer, chewier texture compared to the softer, more uniform texture from vacuum-infused candying.

- Flavor Intensity - Vacuum-infused ginger candy exhibits a stronger, more concentrated ginger flavor, whereas traditional candying offers deeper caramel notes.

- Retention of Natural Notes - Vacuum-infused methods better preserve the inherent spicy and fresh notes of ginger, enhancing overall flavor complexity.

Shelf Life and Storage Considerations

Candying ginger through traditional methods enhances shelf life by reducing moisture content, but vacuum-infused candying further extends preservation by infusing syrup under reduced pressure, which inhibits microbial growth more effectively. Vacuum-infused ginger candies maintain texture and flavor longer during storage, requiring less refrigeration compared to conventionally candied ginger. Proper airtight packaging is essential for both methods to prevent moisture absorption and prolong shelf stability.

Related Important Terms

Osmotic Dehydration

Candying ginger through osmotic dehydration involves immersing the ginger slices in a concentrated sugar syrup, which gradually draws out water and replaces it with sugar, preserving flavor and texture. Vacuum-infused candying accelerates this osmotic process by reducing pressure, enhancing syrup penetration and dehydration efficiency while maintaining the ginger's structural integrity.

Vacuum Penetration Rate

Vacuum-infused candying enhances the vacuum penetration rate by creating a low-pressure environment that accelerates syrup absorption into ginger, resulting in a more uniform and deeply flavored product compared to traditional candying methods. This increased vacuum penetration rate reduces processing time while improving the texture and taste consistency of candied ginger.

Reduced Atmospheric Candying

Reduced atmospheric candying of ginger enhances flavor infusion and texture retention by lowering pressure to accelerate sugar absorption, unlike traditional candying methods that rely on atmospheric pressure. This vacuum-infused candying technique minimizes processing time and preserves ginger's natural aroma and color, offering a superior quality product.

Microcellular Infusion

Microcellular infusion in vacuum-infused candying significantly enhances the absorption of sugar syrup into ginger's porous structure, resulting in a more uniform sweetness and improved texture compared to traditional candying. This process exploits pressure variations to expand microcells within the ginger, allowing deeper penetration of syrup and preserving the ginger's natural flavor and moisture.

Surface Crystallization Control

Candying ginger through traditional methods often results in uneven surface crystallization, leading to inconsistent texture and clumping. Vacuum-infused candying enhances surface crystallization control by evenly distributing sugar crystals under reduced pressure, producing a smoother, more uniform coating and improved shelf stability.

Low-Temp Sugar Permeation

Candying ginger using low-temperature sugar permeation preserves the root's natural texture and enhances flavor absorption without compromising its structural integrity. Vacuum-infused candying accelerates sugar infusion by reducing pressure, yet low-temp permeation ensures a gentler process that maintains ginger's aromatic compounds and prevents crystallization issues.

Accelerated Brix Gradient

Candying ginger using vacuum-infused candying accelerates the Brix gradient by enhancing sugar penetration through reduced pressure environments, significantly speeding up the syrup absorption process compared to traditional candying methods. This accelerated Brix gradient results in a more uniform sweetness distribution and improved texture, optimizing flavor infusion in a shorter time frame.

Texture Retention Index

Candying ginger using traditional methods typically results in a lower Texture Retention Index due to prolonged exposure to sugar syrup, causing softness and reduced firmness. Vacuum-infused candying enhances the Texture Retention Index by using reduced pressure to rapidly infuse sugar while preserving the ginger's original crispness and structural integrity.

Volatile Aroma Preservation

Candying ginger through traditional methods often results in the loss of delicate volatile aromas due to prolonged exposure to heat and sugar saturation, whereas vacuum-infused candying preserves these essential oils by minimizing oxidation and reducing heat exposure. This advanced technique enhances the flavor profile and aroma intensity, maintaining the ginger's natural aromatic compounds more effectively.

Candying vs Vacuum-infused Candying for ginger. Infographic

cookingdiff.com

cookingdiff.com