Candying fruit creates a glossy, chewy texture that enhances desserts with a rich, tender bite, while dehydrated candy shells offer a crisp, brittle contrast that adds a satisfying crunch. The candying process preserves moisture, resulting in a soft interior that pairs well with creamy or soft components, whereas dehydrated shells provide a firm, shattering surface that accentuates textural complexity. Choosing between candying and dehydrated candy shells depends on the desired mouthfeel and balance of softness and crunch in the final dessert.

Table of Comparison

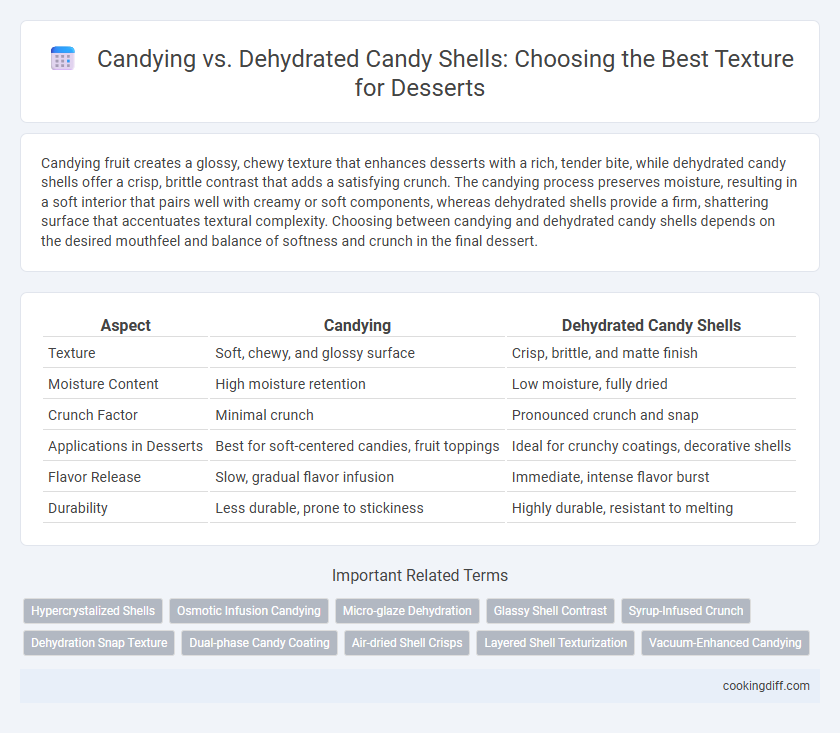

| Aspect | Candying | Dehydrated Candy Shells |

|---|---|---|

| Texture | Soft, chewy, and glossy surface | Crisp, brittle, and matte finish |

| Moisture Content | High moisture retention | Low moisture, fully dried |

| Crunch Factor | Minimal crunch | Pronounced crunch and snap |

| Applications in Desserts | Best for soft-centered candies, fruit toppings | Ideal for crunchy coatings, decorative shells |

| Flavor Release | Slow, gradual flavor infusion | Immediate, intense flavor burst |

| Durability | Less durable, prone to stickiness | Highly durable, resistant to melting |

Introduction to Candying and Dehydrated Candy Shells

Candying involves preserving fruits or nuts by soaking them in sugar syrup, creating a moist and flavorful texture that enhances dessert complexity. Dehydrated candy shells, on the other hand, provide a crisp and crunchy exterior by removing moisture through drying techniques, ideal for adding texture contrast in confections. Understanding the distinct methods of candying and dehydration helps pastry chefs craft desserts with balanced and appealing textures.

The Science Behind Candying Techniques

Candying involves infiltrating fruit or nuts with a sugar syrup, which crystallizes to create a smooth, glossy texture that preserves moisture and enhances flavor. Dehydrated candy shells rely on removing moisture to form a hard, brittle exterior that contrasts with softer dessert components. The science behind candying centers on controlling sugar saturation and moisture retention to achieve specific textural outcomes in dessert applications.

How Dehydrated Candy Shells Are Made

Dehydrated candy shells are created by removing moisture from a sugar syrup mixture, resulting in a crisp, glass-like texture. This process differs from candying, which involves infusing fruit with sugar to preserve and flavor it while maintaining a chewy consistency.

- Sugar syrup preparation - A sugar solution is boiled to reach the desired concentration before shaping.

- Dehydration phase - The candy shells are placed in a low-humidity environment or dehydrator to extract water content slowly.

- Texture formation - The removal of moisture solidifies the shell into a brittle, crunchy layer ideal for dessert toppings.

Dehydrated candy shells provide a unique crispy texture that contrasts with the softer bite of traditional candied fruit in desserts.

Texture Differences: Candying vs Dehydrated Shells

Candying preserves a chewy, glossy texture by infusing fruit with sugar syrup, creating a tender yet firm bite. Dehydrated candy shells develop a crisp, brittle exterior that adds a contrasting crunch to desserts.

- Chewiness vs Crispness - Candying results in a soft, pliable texture while dehydrated shells harden into a crackly surface.

- Moisture Retention - Candying retains moisture within the fruit, enhancing tenderness, whereas dehydration removes water to form a dry, crunchy coating.

- Application Variation - Candying suits garnishes needing chewability, while dehydrated shells provide a textural contrast ideal for layered desserts.

Flavor Impact on Desserts: A Comparative Analysis

Candied coatings provide a rich, intense sweetness and a slightly sticky texture that enhances the flavor complexity of desserts. In contrast, dehydrated candy shells offer a crisp, brittle exterior that delivers a sharper, cleaner sugar profile without overwhelming the palate.

