Hand-crafted candying of berries involves meticulous manual coating, preserving the natural texture and enhancing the fruit's original flavor with artisanal precision. Ultrasonic candying uses high-frequency sound waves to accelerate sugar infusion, resulting in a uniform sweetness and a crystalline appearance while maintaining the berry's integrity. Both methods optimize berry preservation but differ in texture and processing time, catering to different quality preferences.

Table of Comparison

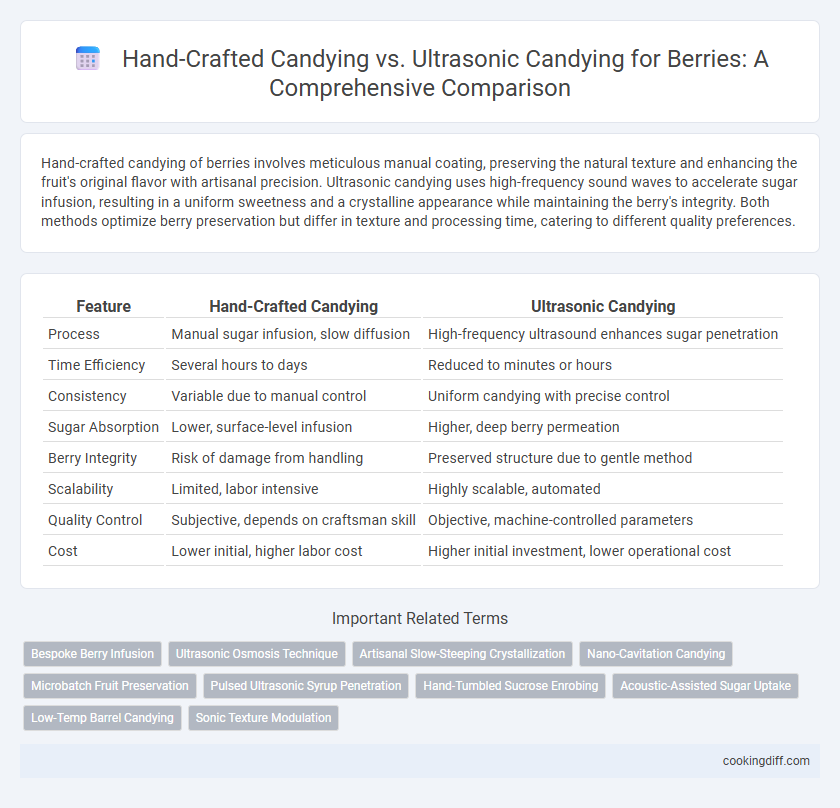

| Feature | Hand-Crafted Candying | Ultrasonic Candying |

|---|---|---|

| Process | Manual sugar infusion, slow diffusion | High-frequency ultrasound enhances sugar penetration |

| Time Efficiency | Several hours to days | Reduced to minutes or hours |

| Consistency | Variable due to manual control | Uniform candying with precise control |

| Sugar Absorption | Lower, surface-level infusion | Higher, deep berry permeation |

| Berry Integrity | Risk of damage from handling | Preserved structure due to gentle method |

| Scalability | Limited, labor intensive | Highly scalable, automated |

| Quality Control | Subjective, depends on craftsman skill | Objective, machine-controlled parameters |

| Cost | Lower initial, higher labor cost | Higher initial investment, lower operational cost |

Introduction to Candying Methods for Berries

| Hand-Crafted Candying involves meticulous soaking of berries in sugar syrup, allowing natural flavors to infuse while preserving texture through slow dehydration. Ultrasonic Candying employs high-frequency sound waves to enhance sugar penetration, significantly reducing processing time and improving uniformity. Both methods aim to create flavorful, shelf-stable candied berries, but Ultrasonic Candying offers increased efficiency and consistency compared to traditional Hand-Crafted techniques. |

What is Hand-Crafted Candying?

