When candying pet treats, precise temperature control is essential for achieving the perfect texture and safety. Metal thermometers provide accurate, consistent direct contact readings ideal for thick syrups, while infrared thermometers offer quick, non-contact surface temperature measurements that prevent contamination. Choosing the right thermometer depends on whether you prioritize accuracy in the liquid's core or the convenience of rapid surface checks.

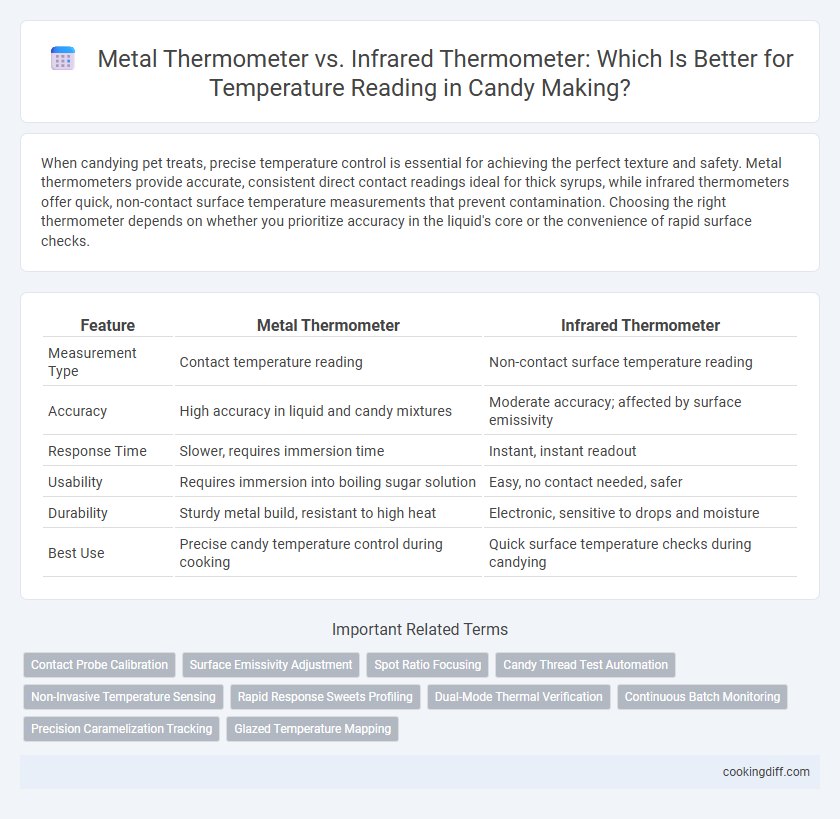

Table of Comparison

| Feature | Metal Thermometer | Infrared Thermometer |

|---|---|---|

| Measurement Type | Contact temperature reading | Non-contact surface temperature reading |

| Accuracy | High accuracy in liquid and candy mixtures | Moderate accuracy; affected by surface emissivity |

| Response Time | Slower, requires immersion time | Instant, instant readout |

| Usability | Requires immersion into boiling sugar solution | Easy, no contact needed, safer |

| Durability | Sturdy metal build, resistant to high heat | Electronic, sensitive to drops and moisture |

| Best Use | Precise candy temperature control during cooking | Quick surface temperature checks during candying |

Introduction: Importance of Accurate Temperature in Candying

Accurate temperature measurement is crucial in candying to achieve the desired texture and avoid crystallization. Metal thermometers provide direct contact readings, ensuring precise temperature control in the boiling sugar mixture.

Infrared thermometers offer a non-contact method, measuring surface temperature quickly and safely but may be less accurate for thick or uneven substances. Choosing the right thermometer enhances consistency and quality in candy production.

Overview: Metal Thermometers and Infrared Thermometers

Metal thermometers provide direct and accurate temperature readings by being immersed in the candy mixture, ensuring precise control over sugar stages. Infrared thermometers offer quick surface temperature measurements without contact, ideal for fast checks but less precise for internal candy temperatures.

- Metal Thermometer Accuracy - Measures internal temperature by immersion, crucial for consistent candy texture.

- Infrared Thermometer Speed - Provides instant surface temperature readings, useful for rapid monitoring.

- Use Case Suitability - Metal thermometers excel in precise cooking, while infrared suits quick assessments.

How Metal Thermometers Work in Candying

Metal thermometers measure temperature by sensing the expansion of a metal coil inside the device, which moves the needle to indicate the precise heat level. This method provides accurate real-time readings essential for controlling sugar stages in candying.

- Direct Contact - Metal thermometers require immersion in the hot syrup to measure temperature accurately.

- Durability - The sturdy metal construction allows them to withstand high temperatures common in candying processes.

- Calibration - They can be easily calibrated to ensure consistent temperature readings during candy making.

Metal thermometers remain reliable tools for precise temperature monitoring in traditional candying techniques.

How Infrared Thermometers Function in Candy Making

How do infrared thermometers function in candy making? Infrared thermometers measure surface temperature by detecting the thermal radiation emitted from the candy's surface, allowing for quick and non-contact readings. This method prevents contamination and provides accurate temperature readings essential for achieving the correct candy stage.

