Glass bowls provide excellent visibility during the candying process, allowing precise monitoring of ingredient blending and temperature changes without risk of chemical reactions. Stainless steel mixing bowls offer superior durability and heat conductivity, ensuring even heat distribution crucial for proper candy texture and preventing hot spots. Choosing between glass and stainless steel depends on whether transparency or heat performance is prioritized in candy making.

Table of Comparison

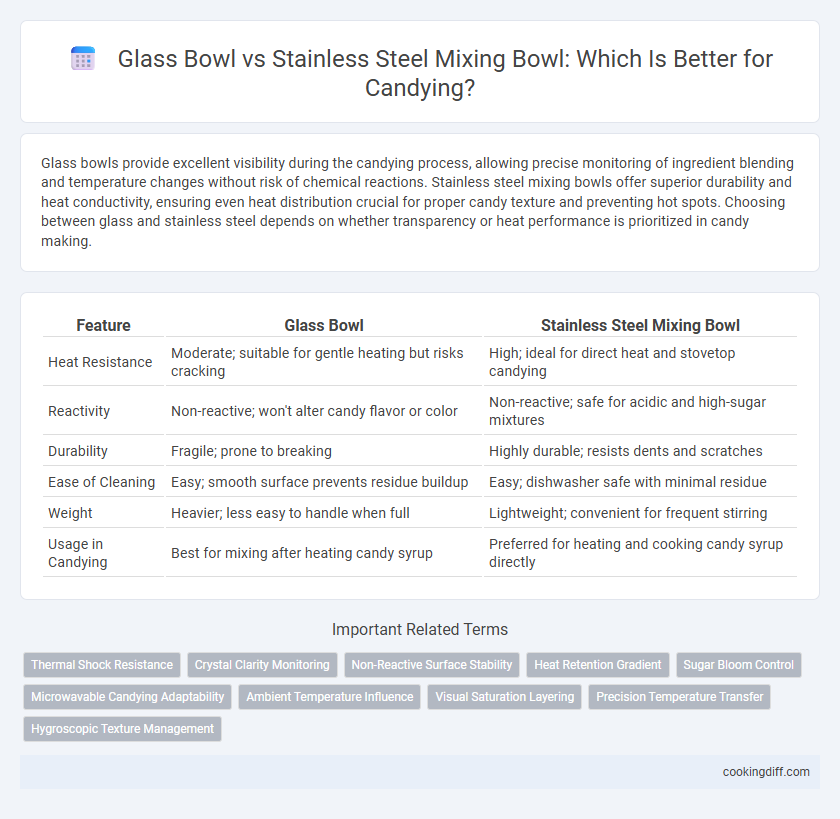

| Feature | Glass Bowl | Stainless Steel Mixing Bowl |

|---|---|---|

| Heat Resistance | Moderate; suitable for gentle heating but risks cracking | High; ideal for direct heat and stovetop candying |

| Reactivity | Non-reactive; won't alter candy flavor or color | Non-reactive; safe for acidic and high-sugar mixtures |

| Durability | Fragile; prone to breaking | Highly durable; resists dents and scratches |

| Ease of Cleaning | Easy; smooth surface prevents residue buildup | Easy; dishwasher safe with minimal residue |

| Weight | Heavier; less easy to handle when full | Lightweight; convenient for frequent stirring |

| Usage in Candying | Best for mixing after heating candy syrup | Preferred for heating and cooking candy syrup directly |

Introduction: Importance of Mixing Bowl Choice in Candying

Choosing the right mixing bowl is crucial in candying as it affects heat distribution and ingredient interaction. Glass bowls offer excellent visibility for monitoring sugar stages, while stainless steel bowls provide superior durability and heat conductivity.

Glass bowls resist acidic ingredients and prevent chemical reactions, making them ideal for delicate candy recipes. Stainless steel bowls tolerate higher temperatures and are less prone to cracking under thermal stress. The selection between glass and stainless steel can significantly impact the texture and consistency of the final candy product.

Material Overview: Glass vs Stainless Steel Bowls

Glass bowls provide a non-reactive surface ideal for acidic candying ingredients, ensuring no flavor alteration. Stainless steel bowls offer excellent heat conduction and durability, making them suitable for frequent use in candy preparation.

- Glass bowl non-reactivity - Prevents chemical reactions with sugar or acid, maintaining pure candy flavor.

- Stainless steel heat conduction - Distributes heat evenly, helping to avoid hot spots during candying.

- Durability comparison - Stainless steel bowls resist breakage and dents, whereas glass bowls are prone to shattering.

Selecting between glass and stainless steel bowls depends on the candying recipe's acidity and the user's preference for durability versus flavor neutrality.

Heat Resistance: Glass Bowl vs Stainless Steel Bowl

Glass bowls offer excellent heat resistance, allowing them to withstand the high temperatures needed for candying without warping or reacting with ingredients. Stainless steel mixing bowls are highly durable and conduct heat efficiently, which can speed up cooking but may cause hot spots when melting sugar. Choosing between glass and stainless steel depends on whether even heat distribution or minimal thermal reactivity is prioritized during the candying process.

Chemical Reactivity: How Bowls Affect Candy Flavors

Glass bowls are non-reactive, ensuring that the candy's flavor remains pure and unaltered during the candying process. This inert quality prevents any metallic taste from seeping into the mixture, preserving the intended sweetness and aroma.

