A candy thermometer provides precise temperature readings by direct contact with the hot sugar mixture, ensuring accurate control during candying for perfect texture and consistency. Infrared thermometers measure surface temperature without contact but may produce less accurate results due to reflective sugar surfaces and varying heat distribution. For candying, a candy thermometer is generally preferred for its reliability in monitoring critical temperature stages.

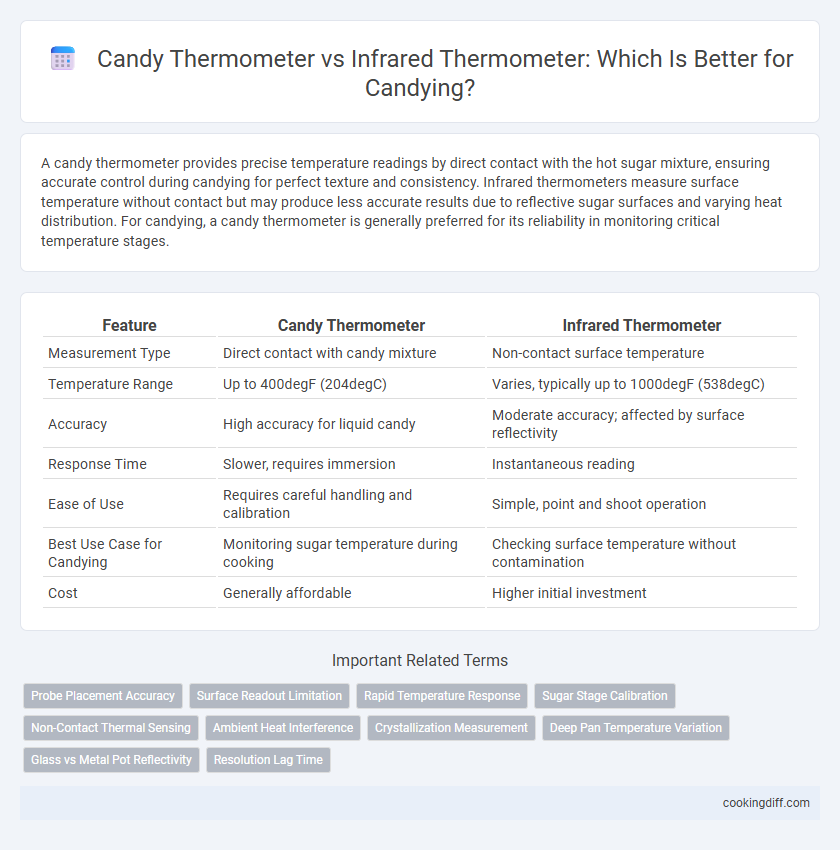

Table of Comparison

| Feature | Candy Thermometer | Infrared Thermometer |

|---|---|---|

| Measurement Type | Direct contact with candy mixture | Non-contact surface temperature |

| Temperature Range | Up to 400degF (204degC) | Varies, typically up to 1000degF (538degC) |

| Accuracy | High accuracy for liquid candy | Moderate accuracy; affected by surface reflectivity |

| Response Time | Slower, requires immersion | Instantaneous reading |

| Ease of Use | Requires careful handling and calibration | Simple, point and shoot operation |

| Best Use Case for Candying | Monitoring sugar temperature during cooking | Checking surface temperature without contamination |

| Cost | Generally affordable | Higher initial investment |

Understanding Candy Thermometers: Traditional Tools for Candying

Candy thermometers are essential traditional tools designed to measure precise temperatures needed for successful candying, typically ranging from 100degF to 400degF. They provide direct contact measurement, ensuring accurate readings during boiling and sugar crystallization stages.

Infrared thermometers, while useful for non-contact temperature reading, may give less consistent results due to surface temperature variations and reflections. Traditional candy thermometers offer greater reliability for monitoring exact sugar temperatures critical to achieving specific candy textures. Accurate temperature control with a traditional candy thermometer helps prevent crystallization errors and enhances candy quality.