Temperature Accuracy: Metal vs Infrared Thermometers

| Thermometer Type | Temperature Accuracy | Suitability for Candying |

|---|---|---|

| Metal Thermometer | High accuracy due to direct contact with sugar solution, providing precise temperature readings within +-1degF. | Ideal for candying as it measures the exact temperature needed to achieve specific sugar stages like soft ball or hard crack. |

| Infrared Thermometer | Less accurate for candying since it measures surface temperature and can be affected by steam or reflections, resulting in variable readings. | Less reliable for candy making where precise internal temperature control of the sugar mixture is essential for optimal results. |

Response Time: Comparing Metal and Infrared Devices

Metal thermometers typically have a slower response time because they rely on physical contact to measure temperature, which can delay readings during candying. Infrared thermometers provide instant, non-contact readings by detecting surface temperature, allowing for faster adjustments in candy-making. Rapid response times in infrared devices enhance precision and reduce the risk of overheating or undercooking sugar mixtures.

Ease of Use and Practicality in the Kitchen

Metal thermometers offer precise temperature readings by being immersed directly in syrup, making them a reliable choice for candying but requiring careful handling to avoid burns. Infrared thermometers provide quick, non-contact temperature measurements, enhancing kitchen safety and ease of use during the candy-making process.

While metal thermometers need constant monitoring and stirring to ensure accurate syrup temperature, their durability suits prolonged cooking sessions. Infrared thermometers excel in practicality with instant readings and minimal cleanup, although they may be less accurate on reflective or uneven surfaces common in candying.

Cleaning and Maintenance Requirements

Metal thermometers require thorough cleaning after each use, as they come into direct contact with sugary substances that can crystallize and affect accuracy. Infrared thermometers, being non-contact devices, have lower cleaning demands limited mainly to wiping the sensor lens. Proper maintenance of metal thermometers involves regular calibration to prevent rust and residue buildup, while infrared thermometers need occasional lens cleaning to ensure precise temperature readings.

Cost Comparison: Metal vs Infrared Thermometers

Metal thermometers typically cost less upfront, ranging from $5 to $15, making them an economical choice for candying processes. Infrared thermometers, priced between $30 and $100, represent a higher initial investment but offer non-contact temperature measurement.

While metal thermometers are affordable and reliable for direct immersion, their use requires manual handling and potential heat exposure. Infrared thermometers provide quick readings without contacting hot surfaces, reducing safety risks. Over time, the durability and convenience of infrared models may justify their higher cost for frequent candying applications.

Related Important Terms

Contact Probe Calibration

Metal thermometers with contact probes provide precise calibration essential for accurate temperature readings during candying, ensuring direct heat transfer and consistent monitoring of sugar stages. Infrared thermometers, while offering non-contact convenience, may lack the accuracy of metal probe calibration due to surface emissivity variability and limited penetration.

Surface Emissivity Adjustment

Metal thermometers provide direct contact temperature readings but require calibration for surface emissivity when measuring candying temperatures accurately. Infrared thermometers allow non-contact surface temperature measurement with adjustable emissivity settings, enabling precise monitoring of sugar temperatures without contamination risks.

Spot Ratio Focusing

Metal thermometers provide direct contact measurements ideal for candying, ensuring accurate temperature readings without reliance on spot ratio focusing. Infrared thermometers use spot ratio focusing to measure surface temperature from a distance, but their accuracy can be compromised by the small size and reflective surfaces of candy mixtures.

Candy Thread Test Automation

Metal thermometers provide precise contact-based temperature readings essential for accurate candy thread tests, ensuring consistent syrup stages during candying processes. Infrared thermometers offer rapid, non-contact measurements ideal for quick surface temperature checks but may lack the specificity needed for automated thread test accuracy in candy production.

Non-Invasive Temperature Sensing

Infrared thermometers provide non-invasive temperature sensing by measuring surface heat emissions without direct contact, which prevents contamination and preserves candy quality during the cooking process. Metal thermometers require insertion into the candy mixture, posing a higher risk of contamination and potential damage to delicate candy textures.

Rapid Response Sweets Profiling

Metal thermometers provide precise temperature readings essential for candying, but infrared thermometers offer rapid response and non-contact measurement ideal for profiling sweets without contaminating delicate confections. Infrared thermometers enable efficient temperature monitoring of surface temperatures, enhancing control over caramelization and crystallization processes critical to candy quality.

Dual-Mode Thermal Verification

Dual-mode thermal verification combines metal and infrared thermometer readings to enhance accuracy and consistency in candying temperature control. Metal thermometers provide direct contact data essential for precise sugar concentration, while infrared thermometers enable quick surface temperature measurements, ensuring efficient thermal monitoring during the candying process.

Continuous Batch Monitoring

Metal thermometers provide accurate, continuous temperature readings essential for precise candying processes, enabling real-time monitoring of sugar syrup temperatures during batch cooking. Infrared thermometers offer non-contact surface measurements but lack the ability to continuously track internal temperature fluctuations, making them less effective for continuous batch monitoring in candy production.

Precision Caramelization Tracking

A metal thermometer offers precise, direct contact measurement crucial for accurate caramelization tracking in candying, ensuring the sugar reaches exact temperatures. Infrared thermometers provide quick, non-contact readings but may lack the accuracy needed for consistent caramelization stages due to surface temperature variations.

Metal Thermometer vs Infrared Thermometer for temperature reading. Infographic

cookingdiff.com

cookingdiff.com