A cooling rack allows air to circulate evenly around candy pieces, preventing moisture buildup and ensuring a crisp texture during the candying process. Perforated trays also promote airflow but may retain more heat and humidity, which can affect the candy's finish. Choosing a cooling rack is ideal for achieving a consistent, dry surface while a perforated tray offers convenience and sturdiness for larger batches.

Table of Comparison

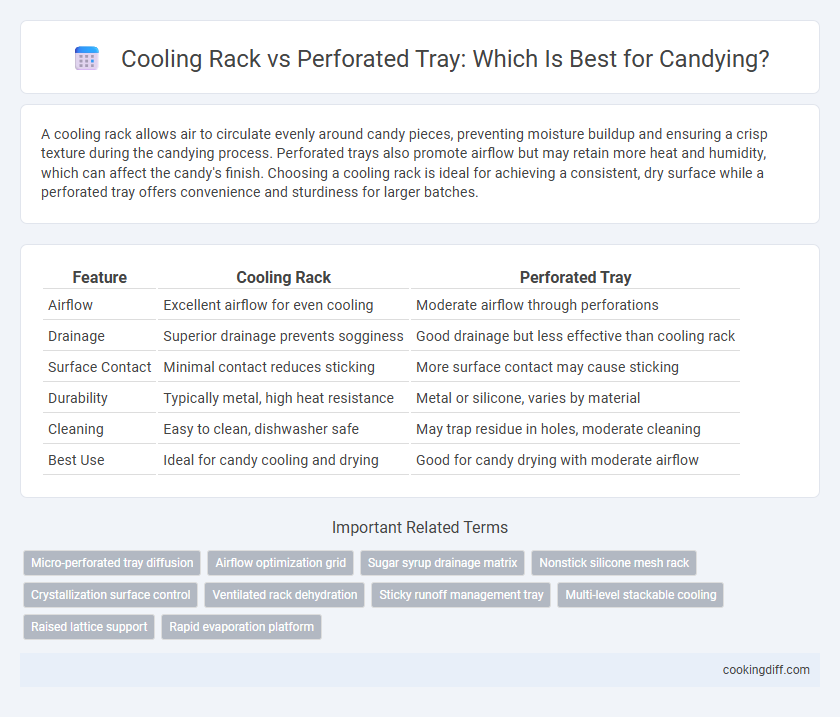

| Feature | Cooling Rack | Perforated Tray |

|---|---|---|

| Airflow | Excellent airflow for even cooling | Moderate airflow through perforations |

| Drainage | Superior drainage prevents sogginess | Good drainage but less effective than cooling rack |

| Surface Contact | Minimal contact reduces sticking | More surface contact may cause sticking |

| Durability | Typically metal, high heat resistance | Metal or silicone, varies by material |

| Cleaning | Easy to clean, dishwasher safe | May trap residue in holes, moderate cleaning |

| Best Use | Ideal for candy cooling and drying | Good for candy drying with moderate airflow |

Introduction to Candying Techniques

Cooling racks and perforated trays serve distinct roles in candying techniques by facilitating airflow and moisture escape. Proper air circulation is crucial to achieve the desired texture and prevent sogginess in candied fruits or nuts.

Cooling racks allow excess syrup to drip away while exposing the candy to air on all sides, promoting even drying and crystallization. Perforated trays enhance ventilation through small holes but may limit drainage compared to racks. Choosing the right tool depends on the candying process and the type of ingredient being candied.

Overview of Cooling Racks and Perforated Trays

What are the differences between cooling racks and perforated trays for candying? Cooling racks elevate candies, allowing air to circulate evenly for optimal cooling and preventing sticking. Perforated trays feature holes that facilitate drainage of excess syrup, enhancing texture and preventing sogginess in the candying process.

Design and Structure: Cooling Rack vs Perforated Tray

Cooling racks feature an elevated grid design that allows air to circulate evenly around the candy, preventing sogginess and promoting faster cooling. Perforated trays have a solid base with holes, providing stability while allowing some airflow, but less efficient ventilation compared to cooling racks.

- Cooling Rack Design - Elevated grids facilitate 360-degree air circulation for consistent candy cooling.

- Perforated Tray Structure - Solid base with strategically placed holes offers stable support with moderate airflow.

- Airflow Efficiency - Cooling racks outperform perforated trays by enabling better ventilation and drying during candying.

Airflow and Even Drying in Candying

Cooling racks provide superior airflow beneath candy, promoting even drying by allowing air to circulate freely around the pieces. Perforated trays offer some airflow but can restrict circulation, potentially causing uneven drying and longer setting times.

- Cooling Rack Airflow Advantage - Elevated design ensures maximum air circulation, preventing moisture buildup under candies.

- Perforated Tray Limitations - Perforations are often smaller and less effective at allowing airflow compared to open cooling racks.

- Impact on Drying Consistency - Better airflow on cooling racks leads to uniform drying and crisp candy texture, reducing risk of sticky or soggy spots.