Hand-crafted candying is a traditional preservation method where berries are slowly infused with sugar syrup to maintain their natural texture and flavor. This process involves carefully monitoring temperature and syrup concentration to ensure optimal sugar absorption without compromising the fruit's integrity. The meticulous, artisanal approach enhances the berry's appearance and taste, creating a premium product valued for its authenticity and richness.

How Ultrasonic Candying Works

Ultrasonic candying uses high-frequency sound waves to enhance sugar absorption in berries, resulting in a more uniform sweetness and better texture compared to traditional hand-crafted methods. This technology accelerates the candying process while preserving the berries' natural flavors and nutrients.

- Acoustic Cavitation - Ultrasonic waves generate microscopic bubbles that implode, creating micro-jets which increase cell permeability in berries.

- Improved Sugar Infusion - Enhanced permeability allows sugar solution to penetrate deeper and faster into the berry structure, ensuring consistent candying.

- Reduced Processing Time - The intensified mass transfer speeds up dehydration and sugar absorption, minimizing exposure to heat and preserving berry freshness.

Key Differences Between Hand-Crafted and Ultrasonic Candying

Hand-crafted candying involves a slow infusion of sugar syrup, preserving the natural texture and flavor of berries through traditional methods. Ultrasonic candying uses high-frequency sound waves to accelerate sugar absorption, resulting in a more uniform and quicker candying process.

While hand-crafted candying enhances artisanal quality with subtle texture variations, ultrasonic candying improves efficiency and consistency ideal for large-scale production. The key difference lies in the balance between craftsmanship and technology, impacting flavor intensity and production time.

Flavor and Texture: Comparing Results

Hand-crafted candying preserves the natural flavor and texture of berries through gentle, controlled syrup absorption. Ultrasonic candying enhances penetration speed but may alter berry firmness and flavor intensity more significantly.

- Flavor retention - Hand-crafted methods maintain authentic berry taste with minimal artificial influence.

- Texture quality - Ultrasonic candying can lead to softer berries due to deeper syrup infiltration.

- Processing time - Ultrasonic candying reduces candying duration, impacting flavor and texture development.

Efficiency and Time Considerations

Hand-crafted candying of berries typically requires extended processing times, often several hours to days, due to careful manual application and drying stages. This method, though labor-intensive, allows precise control over sugar crystallization and texture, ensuring artisanal quality.

Ultrasonic candying significantly reduces processing time by enhancing mass transfer and sugar penetration within minutes to hours. This efficiency is achieved through high-frequency sound waves that accelerate crystallization without compromising the delicate structure of the berries.

Equipment and Setup Requirements

Hand-crafted candying of berries requires minimal, traditional equipment such as pots, stirring utensils, and drying racks, making it accessible for small-scale production. Ultrasonic candying involves specialized ultrasonic devices and controlled environment chambers, increasing setup complexity and initial investment.

- Hand-Crafted Equipment - Simple tools like saucepans and mesh trays suffice for manual sugar infusion and drying.

- Ultrasonic Devices - Requires precision ultrasonic generators that emit high-frequency waves to accelerate sugar penetration.

- Environmental Control - Ultrasonic setups often need temperature and humidity regulation for optimal candying results.

Ultrasonic candying demands a more sophisticated and costly setup but offers enhanced efficiency and consistency in berry preservation.

Cost Analysis: Traditional vs. Ultrasonic Candying

Hand-crafted candying of berries typically involves higher labor costs due to manual handling and longer processing times, resulting in increased overall expenses. Ultrasonic candying reduces production time and labor requirements, leading to significant cost savings in large-scale operations. Equipment investment for ultrasonic technology is higher upfront but can be offset by improved efficiency and reduced material waste over time.

Suitability for Different Types of Berries

Hand-crafted candying is ideal for delicate berries like raspberries and blackberries, preserving their natural texture and flavor through gentle sugar infusion. Ultrasonic candying suits firmer berries such as cranberries and blueberries, enabling deeper penetration of syrup without damaging their structure.

