Candying preserves fruits by infusing them with sugar, which creates a protective barrier that inhibits microbial growth, significantly extending shelf life compared to fresh produce. Dehydrated candies remove moisture through drying processes, reducing water activity to prevent spoilage but may result in a firmer texture and slightly shorter shelf stability than candying. Both methods effectively prolong shelf life, but candying generally offers superior preservation due to its sugar saturation and moisture retention.

Table of Comparison

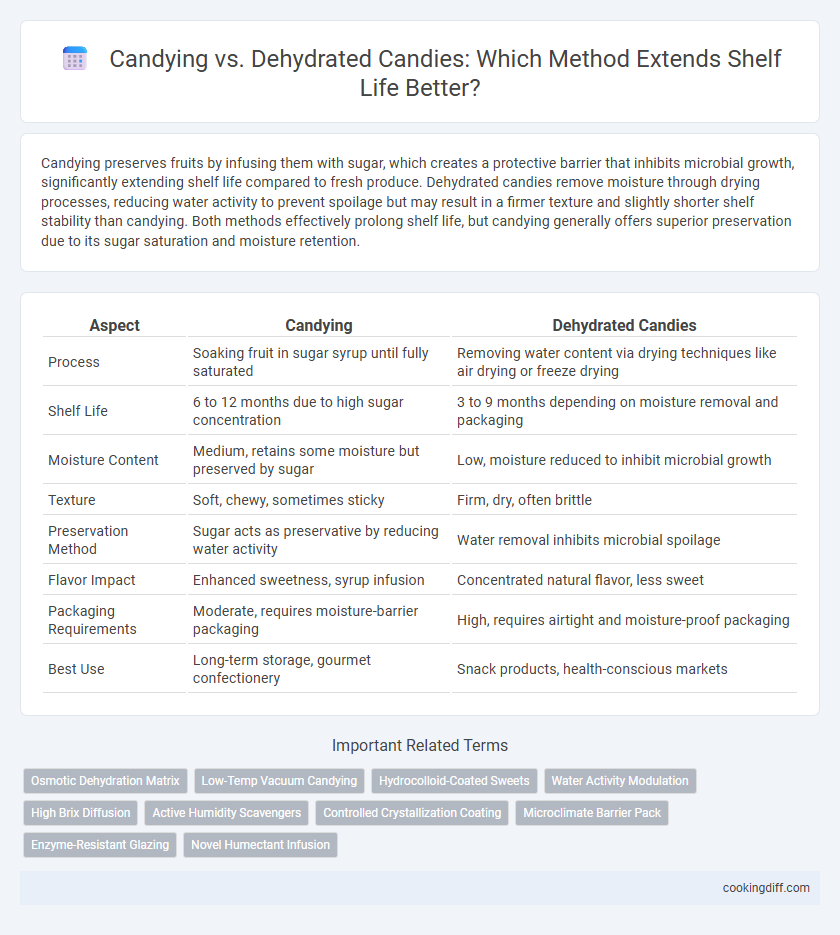

| Aspect | Candying | Dehydrated Candies |

|---|---|---|

| Process | Soaking fruit in sugar syrup until fully saturated | Removing water content via drying techniques like air drying or freeze drying |

| Shelf Life | 6 to 12 months due to high sugar concentration | 3 to 9 months depending on moisture removal and packaging |

| Moisture Content | Medium, retains some moisture but preserved by sugar | Low, moisture reduced to inhibit microbial growth |

| Texture | Soft, chewy, sometimes sticky | Firm, dry, often brittle |

| Preservation Method | Sugar acts as preservative by reducing water activity | Water removal inhibits microbial spoilage |

| Flavor Impact | Enhanced sweetness, syrup infusion | Concentrated natural flavor, less sweet |

| Packaging Requirements | Moderate, requires moisture-barrier packaging | High, requires airtight and moisture-proof packaging |

| Best Use | Long-term storage, gourmet confectionery | Snack products, health-conscious markets |

Introduction to Shelf-Life Extension in Candies

Candying and dehydration are two popular techniques used to extend the shelf life of fruits in confections. Candying involves soaking fruit in sugar syrup, creating a protective barrier that inhibits microbial growth and moisture loss.

Dehydrated candies rely on removing water content to reduce spoilage and enzymatic activity over time. Both methods enhance preservation but differ in texture, flavor retention, and moisture levels, influencing the final product's shelf stability.

What is Candying?

Candiyng is a preservation method that involves soaking fruits in sugar syrup to replace water content, enhancing shelf life and flavor. This technique maintains fruit texture better than dehydration, making it popular for gourmet and decorative confectionery items.

- Water Replacement - Candying replaces water in fruit cells with sugar, preventing microbial growth and spoilage.

- Texture Preservation - The process retains a chewy, tender texture unlike dehydration, which often results in a tougher product.

- Shelf Life Extension - High sugar concentration in candied fruits creates a hostile environment for bacteria, significantly extending shelf life.

Understanding Dehydrated Candies

Dehydrated candies undergo a moisture removal process that significantly reduces water activity, which inhibits microbial growth and extends shelf life compared to traditional candying. This method preserves flavor and texture by maintaining structural integrity while preventing crystallization and spoilage. The enhanced preservation achieved through dehydration makes these candies ideal for long-term storage and distribution in varied climates.

