Candying preserves foods by slowly cooking them in sugar syrup, resulting in a chewy texture and intensified sweetness. Freeze-dried candying, on the other hand, removes moisture through sublimation, maintaining the original shape and flavor while creating a light, crispy texture ideal for cooking applications that require quick rehydration. Both methods enhance flavor concentration, but freeze-dried candying offers longer shelf life and easier integration into recipes without added moisture.

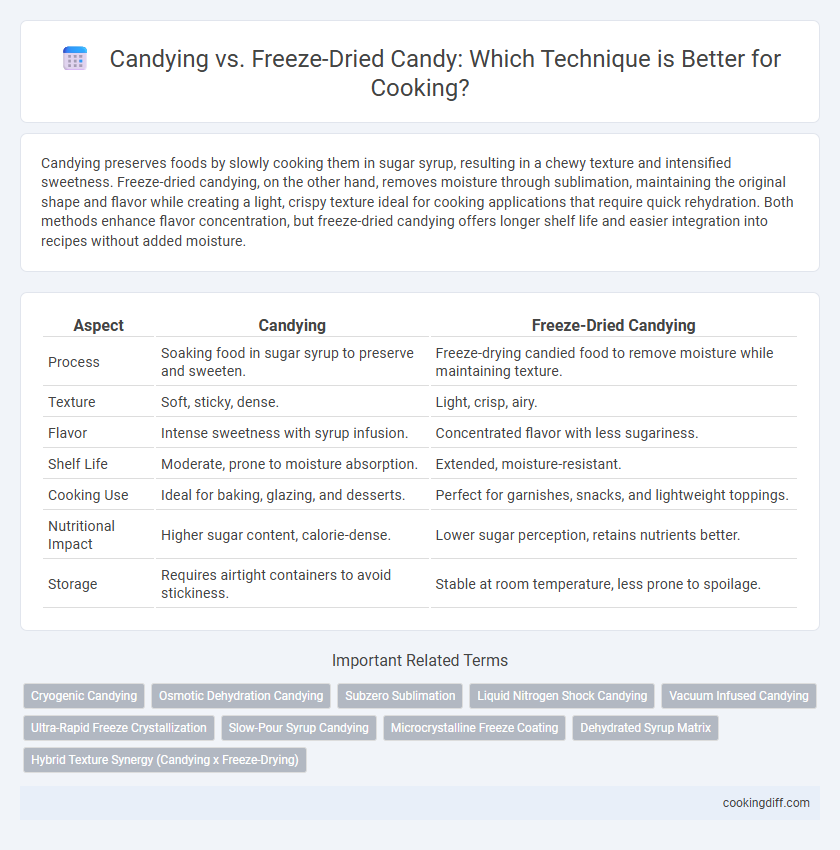

Table of Comparison

| Aspect | Candying | Freeze-Dried Candying |

|---|---|---|

| Process | Soaking food in sugar syrup to preserve and sweeten. | Freeze-drying candied food to remove moisture while maintaining texture. |

| Texture | Soft, sticky, dense. | Light, crisp, airy. |

| Flavor | Intense sweetness with syrup infusion. | Concentrated flavor with less sugariness. |

| Shelf Life | Moderate, prone to moisture absorption. | Extended, moisture-resistant. |

| Cooking Use | Ideal for baking, glazing, and desserts. | Perfect for garnishes, snacks, and lightweight toppings. |

| Nutritional Impact | Higher sugar content, calorie-dense. | Lower sugar perception, retains nutrients better. |

| Storage | Requires airtight containers to avoid stickiness. | Stable at room temperature, less prone to spoilage. |

Introduction to Candying and Freeze-Dried Candying

Candying is a traditional preservation method that involves soaking fruit in sugar syrup to enhance flavor and texture. Freeze-dried candying uses rapid freezing and low-pressure drying to maintain the fruit's structure and nutrients while achieving a crispy texture.

- Candying process - Involves boiling fruit in sugar syrup to replace water content with sugar, preserving sweetness and moisture.