Ease of Use and Handling

Cooling racks provide excellent air circulation around candy, allowing for even cooling and preventing sogginess. Their elevated structure makes handling easier, especially when transferring sticky or delicate candies.

Perforated trays offer a solid surface with small holes, which helps contain smaller candy pieces while still allowing some airflow. They require less space and can be easier to clean, but handling can be trickier due to the lack of elevation.

Clean-Up and Maintenance Comparison

Cooling racks typically have open wires that allow excess syrup to drip off, making initial cleaning straightforward but requiring more attention to prevent sticky residue buildup in the crevices. Perforated trays feature small holes that also allow drainage but tend to trap candy bits, necessitating thorough scrubbing during cleanup.

Maintenance of cooling racks is generally easier since they can be quickly rinsed and wiped down, though they may require occasional deep cleaning to remove hardened sugar. Perforated trays demand more detailed maintenance to clear trapped debris, but their solid surfaces often withstand regular dishwasher cycles without damage.

Impact on Candy Texture and Finish

| Cooling Rack | Allows air to circulate evenly around candies, promoting consistent drying and a crisp texture; prevents sogginess by lifting sweets off the surface. |

|---|---|

| Perforated Tray | Facilitates drainage of excess syrup but may cause uneven drying and stickiness due to limited airflow beneath the candies. |

| Texture & Finish Impact | Cooling racks produce a firm, glossy finish with uniform texture while perforated trays risk softer, tackier surfaces with potential drying inconsistencies. |

Versatility for Different Candy Types

Cooling racks offer superior airflow, making them ideal for candying delicate confections like caramel and toffee that require even cooling without moisture buildup. Perforated trays provide a stable surface, better suited for sticky or gummy candies that need support to maintain shape during the cooling process. Choosing between the two depends on the candy type's texture and cooling requirements, with cooling racks enhancing crispness and perforated trays ensuring structural integrity.

Cost Considerations and Accessibility

Cooling racks typically offer a more affordable option for candying due to their widespread availability and simple design. Perforated trays, while often pricier, provide enhanced airflow that can improve candy texture but may not be necessary for basic candying needs. Accessibility to cooling racks is higher as they are commonly found in most kitchens, whereas perforated trays might require specialty baking supply stores or online purchasing.

Related Important Terms

Micro-perforated tray diffusion

Micro-perforated trays enhance candying by allowing superior airflow and moisture diffusion compared to traditional cooling racks, resulting in evenly dried and crisply textured candies. The tiny perforations facilitate consistent heat distribution and evaporative cooling, reducing sticky surfaces and improving overall candy quality.

Airflow optimization grid

A cooling rack with an optimized airflow grid allows maximum air circulation around candied items, promoting even drying and preventing moisture buildup, which is essential for achieving a crisp texture. In contrast, a perforated tray provides limited airflow due to smaller holes and a flatter surface, potentially resulting in uneven cooling and longer drying times during candying.

Sugar syrup drainage matrix

A cooling rack provides optimal sugar syrup drainage during candying by allowing excess syrup to drip away through its open grid, preventing sogginess and promoting even drying. In contrast, a perforated tray's limited holes can trap syrup beneath the candy, risking uneven texture and longer drying times.

Nonstick silicone mesh rack

Nonstick silicone mesh racks provide superior airflow and prevent sticking during candying, ensuring even cooling and flawless candy texture. Unlike traditional cooling racks or perforated trays, silicone mesh racks offer flexible, durable surfaces that simplify candy removal and enhance overall candy quality.

Crystallization surface control

Using a cooling rack during candying allows air circulation around the candy, promoting even crystallization and preventing moisture buildup, which ensures a consistent surface texture. In contrast, a perforated tray offers limited airflow control, potentially leading to irregular crystallization patterns and uneven candy surfaces.

Ventilated rack dehydration

A cooling rack with ventilated design promotes efficient airflow around candy, accelerating dehydration and preventing sogginess during candying. Unlike perforated trays, cooling racks minimize contact points, ensuring uniform drying and better texture preservation.

Sticky runoff management tray

A perforated tray excels in sticky runoff management during candying by allowing excess syrup to drip through the holes, preventing candies from sitting in sticky residue and ensuring even cooling and drying. Cooling racks without perforations often trap syrup beneath the candies, resulting in uneven texture and increased cleanup challenges.

Multi-level stackable cooling

Multi-level stackable cooling racks provide superior airflow around candied items, ensuring even drying and consistent texture by allowing air to circulate beneath and between layers. Perforated trays offer similar airflow benefits but often lack the vertical stacking capability, limiting overall cooling capacity in compact kitchen spaces.

Raised lattice support

A cooling rack with raised lattice support allows optimal air circulation around candy, promoting even cooling and preventing sogginess during candying. In contrast, a perforated tray offers drainage but lacks the elevated structure, which may result in uneven cooling and sticky spots on delicate confections.

Cooling Rack vs Perforated Tray for candying. Infographic

cookingdiff.com

cookingdiff.com