Candying citrus peels involves simmering them in sugar syrup until they become tender and translucent, creating a sweet, crystallized coating that enhances flavor and texture. Vacuum glazing, on the other hand, uses low pressure to apply a thin sugar or syrup layer, preserving the peel's natural moisture and color without the intense cooking process. Choosing candying results in a richer, more concentrated sweetness and a softer bite, while vacuum glazing offers a glossier appearance and fresher taste with less alteration to the peel's original structure.

Table of Comparison

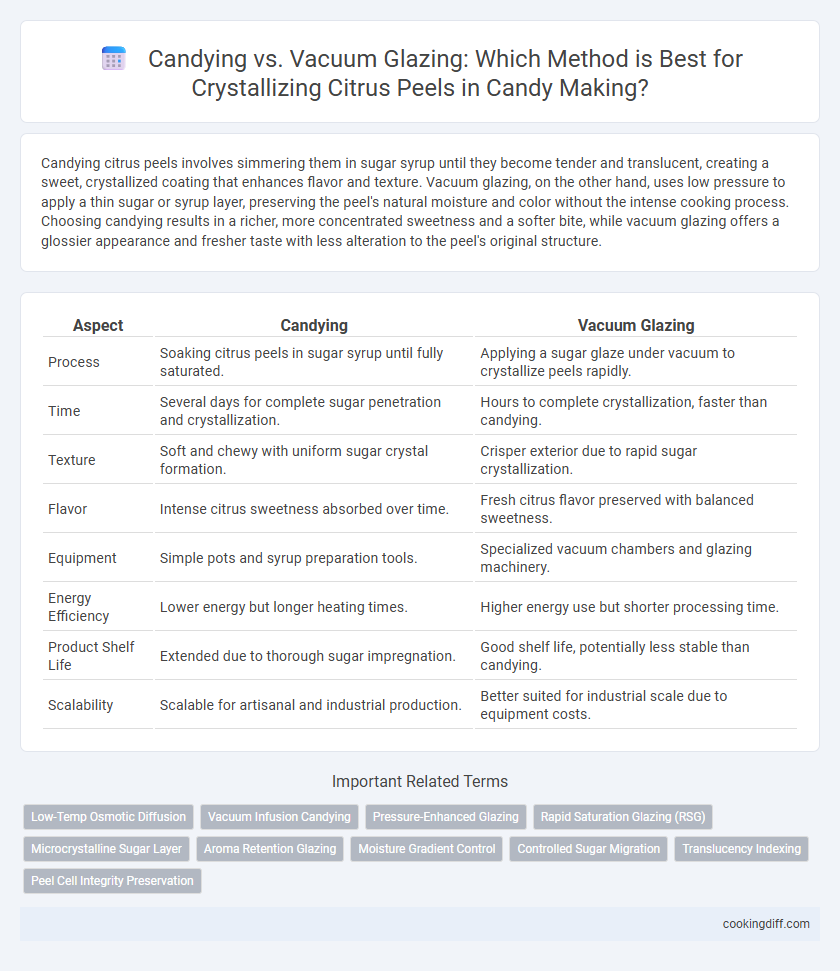

| Aspect | Candying | Vacuum Glazing |

|---|---|---|

| Process | Soaking citrus peels in sugar syrup until fully saturated. | Applying a sugar glaze under vacuum to crystallize peels rapidly. |

| Time | Several days for complete sugar penetration and crystallization. | Hours to complete crystallization, faster than candying. |

| Texture | Soft and chewy with uniform sugar crystal formation. | Crisper exterior due to rapid sugar crystallization. |

| Flavor | Intense citrus sweetness absorbed over time. | Fresh citrus flavor preserved with balanced sweetness. |

| Equipment | Simple pots and syrup preparation tools. | Specialized vacuum chambers and glazing machinery. |

| Energy Efficiency | Lower energy but longer heating times. | Higher energy use but shorter processing time. |

| Product Shelf Life | Extended due to thorough sugar impregnation. | Good shelf life, potentially less stable than candying. |

| Scalability | Scalable for artisanal and industrial production. | Better suited for industrial scale due to equipment costs. |

Introduction to Candying and Vacuum Glazing

Candying and vacuum glazing are two distinct methods used to crystallize citrus peels, enhancing flavor and texture. Candying involves slow cooking peels in sugar syrup until fully saturated, while vacuum glazing uses reduced pressure to apply a thin sugar coating quickly.

