Candying preserves fruits by slowly cooking them in sugar syrup, resulting in a sweet, chewy texture ideal for traditional recipes. Ultrasonic candying uses high-frequency sound waves to accelerate sugar absorption, producing evenly candied fruits with enhanced flavor and reduced cooking time. This modern technique offers greater efficiency and consistent quality compared to conventional candying methods.

Table of Comparison

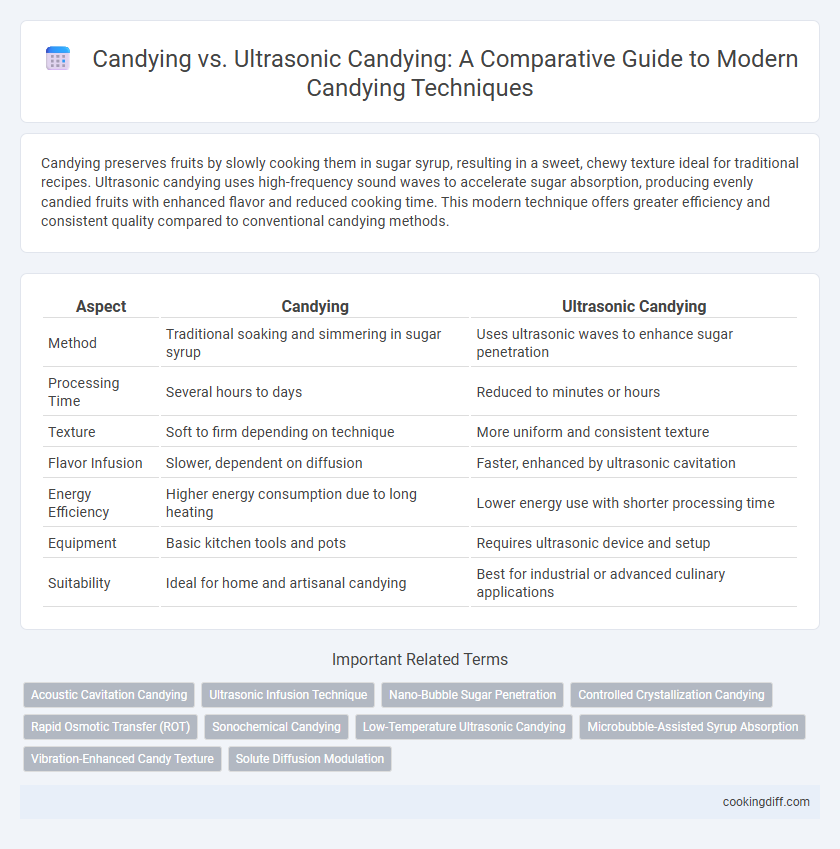

| Aspect | Candying | Ultrasonic Candying |

|---|---|---|

| Method | Traditional soaking and simmering in sugar syrup | Uses ultrasonic waves to enhance sugar penetration |

| Processing Time | Several hours to days | Reduced to minutes or hours |

| Texture | Soft to firm depending on technique | More uniform and consistent texture |

| Flavor Infusion | Slower, dependent on diffusion | Faster, enhanced by ultrasonic cavitation |

| Energy Efficiency | Higher energy consumption due to long heating | Lower energy use with shorter processing time |

| Equipment | Basic kitchen tools and pots | Requires ultrasonic device and setup |

| Suitability | Ideal for home and artisanal candying | Best for industrial or advanced culinary applications |

Introduction to Candying and Ultrasonic Candying

| Candying | Candying is a traditional cooking method that involves preserving fruits or vegetables by slowly cooking them in sugar syrup until they become saturated with sugar, enhancing flavor and shelf life. |

| Ultrasonic Candying | Ultrasonic candying uses high-frequency sound waves to accelerate the absorption of sugar syrup into the food, reducing processing time and improving texture uniformity compared to conventional candying methods. |

The Science Behind Traditional Candying

Traditional candying relies on the process of osmosis, where sugar penetrates the fruit to replace water content, preserving its texture and flavor. Heating the sugar syrup gently allows for gradual absorption, leading to a stable sugar crystal formation that enhances shelf life.

Ultrasonic candying, however, uses high-frequency sound waves to accelerate sugar infusion by creating microscopic cavitation bubbles in the fruit's tissues. This method results in faster candying times while maintaining the structural integrity of the fruit.

How Ultrasonic Candying Works

How does ultrasonic candying differ in its process from traditional candying methods? Ultrasonic candying utilizes high-frequency sound waves to create microscopic bubbles that rapidly infuse sugar solutions into fruits, enhancing flavor absorption. This innovative technique significantly reduces processing time and improves texture compared to conventional soaking or boiling methods.

Key Differences Between Candying and Ultrasonic Candying

Candying involves soaking fruit in sugar syrup over an extended period to preserve and flavor it, relying primarily on diffusion and slow absorption. Ultrasonic candying uses high-frequency sound waves to accelerate sugar penetration, significantly reducing processing time while maintaining texture and taste.

Traditional candying is labor-intensive and time-consuming, often taking days to complete, whereas ultrasonic candying achieves similar results within hours. Ultrasonic methods enhance sugar crystallization uniformity and improve flavor infusion without the need for high temperatures, preserving delicate fruit properties better than conventional techniques.

Equipment Needed: Traditional vs Ultrasonic Methods

Traditional candying requires basic kitchen tools such as pots, thermometers, and utensils for stirring and soaking ingredients in sugar syrup. Ultrasonic candying involves specialized equipment, including an ultrasonic cleaner or ultrasonic probe, to enhance sugar infusion.