Stainless steel mixing bowls, while durable and easy to clean, can sometimes react with acidic ingredients, subtly impacting the candy's flavor profile. Choosing the right bowl can significantly influence the final taste, making glass a preferred option for flavor-sensitive candy recipes.

Temperature Control and Retention

Which mixing bowl offers better temperature control and retention for candying, glass or stainless steel? Glass bowls provide excellent temperature retention, maintaining consistent heat essential for candying processes. Stainless steel bowls heat and cool quickly, allowing for precise temperature adjustments but less heat retention over time.

Ease of Monitoring Syrup Clarity and Color

| Mixing Bowl Type | Ease of Monitoring Syrup Clarity and Color |

|---|---|

| Glass Bowl | Transparent surface allows clear visibility of syrup color changes, making it easier to monitor caramelization and sugar clarity during candying. |

| Stainless Steel Bowl | Opaque surface limits the ability to observe syrup color and clarity, requiring more frequent stirring or transferring for visual inspection. |

Cleaning and Maintenance Considerations

Glass bowls are non-porous, making them resistant to stains and odors from sugar and flavorings, which simplifies cleaning after candying. They are dishwasher safe and do not react with acidic ingredients, preserving both the bowl's condition and candy's flavor.

Stainless steel mixing bowls offer durability and rust resistance, but require thorough drying to prevent water spots and corrosion, especially after exposure to sugary syrups. Their smooth surface allows for easy manual cleaning, but harsh scrubbing should be avoided to maintain the polished finish.

Durability and Longevity

Stainless steel mixing bowls offer superior durability and resistance to corrosion compared to glass bowls, making them ideal for the high temperatures and frequent stirring involved in candying. Glass bowls are prone to cracking or shattering under thermal stress, which can shorten their lifespan during intense candy-making processes. Investing in stainless steel ensures long-lasting performance and safer handling across multiple candying sessions.

Safety Concerns: Cracking, Warping, and Handling

Glass bowls offer clear visibility during candying but are prone to cracking under rapid temperature changes, posing safety risks. Stainless steel bowls provide superior durability and resistance to warping, enhancing safe handling during high-heat candy preparation.

- Glass bowls can crack - Rapid temperature shifts cause stress fractures that may lead to hazardous breakage.

- Stainless steel resists warping - Metal construction maintains shape despite prolonged exposure to heat, ensuring consistent mixing conditions.

- Handling safety varies - Stainless steel bowls often feature secure grips and lighter weight, reducing accident risks while stirring hot candy mixtures.

Related Important Terms

Thermal Shock Resistance

Glass bowls offer excellent thermal shock resistance, making them less likely to crack or break when exposed to sudden temperature changes during candying. Stainless steel bowls, while durable and versatile, conduct heat quickly and may be more prone to rapid temperature fluctuations that increase the risk of thermal shock.

Crystal Clarity Monitoring

Glass bowls provide superior crystal clarity monitoring during candying, allowing precise observation of sugar stages and color changes without distortion. Stainless steel bowls lack transparency, making it challenging to visually track the candying process and assess sugar development accurately.

Non-Reactive Surface Stability

Glass bowls provide a non-reactive surface ideal for candying, preventing any metallic taste or chemical reaction with acidic ingredients like sugar and lemon juice. Stainless steel mixing bowls offer durable, non-reactive surface stability but must be high-quality, food-grade steel to avoid unwanted metallic interactions during the candying process.

Heat Retention Gradient

Glass bowls provide superior heat retention gradient during candying, ensuring even temperature distribution that reduces hot spots and prevents sugar crystallization. Stainless steel mixing bowls dissipate heat more quickly, requiring more frequent temperature adjustments to maintain consistent candying conditions.

Sugar Bloom Control

Stainless steel mixing bowls offer superior temperature control and non-reactive properties, significantly reducing the risk of sugar bloom during candying compared to glass bowls, which can retain uneven heat and promote crystallization. Using stainless steel ensures a consistent environment for sugar dissolution, preventing premature crystallization and resulting in smoother, glossy candy finishes.

Microwavable Candying Adaptability

Glass bowls offer superior microwavable candying adaptability due to their even heat distribution and non-reactive properties, preventing unwanted flavors or chemical reactions. Stainless steel mixing bowls, while durable, are generally not microwavable and can cause uneven heating, making them less suitable for candying recipes requiring microwave use.

Ambient Temperature Influence

Glass bowls provide superior insulation during candying, maintaining a more stable ambient temperature crucial for precise sugar crystallization. Stainless steel bowls conduct heat rapidly, causing fluctuations in temperature that can affect the consistency and texture of the candy.

Visual Saturation Layering

Glass bowls provide superior visual saturation layering for candying by allowing clear observation of color and texture changes during the cooking process, enhancing precision in sugar crystallization. Stainless steel mixing bowls, while durable and heat-conductive, obscure visual cues due to their opaque surfaces, potentially hindering exact monitoring of saturation levels.

Precision Temperature Transfer

Stainless steel mixing bowls offer superior precision temperature transfer for candying due to their excellent heat conductivity and even heat distribution, ensuring consistent sugar melting and crystallization control. Glass bowls, while convenient for visual monitoring, have slower and less uniform heat transfer, which can result in uneven cooking temperatures during the candying process.

Glass Bowl vs Stainless Steel Mixing Bowl for candying. Infographic

cookingdiff.com

cookingdiff.com