Hand-crafted methods offer artisanal quality by carefully controlling sugar crystallization, making them perfect for berries with fragile skins. Ultrasonic candying enhances efficiency and uniformity, providing superior syrup absorption especially for berries with thicker skins. Choosing the right technique depends on berry type, desired texture, and production scale, balancing traditional craftsmanship with technological precision.

Related Important Terms

Bespoke Berry Infusion

Hand-crafted candying allows for bespoke berry infusion by carefully controlling sugar absorption and maintaining the natural texture and flavor of each berry, resulting in a uniquely artisanal taste. Ultrasonic candying enhances infusion efficiency at the cellular level by using high-frequency vibrations to evenly distribute sugar solutions, accelerating the candying process while preserving delicate berry qualities.

Ultrasonic Osmosis Technique

Ultrasonic candying uses high-frequency sound waves to enhance osmosis, allowing berries to absorb sugar syrup more evenly and rapidly compared to traditional hand-crafted candying. This cutting-edge technique preserves the natural texture and flavor of berries while increasing production efficiency and product consistency.

Artisanal Slow-Steeping Crystallization

Hand-crafted candying employs artisanal slow-steeping crystallization, allowing berries to absorb sugar gradually, enhancing flavor depth and preserving texture. Ultrasonic candying accelerates the process using high-frequency waves, but often results in less nuanced sweetness and compromised berry integrity compared to traditional slow-steeping methods.

Nano-Cavitation Candying

Nano-cavitation candying employs ultrasonic waves to create microscopic bubbles that enhance berry infusion, resulting in faster and more uniform sugar absorption compared to traditional hand-crafted candying methods. This advanced technique preserves natural berry texture and flavor while significantly reducing processing time and improving product consistency.

Microbatch Fruit Preservation

Hand-crafted candying preserves the natural texture and flavor of berries through slow, precise sugar infusion, ideal for microbatch fruit preservation ensuring premium quality and artisanal appeal. Ultrasonic candying accelerates sugar absorption by using high-frequency sound waves, enhancing uniformity and retaining nutrients, making it a cutting-edge technique for efficient microbatch production without compromising berry integrity.

Pulsed Ultrasonic Syrup Penetration

Hand-crafted candying relies on traditional soaking methods, which result in slower and less uniform syrup penetration in berries compared to pulsed ultrasonic candying techniques. Pulsed ultrasonic syrup penetration uses high-frequency sound waves to create micro-cavitation in the syrup, enhancing diffusion rates and ensuring deeper, more consistent flavor infusion in a shorter time span.

Hand-Tumbled Sucrose Enrobing

Hand-tumbled sucrose enrobing in candying ensures even sugar crystal coating on berries, preserving their natural texture and enhancing flavor with a delicate, artisanal finish. This traditional method contrasts with ultrasonic candying by offering more control over sugar adhesion and a richer mouthfeel, favored in gourmet berry confections.

Acoustic-Assisted Sugar Uptake

Hand-crafted candying enhances flavor and texture through manual soaking and drying, yet ultrasonic candying significantly improves acoustic-assisted sugar uptake by using high-frequency waves to create micro-channels in berry surfaces, accelerating sugar infusion and preserving berry integrity. This method increases efficiency, uniformity, and sugar penetration depth compared to traditional techniques, resulting in superior taste and extended shelf life.

Low-Temp Barrel Candying

Low-Temp Barrel Candying preserves berry texture and flavor by using gentle heating and slow infusion of sugar, ensuring hand-crafted quality with enhanced natural sweetness and minimal nutrient loss. Ultrasonic Candying accelerates sugar penetration through high-frequency vibrations, enabling faster processing while maintaining berry integrity and freshness, ideal for preserving delicate properties during candying.

Hand-Crafted Candying vs Ultrasonic Candying for berries. Infographic

cookingdiff.com

cookingdiff.com