While traditional methods rely on precise temperature control and extended soaking times, ultrasonic candying uses high-frequency sound waves to accelerate the process and improve texture uniformity. The ultrasonic device equipment is typically more costly but offers greater efficiency and consistency. Understanding the equipment differences is crucial for selecting the appropriate candying method based on available resources and desired outcomes.

Flavor and Texture Outcomes Compared

Candying infuses fruits with syrup through slow cooking, resulting in a classic chewy texture and rich, sweet flavor. Ultrasonic candying utilizes high-frequency sound waves to enhance sugar absorption, producing a more uniform texture and intensified flavor profile.

- Candying - Develops a firmer, denser texture by gradually crystallizing sugar on the fruit surface.

- Ultrasonic Candying - Promotes deeper penetration of syrup, enhancing juiciness without compromising the fruit's natural softness.

- Flavor Outcomes - Traditional candying enhances sweetness, while ultrasonic methods preserve and amplify the fruit's original aromatic notes.

Ultrasonic candying offers a more efficient technique delivering superior flavor retention and a refined texture compared to conventional candying methods.

Time and Efficiency: Manual vs Ultrasonic

Candying manually requires extended soaking and slow simmering to infuse syrup deeply, leading to longer preparation times. Ultrasonic candying accelerates sugar penetration by using high-frequency waves, significantly reducing the cooking duration while maintaining quality.

- Manual candying is time-intensive - Traditional methods involve hours of simmering and periodic checks to ensure even syrup absorption.

- Ultrasonic candying enhances efficiency - Ultrasonic waves create micro-vibrations that speed up syrup diffusion into the fruit.

- Ultrasonic method lowers energy usage - Faster processing decreases overall cooking time, conserving heat and resources.

Applications in Modern Cooking

Candying preserves fruits by slowly infusing sugar, enhancing texture and flavor suitable for traditional desserts and confectioneries. Ultrasonic candying accelerates this process using high-frequency sound waves, improving sugar penetration and reducing cooking time, ideal for large-scale or precision gastronomy applications. Modern kitchens benefit from ultrasonic candying's efficiency and consistency, while classic candying remains valued for artisanal quality in gourmet recipes.

Challenges and Limitations of Each Method

Candying involves slow cooking with sugar syrup, often leading to uneven absorption and longer preparation times due to the gradual process. Ultrasonic candying uses high-frequency sound waves to accelerate sugar penetration, but it requires specialized equipment and can sometimes cause texture changes in delicate fruits. Both methods face challenges in balancing flavor infusion and maintaining the desired consistency while preventing crystallization or over-softening of the candy.

Related Important Terms

Acoustic Cavitation Candying

Acoustic cavitation candying utilizes ultrasonic waves to create microscopic bubbles that implode, enhancing sugar infusion and accelerating the candying process compared to traditional methods. This technique improves texture uniformity and flavor absorption by promoting deeper penetration of syrup into the fruit matrix through controlled cavitation dynamics.

Ultrasonic Infusion Technique

Ultrasonic infusion technique enhances candying by using high-frequency sound waves to create microbubbles that improve flavor penetration and reduce infusion time significantly. This method ensures uniform absorption of syrups and spices, resulting in superior texture and intensified taste compared to traditional candying processes.

Nano-Bubble Sugar Penetration

Candying using traditional methods relies on sugar diffusion driven by osmotic pressure, whereas ultrasonic candying enhances sugar penetration by generating nano-bubbles that create micro-jets and cavitation, significantly improving infusion efficiency. Nano-bubble technology in ultrasonic candying accelerates sugar absorption into the food matrix, leading to a more uniform and rapid flavor infusion compared to conventional candying techniques.

Controlled Crystallization Candying

Controlled Crystallization candying ensures uniform sugar crystal formation on fruits, enhancing texture and flavor retention during cooking. Ultrasonic candying accelerates this process by promoting rapid sugar penetration and even crystallization, resulting in more consistent and higher-quality candied products.

Rapid Osmotic Transfer (ROT)

Candying relies on traditional slow osmotic transfer to infuse sugar into fruits, whereas Ultrasonic Candying enhances Rapid Osmotic Transfer (ROT) by using ultrasonic waves to accelerate sugar permeation and moisture removal. This advanced technique significantly reduces processing time while maintaining texture and flavor integrity in the candied products.

Sonochemical Candying

Sonochemical candying utilizes ultrasonic waves to enhance the infusion of sugar and flavor into fruits, resulting in faster processing times and superior texture retention compared to traditional candying methods. This ultrasonic technique promotes more uniform sugar penetration through cavitation effects, optimizing sweetness distribution and preserving nutritional content.

Low-Temperature Ultrasonic Candying

Low-Temperature Ultrasonic Candying enhances traditional candying by using ultrasonic waves to accelerate sugar infusion at lower temperatures, preserving delicate flavors and textures while reducing cooking time. This method improves the absorption rate of syrups in fruits, resulting in a higher-quality candied product with better clarity and moisture retention compared to conventional candying techniques.

Microbubble-Assisted Syrup Absorption

Microbubble-assisted syrup absorption in ultrasonic candying enhances flavor penetration and texture uniformity by generating microbubbles that improve syrup infusion into the fruit's cellular structure. This technique outperforms traditional candying by accelerating syrup uptake and preserving the fruit's natural shape and nutritional content.

Vibration-Enhanced Candy Texture

Vibration-enhanced candying uses ultrasonic waves to create uniform sugar penetration, resulting in a firmer, more consistent texture compared to traditional candying methods. Ultrasonic candying improves crystal structure by reducing sugar granule size, producing a smoother, less grainy candy surface.

Candying vs Ultrasonic Candying for cooking. Infographic

cookingdiff.com

cookingdiff.com