- Freeze-dried candying process - Employs freezing and vacuum drying to remove moisture without high heat, retaining natural flavors and nutrients.

- Usage in cooking - Candied fruits are commonly used in baking and confections, while freeze-dried candying offers lightweight, crunchy ingredients for snacks and garnishes.

What is Traditional Candying?

Traditional candying is a preservation process that involves simmering fruit in a sugar syrup until the fruit is infused and saturated with sugar, creating a sweet, glossy coating. This method removes moisture gradually, allowing the fruit to maintain its original texture and vibrant color while becoming tender and flavorful.

Unlike freeze-dried candying, traditional candying relies on heat and prolonged soaking rather than rapid dehydration, resulting in a denser, chewier product. The process enhances natural sugars and extends shelf life, making it ideal for use in baking, confectionery, and garnishing desserts.

Understanding Freeze-Dried Candying

Freeze-dried candying preserves the natural texture and flavor of fruits by removing moisture through sublimation, resulting in a lightweight, crispy product. Unlike traditional candying, which involves soaking fruit in sugar syrup, freeze-dried candying retains more nutrients and offers a distinct crunch.

- Freeze-drying process - Removes water content by freezing and applying vacuum, preserving the fruit's structure.

- Retention of nutrients - Maintains higher levels of vitamins and antioxidants compared to traditional candying methods.

- Texture and flavor - Produces a crunchy texture with concentrated fruit flavor, ideal for modern culinary applications.

Key Differences Between Candying and Freeze-Dried Candying

Candying involves preserving fruits or vegetables by immersing them in sugar syrup, which enhances flavor and texture. Freeze-dried candying removes moisture through freezing and vacuum drying, resulting in a lightweight, crisp product with intensified natural taste.

- Texture - Candying creates a chewy, sticky surface, while freeze-dried candying produces a crisp, airy texture.

- Moisture Content - Candying retains a higher moisture content due to syrup absorption, whereas freeze-dried candying significantly reduces moisture for longer shelf life.

- Flavor Concentration - Freeze-dried candying intensifies natural flavors by removing water, unlike candying which adds sweetness from sugar.

Both techniques offer unique culinary benefits that can enrich diverse cooking applications.

Texture and Flavor Profiles Compared

How do texture and flavor profiles differ between candying and freeze-dried candying for cooking? Candying preserves a chewy, rich texture with intensified sweetness and deep caramel notes, enhancing desserts with a traditional mouthfeel. Freeze-dried candying creates a light, crispy texture and concentrates flavors into a tart, vibrant profile, ideal for adding a unique crunch and freshness to dishes.

Preservation and Shelf Life: Which Lasts Longer?

Candying preserves fruits by infusing them with sugar, which inhibits microbial growth and extends shelf life to several months when stored properly. Freeze-dried candying removes moisture through sublimation, resulting in a lightweight product with significantly longer shelf life, often lasting up to a year or more.

The high sugar content in traditional candying acts as a natural preservative, but moisture retention can limit longevity compared to freeze-dried counterparts. Freeze-dried candying drastically reduces water activity, preventing microbial spoilage and enzymatic reactions more effectively. For extended storage and optimal preservation, freeze-dried candying offers superior shelf life while maintaining flavor and texture in cooking applications.

Culinary Uses: When to Use Each Method

Candying preserves fruit by immersing it in sugar syrup, enhancing flavor and texture, ideal for baking and garnishing desserts. Freeze-dried candying removes moisture rapidly, retaining fruit shape and nutrients, perfect for crunchy toppings and snack additions.

Choose traditional candying for recipes requiring soft, chewy ingredients like fruitcakes or tarts. Opt for freeze-dried candying when a crispy texture and extended shelf life are desired in cereals, trail mixes, or gourmet chocolates.

