Candying preserves food by saturating it with sugar to inhibit microbial growth, while infrared candying accelerates this process using infrared heat, reducing drying time and energy consumption. Infrared candying enhances sugar penetration and moisture removal more efficiently than traditional methods, resulting in faster, more uniform preservation. This technology offers a modern alternative for quicker candying without compromising quality or taste.

Table of Comparison

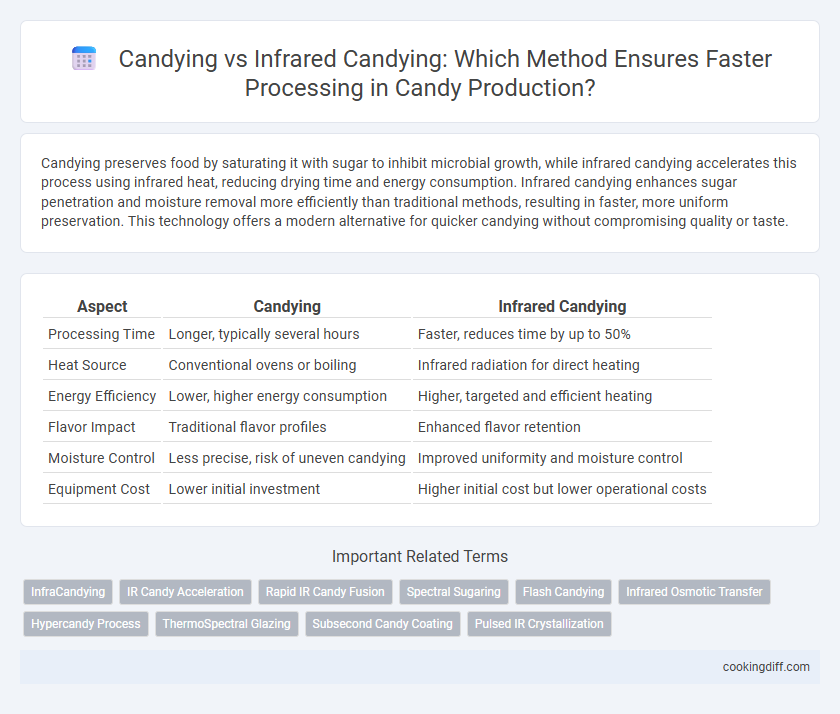

| Aspect | Candying | Infrared Candying |

|---|---|---|

| Processing Time | Longer, typically several hours | Faster, reduces time by up to 50% |

| Heat Source | Conventional ovens or boiling | Infrared radiation for direct heating |

| Energy Efficiency | Lower, higher energy consumption | Higher, targeted and efficient heating |

| Flavor Impact | Traditional flavor profiles | Enhanced flavor retention |

| Moisture Control | Less precise, risk of uneven candying | Improved uniformity and moisture control |

| Equipment Cost | Lower initial investment | Higher initial cost but lower operational costs |

Introduction to Candying: Traditional vs Modern Methods

Candiying is a preservation technique involving the infusion of sugar into fruits to extend shelf life and enhance flavor. Traditional candying uses slow, low-temperature boiling to allow gradual sugar absorption, while modern infrared candying employs infrared radiation to speed up the process by rapidly heating the fruit's surface. Infrared candying offers significant time savings and improved energy efficiency without compromising the quality or texture of the candied product.

What is Conventional Candying?

Conventional candying involves slowly immersing fruits in sugar syrup to replace water content, preserving texture and sweetness. This traditional method relies on osmotic dehydration, requiring extended processing times to achieve full infusion.

The process typically takes several hours to days, gradually infusing sugar molecules into the fruit's cellular structure. Temperature control and syrup concentration are critical parameters that influence the quality and shelf-life of the candied product. Despite longer processing times, conventional candying ensures uniform sweetness and tender texture essential for high-quality confectionery.

How Infrared Candying Works

Infrared candying employs infrared radiation to penetrate food items, accelerating the heat transfer process compared to traditional candying methods that rely on convection and conduction. This advanced technique enhances sugar absorption by heating the product more uniformly and rapidly.

The infrared waves target water molecules within the food, causing them to vibrate and generate internal heat, which speeds up the dehydration and candying process. As a result, infrared candying significantly reduces processing time while maintaining texture and flavor quality.

Speed Comparison: Traditional vs Infrared Candying

Infrared candying significantly accelerates the candying process by using radiant heat to penetrate the fruit more efficiently than traditional methods. This enhanced heat transfer reduces processing time while maintaining quality and flavor integrity.

- Heat Penetration - Infrared candying uses radiant heat that quickly penetrates the fruit, speeding up sugar absorption.

- Processing Time - Traditional candying can take several hours, whereas infrared candying cuts this time by up to 50% or more.

- Energy Efficiency - Infrared candying consumes less energy due to faster processing, lowering overall operational costs.