- Candying process - Citrus peels are simmered in sugar syrup over several hours to achieve deep sugar penetration and preservation.

- Vacuum glazing technique - A vacuum chamber is used to remove air and condense sugar onto the peels, creating a uniform glaze rapidly.

- Differences in texture - Candying produces soft, richly flavored peels, whereas vacuum glazing results in a crispier, lightly sugared surface.

The Science Behind Candying Citrus Peels

| The Science Behind Candying Citrus Peels |

| Candying citrus peels involves osmotic dehydration, where sugar syrup penetrates the peel cells, replacing water molecules and creating a protective crystallized layer that preserves flavor and texture. Vacuum glazing uses low pressure to accelerate sugar infusion and evaporation, promoting rapid crystallization and enhanced shelf stability. Both methods manipulate water activity and sugar concentration, but candying relies on gradual diffusion, while vacuum glazing applies pressure changes to optimize crystallization kinetics. |

Understanding Vacuum Glazing Techniques

Vacuum glazing is a cutting-edge technique used for crystallizing citrus peels, involving the removal of air from the environment to enhance sugar absorption and preserve the peel's natural texture. This method differs significantly from traditional candying by accelerating the crystallization process and improving the overall quality of the peel.

Understanding vacuum glazing techniques requires knowledge of the vacuum pressure levels and temperature control critical for achieving optimal results. These parameters allow for a more uniform crystallization and a glossy finish that enhances both appearance and flavor retention in candied citrus peels.

Ingredient Preparation: Similarities and Differences

Both candying and vacuum glazing require precise ingredient preparation, starting with selecting fresh citrus peels and blanching them to remove bitterness. Candying traditionally involves soaking peels in sugar syrup over several days to achieve crystallization.

Vacuum glazing, however, uses a controlled vacuum environment to infuse sugar more rapidly and evenly into the citrus peels. This method often demands a more exact sugar solution concentration and peel trimming to optimize the glazing process.

Equipment Needed for Each Method

Candying citrus peels requires basic equipment such as a large pot or saucepan, a stove, and a candy thermometer to monitor the sugar syrup temperature. Vacuum glazing, however, demands specialized vacuum ovens that precisely control pressure and temperature for uniform crystallization.

The candying process relies on conventional kitchen tools and careful manual monitoring, making it accessible for small-scale production. Vacuum glazing uses advanced machinery to create a controlled low-pressure environment, which enhances peel texture and flavor retention. This equipment difference significantly impacts efficiency, product consistency, and scalability in crystallizing citrus peels.

Step-by-Step Process: Candying Citrus Peels

How does the candying process for citrus peels differ from vacuum glazing in crystallization techniques? Candying citrus peels involves simmering the peel in sugar syrup over several stages to gradually replace water content, enhancing sweetness and texture naturally. This method allows for controlled crystallization on the surface, unlike vacuum glazing which uses pressure to seal the peel for preservation and a glossy finish.

Step-by-Step Process: Vacuum Glazing Citrus Peels

Vacuum glazing citrus peels involves coating them with a sugar syrup under reduced pressure to enhance crystallization. This process ensures a uniform and glossy finish compared to traditional candying methods.

- Preparation - Citrus peels are cleaned, blanched, and partially dried before vacuum glazing.

- Syrup Application - A sugar syrup is applied to the peels inside a vacuum chamber to infuse and evenly coat the surface.

- Vacuum Process - The chamber pressure is reduced, promoting syrup penetration and creating a shiny, crystallized glaze.