Nutritional Value in Both Methods

Candying preserves the natural sugars in fruits but often results in a higher calorie content due to added sugar, which can reduce the overall nutritional value. Freeze-dried candying retains most vitamins and minerals by removing moisture without using heat, maintaining a lower sugar concentration and better nutrient density. Both methods improve shelf life, but freeze-dried candying offers a healthier alternative with enhanced preservation of antioxidants and fiber.

Pros and Cons: Candying vs Freeze-Dried Candying

Candying preserves fruit by soaking it in sugar syrup, enhancing flavor and texture but increasing sugar content and cooking time. Freeze-dried candying removes moisture through freezing and vacuum drying, retaining nutrients and crispness while offering longer shelf life and lighter texture. Candying suits rich desserts needing moist sweetness, while freeze-drying benefits snacks requiring crunch and portability.

Related Important Terms

Cryogenic Candying

Cryogenic candying utilizes ultra-low temperatures to preserve fruit texture and flavor by rapidly freezing and infusing sugar, offering superior retention of moisture and nutrients compared to traditional candying methods. This process combines freeze-dried candying advantages with candying's sweetness, enhancing culinary versatility and extending shelf life without sacrificing natural taste or color.

Osmotic Dehydration Candying

Osmotic dehydration candying preserves flavor and texture by soaking fruit in sugar syrup, which gradually removes water content while maintaining structural integrity and enhancing sweetness. Unlike freeze-dried candying that rapidly removes moisture through sublimation, osmotic dehydration offers a slower, energy-efficient method that improves shelf life and results in a chewier, more natural-tasting product.

Subzero Sublimation

Candying involves preserving fruits by soaking them in sugar syrup, enhancing flavor and texture, while freeze-dried candying uses subzero sublimation to remove moisture under low temperatures, maintaining the fruit's shape and nutrients more effectively. Subzero sublimation in freeze-dried candying prevents ice crystal formation, resulting in a lighter, crispier texture ideal for gourmet cooking applications.

Liquid Nitrogen Shock Candying

Liquid nitrogen shock candying rapidly freezes fruits or vegetables, preserving texture and flavor better than traditional candying or freeze-dried methods by preventing ice crystal formation. This technique enhances culinary applications by maintaining vibrant colors and nutrient content while delivering a crisp, intense sweetness ideal for gourmet presentations.

Vacuum Infused Candying

Vacuum infused candying enhances flavor penetration and texture by using reduced pressure to draw syrup deeply into fruits, outperforming traditional candying methods in efficiency and consistency. Compared to freeze-dried candying, vacuum infusion maintains moisture and vibrant color while achieving a tender, perfectly preserved product ideal for cooking applications.

Ultra-Rapid Freeze Crystallization

Ultra-rapid freeze crystallization in candying preserves the natural texture and flavor of fruits more effectively than traditional candying methods by minimizing moisture loss and enzymatic degradation. Freeze-dried candying further enhances shelf life and nutrient retention, creating lightweight, crispy confections ideal for gourmet cooking applications.

Slow-Pour Syrup Candying

Slow-pour syrup candying preserves the texture and natural flavors of fruits by gradually infusing them with sugar, enhancing moisture retention and preventing crystallization. Compared to freeze-dried candying, this method delivers a richer, more succulent taste ideal for culinary applications requiring tender, syrup-coated ingredients.

Microcrystalline Freeze Coating

Candying preserves fruits by simmering in sugar syrup, enhancing flavor and shelf life, while freeze-dried candying uses sublimation to remove moisture, retaining texture and nutrients. Microcrystalline freeze coating in freeze-dried candying creates a delicate sugar film that improves crispness and extends freshness without added preservatives.

Dehydrated Syrup Matrix

Candying creates a dense, sugary syrup matrix that encapsulates fruit, resulting in a chewy texture and intensified sweetness. Freeze-dried candying removes moisture rapidly without forming a syrup matrix, preserving the fruit's natural flavor and crispness while producing a lighter, more porous texture ideal for delicate culinary applications.

Candying vs Freeze-Dried Candying for cooking. Infographic

cookingdiff.com

cookingdiff.com