How Infrared Thermometers Work in Cooking

Infrared thermometers measure temperature by detecting the infrared radiation emitted from the candy's surface, providing quick and non-contact readings essential for precise candying. Unlike candy thermometers that need direct immersion, infrared thermometers are useful for monitoring surface temperature without disturbing the cooking process.

- Non-contact Measurement - Infrared thermometers detect heat radiation from the candy surface, allowing accurate temperature readings without touching the substance.

- Instantaneous Readings - They provide rapid temperature measurements essential for timely adjustments during candying stages like soft ball or hard crack.

- Surface Temperature Focus - These thermometers measure only the exterior heat, which is ideal for monitoring caramel or sugar coatings but may not reflect internal temperatures accurately.

Accuracy Comparison: Candy vs Infrared Thermometers

Candy thermometers provide precise temperature readings crucial for sugar stages in candying, typically accurate within +/- 1degF. Infrared thermometers measure surface temperature only, often missing internal candy temperatures and leading to inconsistent results.

Accuracy in candy thermometers ensures proper caramelization and prevents crystallization, essential for perfect candy texture. Infrared thermometers are less reliable for candying due to their inability to measure sugar mixture temperature throughout.

Speed and Convenience in Temperature Readings

Candy thermometers provide direct, precise temperature readings by being immersed in the sugar solution, essential for achieving accurate stages like soft ball or hard crack in candying. Infrared thermometers offer rapid, non-contact temperature measurement, enhancing convenience and speed but may lack the depth accuracy required for thick or boiling mixtures. For tasks demanding exact thermal control, the candy thermometer remains indispensable despite infrared thermometers' speed advantage.

Usability: Handling Hot Sugar and Syrups

Candy thermometers offer direct immersion in hot sugar and syrups, ensuring accurate temperature readings critical for candying processes. Infrared thermometers provide non-contact measurement but can be less reliable due to surface reflections and inconsistent readings with translucent syrups.

- Direct Contact Measurement - Candy thermometers can withstand high temperatures while submerged in boiling sugar mixtures, providing precise monitoring.

- Non-Contact Convenience - Infrared thermometers allow measurement from a safe distance, reducing burn risk but may struggle with reflective or bubbling surfaces.

- Ease of Use During Cooking - Candy thermometers require continuous monitoring and careful handling, whereas infrared thermometers give quick readings but may need multiple scans to confirm accuracy.

Cleaning and Maintenance Considerations

Candy thermometers require thorough cleaning after each use to prevent sugar buildup and ensure accurate readings. Infrared thermometers demand minimal maintenance since they do not come into direct contact with sticky candy mixtures.

- Candy Thermometer Cleaning - Immersing the probe in warm soapy water helps remove crystallized sugar and residue effectively.

- Infrared Thermometer Maintenance - Wiping the lens with a soft, dry cloth maintains sensor accuracy without risking damage.

- Durability Considerations - Candy thermometers may need recalibration after frequent cleaning, while infrared models often require less frequent adjustments.

Choosing the right thermometer for candying depends on balancing ease of cleaning with precision needs.

Cost Differences: Which Thermometer Is More Budget-Friendly?

Candy thermometers are typically more budget-friendly, with prices ranging from $10 to $25, making them accessible for most home candy makers. Infrared thermometers, however, tend to be more expensive, often costing between $30 and $100 due to their advanced technology and versatility.

The lower price of candy thermometers makes them ideal for beginners and those who focus solely on candying. Infrared thermometers offer broader use cases but require a higher initial investment, which could deter budget-conscious users.