Texture and Flavor Comparison

Candying produces citrus peels with a firm, slightly chewy texture and a sweet, intense flavor due to prolonged sugar infusion. Vacuum glazing results in a smoother, more tender peel with a subtler flavor, preserving the natural citrus notes more effectively.

- Candying Texture - Firm and chewy, ideal for a pronounced bite.

- Vacuum Glazing Texture - Smooth and tender, enhancing palatability.

- Flavor Profile - Candying intensifies sweetness, while vacuum glazing retains delicate citrus aromas.

Choosing between candying and vacuum glazing depends on desired texture intensity and flavor concentration in crystallized citrus peels.

Shelf Life and Storage Considerations

Candying citrus peels extends shelf life by creating a high sugar concentration that inhibits microbial growth, allowing storage for several months at room temperature. Vacuum glazing forms a thin, protective sugar coating through rapid dehydration, offering shorter shelf life but improved immediate preservation and flavor retention. Proper storage for both methods involves cool, dry conditions away from direct sunlight to maintain texture and prevent spoilage.

Related Important Terms

Low-Temp Osmotic Diffusion

Low-temp osmotic diffusion in candying enhances the gradual sugar penetration into citrus peels, preserving their cellular structure and flavor during crystallization. Vacuum glazing accelerates moisture removal but may disrupt osmotic balance, resulting in less uniform sugar absorption compared to traditional candying techniques.

Vacuum Infusion Candying

Vacuum infusion candying enhances crystallization of citrus peels by efficiently infusing sugar syrup under reduced pressure, resulting in faster, more uniform sugar penetration and superior texture compared to traditional vacuum glazing methods. This technique preserves the peel's natural flavor and color while reducing soaking time and improving shelf life through better syrup absorption at the cellular level.

Pressure-Enhanced Glazing

Pressure-enhanced glazing uses controlled vacuum pressure to accelerate the crystallization of citrus peels, creating a uniform, glossy sugar coating that enhances texture and flavor compared to traditional candying methods. This technique improves sugar infusion and moisture retention, resulting in superior peel candied quality with reduced processing time.

Rapid Saturation Glazing (RSG)

Rapid Saturation Glazing (RSG) accelerates crystallization in candying citrus peels by quickly infusing sugar solutions, outperforming traditional vacuum glazing in efficiency and uniformity of sugar coating. RSG enhances texture and shelf life by creating a consistent crystallized layer, reducing processing time without compromising flavor retention.

Microcrystalline Sugar Layer

Candying citrus peels forms a microcrystalline sugar layer through slow sugar infusion, creating a firm, glossy coating that preserves texture and flavor. Vacuum glazing accelerates crystallization by reducing pressure, producing a uniform microcrystalline layer that enhances shelf stability and visual appeal.

Aroma Retention Glazing

Candying preserves citrus peel aroma through slow sugar infusion, enhancing natural fragrance retention. Vacuum glazing locks in volatile aromatic compounds by creating a low-pressure seal, resulting in superior aroma preservation compared to traditional candying methods.

Moisture Gradient Control

Candying uses a gradual sugar infusion process that naturally controls moisture gradient, ensuring even crystallization of citrus peels. Vacuum glazing, by contrast, accelerates moisture removal under low pressure, offering precise control but potentially creating uneven drying and crystallization.

Controlled Sugar Migration

Candying ensures controlled sugar migration by gradually infusing citrus peels with sugar syrup over extended periods, resulting in a uniform crystallized texture. Vacuum glazing accelerates sugar absorption under reduced pressure, offering faster crystallization but with less precise control over sugar migration compared to traditional candying methods.

Translucency Indexing

Candying citrus peels enhances translucency by infusing sugar crystals that absorb and reflect light, resulting in a glossy, semi-transparent appearance. Vacuum glazing improves translucency further by removing air pockets, creating a uniform crystalline structure that maximizes light transmission and clarity.

Candying vs Vacuum Glazing for crystallizing citrus peels. Infographic

cookingdiff.com

cookingdiff.com