Candying enhances fruit texture by gently infusing sugar, creating a firm yet tender consistency. Ultrasound-assisted candying accelerates the process, promoting deeper sugar penetration and more uniform texture development. This technique improves overall product quality by preserving cellular structure while reducing processing time.

Table of Comparison

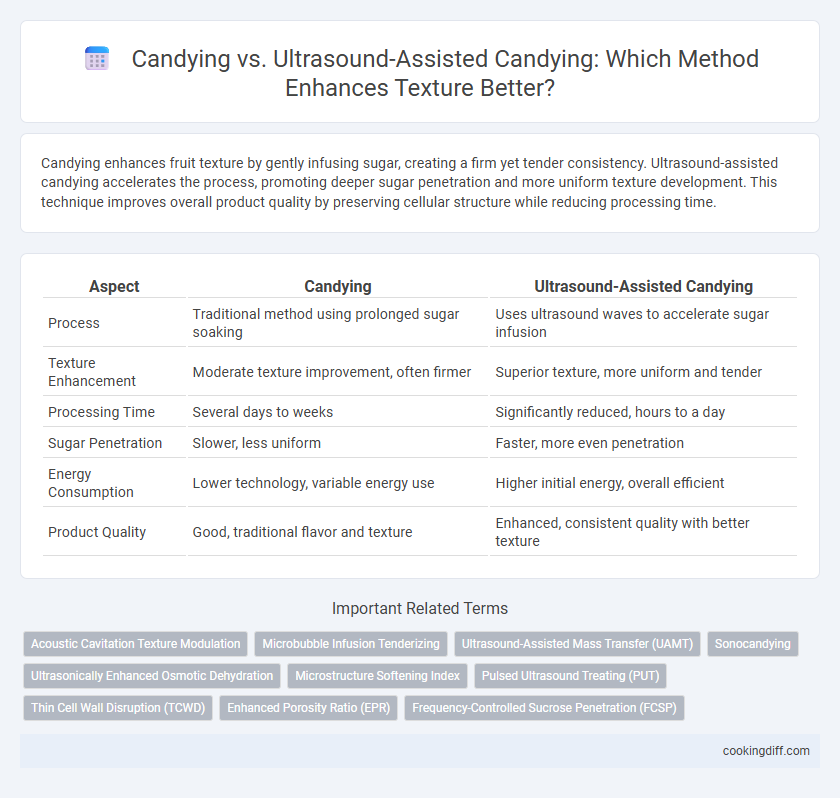

| Aspect | Candying | Ultrasound-Assisted Candying |

|---|---|---|

| Process | Traditional method using prolonged sugar soaking | Uses ultrasound waves to accelerate sugar infusion |

| Texture Enhancement | Moderate texture improvement, often firmer | Superior texture, more uniform and tender |

| Processing Time | Several days to weeks | Significantly reduced, hours to a day |

| Sugar Penetration | Slower, less uniform | Faster, more even penetration |

| Energy Consumption | Lower technology, variable energy use | Higher initial energy, overall efficient |

| Product Quality | Good, traditional flavor and texture | Enhanced, consistent quality with better texture |

Introduction to Candying Techniques

Candying involves preserving fruits by soaking them in sugar syrup, which enhances flavor and texture through gradual sugar infusion. Ultrasound-assisted candying accelerates this process by using sound waves to improve syrup penetration and reduce treatment time. This innovative technique results in a more uniform texture and better retention of the fruit's structural integrity compared to traditional candying methods.

Understanding Traditional Candying

Traditional candying involves slow immersion of fruits in sugar syrup, allowing gradual sugar penetration and moisture reduction that enhances texture and flavor. This method relies on diffusion principles, where sugar concentration gradients enable preservation and firmness retention over time. While effective, traditional candying can be time-consuming and may result in uneven texture compared to modern techniques like ultrasound-assisted candying.

Basics of Ultrasound-Assisted Candying

Ultrasound-Assisted Candying utilizes high-frequency sound waves to enhance the infusion of sugar into fruits, resulting in improved texture and reduced processing time. This technique causes cavitation, which creates microscopic channels in the fruit, allowing for faster and more uniform sugar penetration.

Unlike traditional candying methods that rely solely on osmotic pressure, ultrasound-assisted candying accelerates mass transfer and preserves fruit firmness. The process minimizes cellular damage, maintaining the original fruit structure while enhancing crispness. This leads to a superior texture and an overall higher quality product compared to conventional candying.

Texture Enhancement: A Comparative Overview

Candying enhances fruit texture by infusing sugar syrup, resulting in a firmer and chewier consistency through osmotic dehydration. Ultrasound-assisted candying accelerates mass transfer, producing a more uniform texture with improved tenderness and reduced processing time.

Traditional candying often leads to uneven texture due to slower sugar penetration, while ultrasound promotes better sugar diffusion and cellular structure preservation. This advanced technique minimizes tissue damage, enhancing texture quality and extending shelf life compared to conventional methods.

Mechanisms Behind Texture Improvement

| Mechanism | Candying | Ultrasound-Assisted Candying |

| Mass Transfer | Relies on diffusion-driven sugar infiltration into fruit tissues, gradually replacing water content. | Ultrasound induces cavitation and microstreaming, accelerating sugar penetration by disrupting cell walls. |

| Texture Enhancement | Maintains firmness by osmotic dehydration but may lead to cell shrinkage over long times. | Preserves cellular integrity and elasticity by reducing processing time and minimizing thermal damage. |

| Microstructural Changes | Causes slight cell wall contraction and limited porosity increase. | Promotes micro-channel formation and enhances cell wall permeability, improving texture softness without compromising strength. |

Time and Efficiency in Both Methods

Candying typically requires extended soaking periods to achieve desired texture, whereas ultrasound-assisted candying significantly reduces processing time by enhancing mass transfer. The efficiency of ultrasound waves accelerates sugar penetration, resulting in improved texture in a shorter duration.