Best Practices for Candying with Each Thermometer

| Candy Thermometer | Provides continuous, direct contact temperature readings essential for precise sugar stage control, ranging from 100degF to 400degF. Best practice involves clip-on attachment to pot sides to monitor temperature throughout the cooking process, ensuring accurate detection of soft ball, hard crack, and caramel stages. Calibration before each use improves accuracy, preventing sugar crystallization or burning. |

| Infrared Thermometer | Offers instant, non-contact surface temperature measurements ideal for quick checks during candying without immersion. For best results, aim at the liquid surface at close range while avoiding reflective surfaces to minimize reading errors between 50degF and 1000degF. Periodic cross-verification with a candy thermometer ensures consistent temperature accuracy in sugar cooking. |

Safety Tips for Using Thermometers Around Hot Sugar

When candying, always use a candy thermometer designed to withstand high temperatures up to 400degF to ensure accurate readings and prevent accidents. Infrared thermometers are less reliable for measuring boiling sugar as they only read surface temperature and can lead to undercooked candy or burns. To enhance safety, avoid touching the hot sugar or pot, use a thermometer with a clip to secure it on the pan, and wear heat-resistant gloves while monitoring temperatures.

Related Important Terms

Probe Placement Accuracy

Candy thermometers with probes provide precise internal temperature readings by being directly immersed in the sugar mixture, ensuring consistent and accurate monitoring essential for perfect candy texture. Infrared thermometers measure surface temperature only, often leading to inaccurate readings in candying due to uneven heat distribution and lack of direct contact with the candy's core.

Surface Readout Limitation

Candy thermometers measure the temperature directly in the sugar mixture, providing accurate readings essential for precise candying stages, while infrared thermometers only gauge surface temperature, which can result in misleading data due to uneven heat distribution and cooling effects. Relying on infrared thermometers during candying risks under or overcooking since they do not account for the internal temperature critical for achieving the correct texture and consistency.

Rapid Temperature Response

Candy thermometers provide rapid temperature response essential for precise sugar stage monitoring in candying, detecting temperature changes quickly in boiling sugar solutions. Infrared thermometers offer non-contact readings but may lag in accuracy and response time when measuring hot, viscous candy mixtures.

Sugar Stage Calibration

Candy thermometers provide precise sugar stage calibration by directly measuring the temperature of the boiling sugar solution, ensuring accurate detection of critical stages like soft ball and hard crack. Infrared thermometers, while useful for surface temperature readings, often lack the accuracy and consistency required for reliable sugar stage calibration during candying processes.

Non-Contact Thermal Sensing

Infrared thermometers offer precise non-contact thermal sensing ideal for monitoring candy temperatures without risking contamination or disrupting the cooking process. Unlike traditional candy thermometers that require immersion in the mixture, infrared devices quickly measure surface heat, enhancing safety and efficiency in candying.

Ambient Heat Interference

Candy thermometers provide direct contact measurement crucial for accurate sugar temperature during candying, minimizing errors caused by ambient heat interference. Infrared thermometers, while non-contact and convenient, often give unreliable readings in candying due to fluctuating background temperatures affecting the surface temperature measurement.

Crystallization Measurement

Candy thermometers provide precise temperature readings crucial for monitoring sugar stages and preventing crystallization during candying, while infrared thermometers measure surface temperature and may not accurately reflect internal sugar temperature. Accurate crystallization control relies on the candy thermometer's ability to detect subtle temperature changes essential for achieving the desired candy texture and consistency.

Deep Pan Temperature Variation

Candy thermometers provide precise readings by being immersed directly into the sugar mixture, accurately capturing deep pan temperature variations essential for successful candying. Infrared thermometers, measuring surface temperature only, often miss critical fluctuations within the pan, leading to inconsistent candy texture and potential burning.

Glass vs Metal Pot Reflectivity

Candy thermometers, typically clipped to the side of a metal pot, measure temperature through direct contact with the candy mixture, ensuring accuracy despite metal pots' high reflectivity; infrared thermometers, however, detect surface temperature by measuring emitted infrared radiation, which can be skewed by the reflective surfaces of glass or metal pots, making them less reliable for candying. Metal pots reflect infrared radiation more than glass pots, causing inaccurate readings with infrared thermometers, whereas candy thermometers provide consistent and precise measurements essential for achieving the perfect candy texture.

Candy Thermometer vs Infrared Thermometer for candying. Infographic

cookingdiff.com

cookingdiff.com