Quality and Texture in Candying Methods

| Candying using traditional methods preserves fruit texture by slow syrup absorption but often results in longer processing times and varying quality levels. Infrared candying accelerates sugar penetration by applying high-frequency waves, enhancing consistency and maintaining superior fruit firmness and color uniformity. Quality improvements in infrared candying include reduced moisture loss and minimized structural damage, leading to a premium texture and taste compared to conventional candying. |

Energy Efficiency: Traditional vs Infrared

How does energy efficiency compare between traditional candying and infrared candying methods? Traditional candying relies on prolonged heat exposure, consuming higher amounts of energy over extended periods. Infrared candying uses targeted heat transfer, significantly reducing energy consumption and processing time.

Equipment and Cost Considerations

Candying using traditional methods requires bulkier equipment with longer processing times, leading to higher energy consumption. Infrared candying technology utilizes compact, energy-efficient systems that significantly reduce processing duration and operational costs.

- Equipment Size - Traditional candying demands larger tanks and extensive heating elements compared to the compact infrared setups.

- Energy Consumption - Infrared candying consumes less energy by directly targeting the product, minimizing heat loss.

- Initial Investment - Infrared equipment has a higher upfront cost but lowers long-term expenses due to efficiency gains.

Nutrient Retention: Examining Both Techniques

Candying preserves fruit nutrients by slowly infusing sugar, while infrared candying enhances nutrient retention through rapid, uniform heating. Infrared candying reduces processing time, minimizing nutrient degradation compared to traditional candying methods.

- Traditional Candying - Retains vitamins but involves longer heat exposure, risking nutrient loss.

- Infrared Candying - Utilizes shorter heating durations, preserving antioxidants more effectively.

- Nutrient Stability - Infrared methods maintain higher levels of heat-sensitive compounds like vitamin C.

Infrared candying offers a nutrient-preserving alternative to conventional candying by accelerating processing times and reducing thermal damage.

Application Suitability: Fruits, Nuts, and More

Candied fruits and nuts achieve optimal texture and flavor through traditional candying, which gently infuses sugar over extended periods, ideal for delicate items like cherries and almonds. Infrared candying accelerates sugar absorption by using high-intensity radiation, enhancing processing speed while retaining the natural color and nutrients in fruits such as strawberries and apricots.

Traditional candying suits a wide range of applications, including soft fruits, nuts, and peel, providing uniform sweetness and moisture control for confectionery and baking. Infrared candying is better applied to firmer fruits and denser nuts, delivering faster processing times and energy efficiency for industrial-scale production.

Related Important Terms

InfraCandying

Infrared candying accelerates the candying process by using infrared radiation to evenly penetrate and heat the fruit, reducing drying time by up to 50% compared to traditional methods. This technique enhances flavor retention and texture quality while lowering energy consumption, making it a more efficient and sustainable choice for faster candying.

IR Candy Acceleration

Infrared candying accelerates the traditional candying process by using IR radiation to penetrate fruits or other materials faster, significantly reducing drying time and enhancing sugar infusion uniformity. This method increases energy efficiency and preserves the texture and color better compared to conventional candying, enabling high-quality results in a fraction of the time.

Rapid IR Candy Fusion

Rapid IR Candy Fusion employs infrared radiation to penetrate and heat candy ingredients quickly and uniformly, accelerating the candying process compared to traditional methods. This technique enhances flavor infusion, reduces processing time, and maintains product quality through precise temperature control.

Spectral Sugaring

Spectral sugaring enhances candying processes by utilizing targeted infrared wavelengths to accelerate sugar infusion and crystallization, significantly reducing processing time compared to traditional candying methods. Infrared candying optimizes energy absorption and heat distribution, resulting in a more efficient spectral sugaring technique that preserves texture and flavor while increasing throughput.

Flash Candying

Flash candying leverages intense, short bursts of heat through infrared technology to significantly reduce processing time compared to traditional candying methods. This advanced technique enhances sugar infusion efficiency while preserving the natural texture and flavor of fruits.

Infrared Osmotic Transfer

Infrared candying accelerates the candying process by enhancing osmotic transfer through targeted infrared radiation, which increases the penetration rate of sugar solutions into the fruit. This method significantly reduces processing time compared to traditional candying, improving efficiency and preserving fruit texture and flavor.

Hypercandy Process

The Hypercandy Process leverages infrared candying technology to accelerate sugar crystallization, reducing drying time by up to 50% compared to traditional candying methods. This innovative approach ensures uniform heat distribution and enhanced flavor retention, optimizing production efficiency in confectionery manufacturing.

ThermoSpectral Glazing

ThermoSpectral Glazing enhances candying by utilizing infrared radiation to accelerate heat transfer, resulting in faster sugar infusion and improved product consistency compared to traditional candying methods. This technology optimizes energy efficiency and reduces processing time, delivering superior texture and flavor retention in candied products.

Subsecond Candy Coating

Subsecond candy coating significantly accelerates the candying process by using infrared candying, which penetrates the surface efficiently and reduces the coating time compared to traditional candying methods. Infrared candying enhances heat transfer and enables precise temperature control, resulting in faster processing and improved coating uniformity for confectionery products.

Candying vs Infrared Candying for faster processing. Infographic

cookingdiff.com

cookingdiff.com