- Extended Soaking - Traditional candying involves prolonged immersion in sugar syrup to modify texture gradually.

- Ultrasound Acceleration - Ultrasound waves enhance cellular permeability, leading to faster sugar absorption and texture enhancement.

- Time Efficiency - Ultrasound-assisted candying decreases processing time by up to 50%, optimizing production efficiency.

Nutrient Retention and Quality

Candying enhances fruit texture but may cause nutrient loss due to prolonged heat exposure. Ultrasound-assisted candying improves texture uniformly while better preserving vitamins and antioxidants.

- Nutrient Retention - Ultrasound-assisted candying reduces processing time, minimizing degradation of heat-sensitive nutrients like vitamin C.

- Texture Uniformity - Ultrasonic waves facilitate deeper syrup penetration, resulting in more consistent texture throughout the fruit.

- Product Quality - Ultrasound maintains fruit firmness and color better than traditional candying methods, enhancing overall sensory appeal.

Ultrasound-assisted candying offers a superior approach for nutrient preservation and texture quality in candied fruits.

Sensory Attributes: Taste and Mouthfeel

Candying enhances food texture through traditional sugar infusion, resulting in a sweet, dense mouthfeel with rich taste complexity. Ultrasound-assisted candying improves diffusion rates, producing a more uniform texture with intensified flavor profiles and softer bite characteristics.

- Enhanced Sweetness - Ultrasound accelerates sugar penetration, intensifying the overall sweetness compared to conventional candying.

- Improved Mouthfeel - Ultrasound-assisted methods create a tender, less chewy texture by disrupting cellular structures.

- Flavor Uniformity - Ultrasound promotes even distribution of flavors, leading to consistent taste throughout the candied product.

Industrial Applications and Scalability

How do industrial applications of candying compare to ultrasound-assisted candying in terms of scalability and texture enhancement? Traditional candying methods offer widespread industrial use but often encounter limitations in achieving consistent texture and longer processing times. Ultrasound-assisted candying enhances scalability by accelerating sugar infusion and improving fruit texture uniformity, making it a more efficient option for large-scale food production.

Related Important Terms

Acoustic Cavitation Texture Modulation

Acoustic cavitation generated during ultrasound-assisted candying significantly enhances texture modulation by promoting uniform syrup penetration and disrupting cell walls, resulting in a more tender and evenly textured product compared to conventional candying. This cavitation effect accelerates mass transfer and maintains structural integrity, leading to improved chewiness and reduced hardness in candied fruits.

Microbubble Infusion Tenderizing

Microbubble infusion during ultrasound-assisted candying significantly enhances texture by promoting deeper tenderizing and improved flavor absorption compared to traditional candying methods. This technique increases cell wall permeability, resulting in a more uniform, tender product with superior sensory attributes.

Ultrasound-Assisted Mass Transfer (UAMT)

Ultrasound-Assisted Mass Transfer (UAMT) significantly enhances candying by accelerating solute diffusion and improving texture uniformity through cavitation and microstreaming effects. Compared to traditional candying, UAMT reduces processing time while producing a firmer, more consistent texture in candied fruits and confections.

Sonocandying

Sonocandying leverages ultrasound waves to enhance mass transfer, resulting in improved texture and faster infusion of sugar compared to traditional candying methods. This innovative technique promotes better cell structure retention and uniformity, leading to a tender yet firm product with superior sensory attributes.

Ultrasonically Enhanced Osmotic Dehydration

Ultrasonically enhanced osmotic dehydration significantly improves texture by accelerating mass transfer and reducing processing time compared to traditional candying methods. This technique preserves cellular integrity, resulting in a firmer, more desirable texture in the final candied product.

Microstructure Softening Index

Candying with ultrasound-assisted techniques significantly improves texture by enhancing the Microstructure Softening Index, leading to softer and more evenly textured products. Conventional candying methods exhibit lower softening indices, resulting in firmer, less uniformly softened microstructures.

Pulsed Ultrasound Treating (PUT)

Pulsed Ultrasound Treating (PUT) significantly enhances the candying process by improving mass transfer rates, resulting in better texture uniformity and reduced processing time compared to traditional candying methods. The mechanical effects of PUT facilitate deeper syrup penetration and maintain fruit firmness, leading to superior texture quality in candied products.

Thin Cell Wall Disruption (TCWD)

Candying relies on traditional osmotic dehydration for texture enhancement, while Ultrasound-Assisted Candying (UAC) significantly improves Thin Cell Wall Disruption (TCWD) by using ultrasonic waves to create microchannels in the fruit tissue. This enhanced TCWD accelerates sugar infiltration and moisture removal, resulting in a firmer, more uniformly textured product with superior flavor retention.

Enhanced Porosity Ratio (EPR)

Ultrasound-assisted candying significantly increases the Enhanced Porosity Ratio (EPR), resulting in a more porous texture compared to traditional candying methods. This elevated EPR improves flavor absorption and reduces processing time, leading to superior texture enhancement in candied products.

Candying vs Ultrasound-Assisted Candying for texture enhancement. Infographic

cookingdiff.com

cookingdiff.com