Flavor impact from candying results in a layered tasting experience where the sugar syrup penetrates the dessert, enriching its moisture and depth. Dehydrated candy shells contribute a pronounced crunch and brightness, making them ideal for balancing creamy or dense dessert components. Both techniques alter the sensory perception, but candied coatings tend to amplify sweetness while dehydrated shells emphasize texture contrast.

Best Uses for Candied Ingredients in Pastry

Candied ingredients provide a glossy, chewy texture ideal for adding bursts of sweetness and moisture in pastries. Dehydrated candy shells contribute a crisp, brittle texture that enhances contrast in layered desserts or as decorative toppings.

- Candied fruits retain moisture - Perfect for filling tarts and cakes where a soft, flavorful bite is desired.

- Dehydrated candy shells offer crunch - Best used as garnishes on mousses and creamy desserts to add texture balance.

- Candied peels intensify aroma - Ideal for infusing pastries with citrusy, fragrant notes without overpowering.

Applications of Dehydrated Candy Shells in Modern Desserts

How do dehydrated candy shells enhance texture in modern desserts? Dehydrated candy shells provide a crisp, brittle outer layer that contrasts with soft or creamy fillings, elevating the sensory experience. Their versatility allows for use in plated desserts, ice creams, and pastry toppings, adding both visual appeal and a satisfying crunch.

Shelf Life and Storage Considerations

Candying preserves fruits by infusing them with sugar syrup, extending shelf life to several months when stored in airtight containers at room temperature. This method maintains a chewy, moist texture, unlike dehydrated candy shells which dry out the fruit and limit shelf life to a few weeks.

Dehydrated candy shells require cool, dry storage to prevent brittleness and moisture absorption, which can shorten their lifespan. Candied fruits are less susceptible to environmental moisture, making them more suitable for long-term storage in varied conditions.

Aesthetic Appeal: Visual Effects in Plating

| Candying | Creates a glossy, crystal-like texture that enhances the dessert's visual appeal with sparkling, translucent surfaces reflecting light attractively. |

| Dehydrated Candy Shells | Offer a matte, structured finish that adds contrast and depth to plating, providing a refined and less reflective surface texture for elegant presentation. |

| Aesthetic Appeal: Visual Effects in Plating | Candying emphasizes brilliance and vibrancy through translucency and sparkling sugar crystals, whereas dehydrated candy shells contribute sophistication via muted tones and crisp edges, enabling diverse design styles in dessert plating. |

Related Important Terms

Hypercrystalized Shells

Hypercrystallized shells in candying create a uniquely glossy, crunchy texture that enhances dessert presentation and provides a satisfying snap distinct from the chewier consistency of dehydrated candy shells. This hypercrystallization process forms dense sugar crystals, resulting in a durable, brittle coating that maintains structural integrity under moisture, unlike dehydrated shells which may soften or become sticky.

Osmotic Infusion Candying

Osmotic infusion candying enhances texture in desserts by penetrating fruit with sugar solutions, creating a tender yet firm bite distinct from the crispness of dehydrated candy shells. This method preserves moisture while achieving a balanced chewiness, offering a richer mouthfeel compared to the brittle exterior produced by dehydration techniques.

Micro-glaze Dehydration

Micro-glaze dehydration enhances candying by creating a thin, crisp candy shell that offers a smooth, glossy finish and prevents moisture loss in desserts, unlike traditional dehydrated candy shells which tend to be brittle and prone to cracking. This advanced technique preserves flavor integrity while providing a consistent, crunchy texture that elevates the overall sensory experience in confectionery applications.

Glassy Shell Contrast

Candying produces a glassy, translucent shell with a crisp yet tender bite that enhances the dessert's texture through a satisfying contrast between the smooth interior and the shiny exterior. Dehydrated candy shells tend to have a drier, more brittle texture, resulting in a less flexible but intensely crunchy glass-like coating that offers a sharper textural differentiation in desserts.

Syrup-Infused Crunch

Candying creates syrup-infused crunch by saturating fruit or nuts with sugar syrup, preserving moisture while forming a glossy, tender shell that enhances texture in desserts. Dehydrated candy shells rely on drying techniques, resulting in a harder, brittle exterior that offers a contrasting crispness but lacks the moist, syrupy depth provided by candying.

Dehydration Snap Texture

Dehydrated candy shells offer a distinctive snap texture that enhances the contrast in desserts, providing a crisp bite that complements creamy or soft components. Unlike candied coatings, which often have a glossy, sticky finish, dehydrated shells maintain a firm, brittle structure that elevates the sensory experience through a satisfying crunch.

Dual-phase Candy Coating

Dual-phase candy coating combines the glossy, hard texture of candying with the light crunch of dehydrated candy shells, creating a multi-dimensional mouthfeel that enhances desserts. This method preserves intense flavor bursts while providing a balanced contrast between crispness and chewiness, ideal for sophisticated confectionery creations.

Air-dried Shell Crisps

Air-dried shell crisps in candying create a delicate, airy texture that enhances the mouthfeel in desserts, providing a light crunch without the hardness typical of dehydrated candy shells. This technique preserves the natural flavors and colors of the ingredients while delivering a crisp, melt-in-the-mouth experience superior to conventional dehydrated coatings.

Layered Shell Texturization

Candying creates a smooth, glossy shell with a crisp bite that enhances layered desserts by adding a delicate contrast between crunchy exterior and soft interior. Dehydrated candy shells offer a more brittle, chalky texture that breaks unevenly, contributing a rustic, fragmented layer rather than a uniform, glass-like surface.

Candying vs Dehydrated Candy Shells for texture in desserts. Infographic

cookingdiff.com

cookingdiff.com