Chemical Changes During Candying

| Chemical Changes During Candying |

| Candying involves infusion of sugar into fruit, increasing sucrose concentration which reduces water activity and inhibits microbial growth, significantly extending shelf life. This process also induces Maillard reactions and caramelization, enhancing flavor complexity and color stability. In contrast, dehydration removes water content primarily through evaporation, concentrating sugars but causing less pronounced chemical transformations, making candied products more chemically stable over extended storage periods. |

Moisture Reduction in Dehydrated Candies

Dehydrated candies achieve moisture reduction through drying processes, significantly lowering water activity and thus inhibiting microbial growth. This enhanced moisture control extends shelf-life more effectively than candying alone, which relies on sugar saturation to preserve. Lower moisture content in dehydrated candies results in a firmer texture and improved stability during storage.

Microbial Stability: Candying vs Dehydration

Candying preserves fruits by infusing them with sugar, which creates a high osmotic pressure environment that inhibits microbial growth. This method enhances microbial stability by reducing water activity, making candied products less susceptible to spoilage.

Dehydration removes moisture entirely to extend shelf life, significantly lowering microbial risk by creating an inhospitable environment for bacteria and mold. Compared to candying, dehydration typically results in longer shelf life due to lower residual moisture content. Both methods effectively reduce microbial growth, but candying combines preservation with added sweetness and texture enhancement.

Texture and Flavor Comparison

Candied fruits maintain a soft and chewy texture that preserves natural flavors more effectively, while dehydrated candies often become tougher and lose some flavor complexity due to moisture removal. The sugar crystallization in candying acts as a natural preservative, enhancing shelf-life without significantly compromising taste.

- Texture retention in candying - Candied fruits remain pliable and moist, providing a more appealing sensory experience than dehydrated counterparts.

- Flavor intensity - Candying preserves inherent fruit flavors better by infusing sugar, whereas dehydration can diminish volatile flavor compounds.

- Shelf-life extension - The sugar saturation in candying inhibits microbial growth, ensuring longer freshness compared to the drying process.

Storage Conditions and Packaging Needs

How do storage conditions and packaging needs differ between candying and dehydrated candies for shelf-life extension? Candying requires airtight packaging with moisture barriers to prevent sugar crystallization and maintain texture, thriving in cool, dry environments. Dehydrated candies demand similar moisture control but benefit from vacuum-sealed or nitrogen-flushed packaging to avoid oxidation and extend freshness longer.

Shelf-Life Outcomes: Candying vs Dehydrated Candies

Candying extends shelf life by replacing moisture in fruits with sugar, creating a barrier against microbial growth and enzymatic reactions. This method maintains texture and flavor for several months under proper storage conditions.

Dehydrated candies reduce water content extensively, leading to longer shelf life due to low moisture activity but often result in a harder texture and altered taste. Shelf stability in dehydrated candies can exceed that of candied fruits, especially in low-humidity environments.

Related Important Terms

Osmotic Dehydration Matrix

Candying extends shelf life by saturating fruit tissues with sugar through osmotic dehydration, creating a stable osmotic dehydration matrix that inhibits microbial growth and enzymatic activity. In contrast, dehydrated candies rely primarily on moisture removal, which may not establish as effective an osmotic matrix for prolonged preservation.

Low-Temp Vacuum Candying

Low-Temp Vacuum Candying significantly prolongs the shelf life of fruits by reducing moisture content at lower temperatures, preserving flavor and nutritional quality better than traditional dehydration methods. This technique minimizes thermal degradation and oxidative damage, resulting in candies with improved texture and extended storage stability compared to conventional dehydrated candies.

Hydrocolloid-Coated Sweets

Hydrocolloid-coated sweets maintain moisture while providing a protective barrier against microbial growth, significantly extending shelf-life compared to dehydrated candies that lose water content and become brittle. The candying process preserves texture and flavor by embedding hydrocolloids, which also improve stability and prevent crystallization over extended storage periods.

Water Activity Modulation

Candying extends shelf life by reducing water activity through sugar saturation, creating a hostile environment for microbial growth, whereas dehydrated candies achieve shelf-life extension primarily by moisture removal but may retain higher water activity levels. The superior water activity modulation in candying results in enhanced preservation and longer storage stability compared to dehydrated counterparts.

High Brix Diffusion

Candying extends shelf-life by utilizing high Brix diffusion, which infuses sugar into the fruit cells, creating a dense, low-moisture environment that inhibits microbial growth more effectively than dehydration. Unlike dehydrated candies that primarily remove water, candying's sugar saturation preserves texture and flavor while significantly enhancing product stability.

Active Humidity Scavengers

Active humidity scavengers in candying significantly enhance shelf-life extension by effectively absorbing moisture, preventing microbial growth and texture degradation. Compared to dehydrated candies, candying with active humidity control maintains optimal taste and structural integrity while reducing the risk of spoilage during storage.

Controlled Crystallization Coating

Controlled Crystallization Coating in candying creates a protective sugar layer that inhibits moisture loss and microbial growth, significantly extending the shelf life compared to dehydrated candies that rely solely on water removal. This coating maintains texture and flavor stability by preventing surface crystallization and moisture absorption, ensuring longer-lasting freshness.

Microclimate Barrier Pack

Candying effectively preserves fruit by creating a microclimate barrier through sugar saturation, significantly extending shelf life by inhibiting microbial growth and moisture loss. In contrast, dehydrated candies rely primarily on moisture removal, which can lead to texture degradation, whereas candying maintains flavor and structural integrity within the microclimate barrier pack.

Enzyme-Resistant Glazing

Candying preserves fruits by saturating them with sugar, creating an enzyme-resistant glazing that enhances shelf-life by inhibiting microbial activity and enzymatic degradation. In contrast, dehydrated candies rely on moisture removal but lack the protective sugar matrix, resulting in a shorter shelf-life and increased susceptibility to enzymatic breakdown.

Candying vs Dehydrated Candies for shelf-life extension. Infographic

cookingdiff.com

cookingdiff.com